- sales@alummc.com

- Zhengzhou,Henan,China

Alloys:5052,5086,6061,6082,etc

Thickness:3-50 mm

Width:20-2650mm

MOQ:1-3 tons

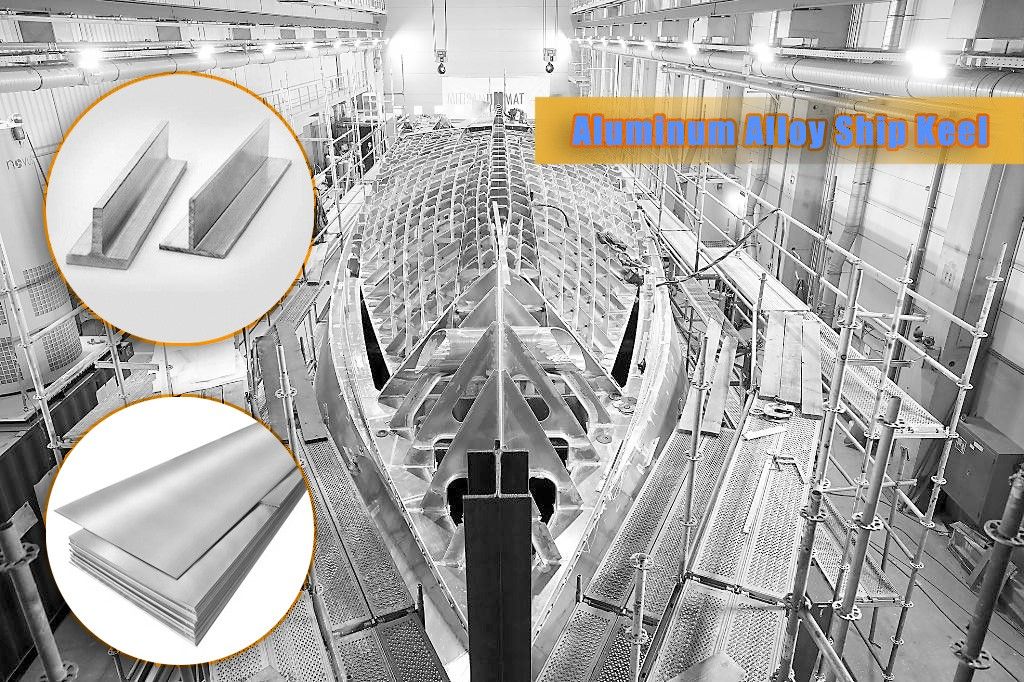

What is "keel"

The keel is a longitudinal member connecting the bow column and the stern column in the center of the base of the hull. It is located at the bottom of the ship. The main function of the ship keel is to bear weight. It is an important load-bearing structure for ships, especially small ships. It bears the longitudinal bending moment of the hull and ensures the structural strength of the ship.

The second function of the keel is to expand the side area of the ship, increase the parallel impedance of the ship in the water, and prevent the side wind from turning. This is especially important for sailing against the wind. The keel on the sailboat will be supported by the diagonal brace in the middle or on the side of the frame. In addition, the keel also plays an important role in the weight stability of the ship, reducing the tilt or reverse rotation of the ship.

In the production of ship keels, aluminum alloy plates with high strength, corrosion resistance and good processing performance are usually selected. Among them, 5083 aluminum sheet is one of the commonly used marine aluminum plate models. It belongs to aluminum-magnesium alloy, has typical rust resistance, high strength and excellent processing performance. In addition, other aluminum plates such as 5052, 5086, 6061, 6082, etc. are also often used in the manufacture of ship keels.

Aluminum alloy models for keels:

5052 aluminum alloy: has good corrosion resistance and medium strength, suitable for lightweight components of ship structures.

5083 aluminum alloy: 5083 ship plate is a typical magnesium-aluminum-silicon alloy. High strength and excellent seawater corrosion resistance, very suitable for shipbuilding, especially in marine environments.

6061 aluminum alloy: heat treatable, with excellent mechanical properties and corrosion resistance, widely used in shipbuilding, especially suitable for structural parts.

6082 aluminum alloy: high strength, suitable for the frame and keel part of the hull.

Aluminum alloy ship keel processing technology:

The processing of aluminum alloy ship keels usually includes the steps of preparing aluminum alloy ingots, homogenization, extrusion molding, stretching and stabilization, cutting and installation. Through these process steps, aluminum alloy ship keels with excellent performance can be obtained.

Advantages of aluminum plates for ship keels:

1. Lightweight and high strength: The density of aluminum alloy is much lower than that of steel, but its strength is relatively high. Using aluminum alloy keels can significantly reduce the weight of the hull, improve the sailing speed and fuel economy.

2. Corrosion resistance: A dense aluminum oxide film is easily formed on the surface of aluminum alloy, which has good corrosion resistance. In the marine environment, aluminum alloy keels can effectively resist seawater erosion and marine biological attachment.

3. Good processing performance: Aluminum alloy is easy to cut, stamp, cold bend, form and cut in various forms of processing, suitable for streamlined design and manufacturing of the hull.

4. Good welding performance: Aluminum alloy has excellent welding performance, and welding operations can be carried out more easily to ensure that the connection of the keel is firm and reliable.

5. High safety: Aluminum alloy keels have a small elastic modulus and a large ability to absorb impact stress, which helps to improve the safety of ships. In the event of accidents such as collisions or reefs, it can reduce the degree of damage to the hull and personnel.

MC Aluminum is a large aluminum sheet/aluminum profile manufacturer with a complete range of product models that can be customized according to customer needs. Common marine aluminum plate models include: 5083 aluminum plate, 5086 aluminum plate, 5754 aluminum plate, 5052 aluminum plate and other products. They have passed a number of relevant certifications and have been successfully exported to more than 30 countries and regions. They are mainly used in ship decks, engine pedestals, ship sides, bottom outer plates and other components.

We will reply you in 24 hours.

info

Send Email

Wechat / Whatsapp

Trusted Aluminum Sheet Plate/Coil/Color Aluminium/Solid Aluminum Panel Manufacturers and Suppliers

5059 aluminum sheet is a 5 series aluminum-magnesium alloy aluminum sheet that is made stronger by strain hardening or cold machining. It is usually assembled using arc welding, usually MIG (for marine use) or TIG welding. 5059 aluminum alloy has good cor

More

Marine grade aluminum alloy sheet has strong resistance to corrosion by seawater and industrial chemicals, and is very suitable for welding. Due to its excellent corrosion resistance and weldability, coupled with high strength, 5086 marine grade aluminum

More

6082 aluminum sheet belongs to the 6××× series (Al-Mg-Si) alloy aluminum sheet. It is an aluminum alloy sheet that can be heat-treated and strengthened. It has medium strength, good welding performance and corrosion resistance. It is mainly used in transp

MoreSkype