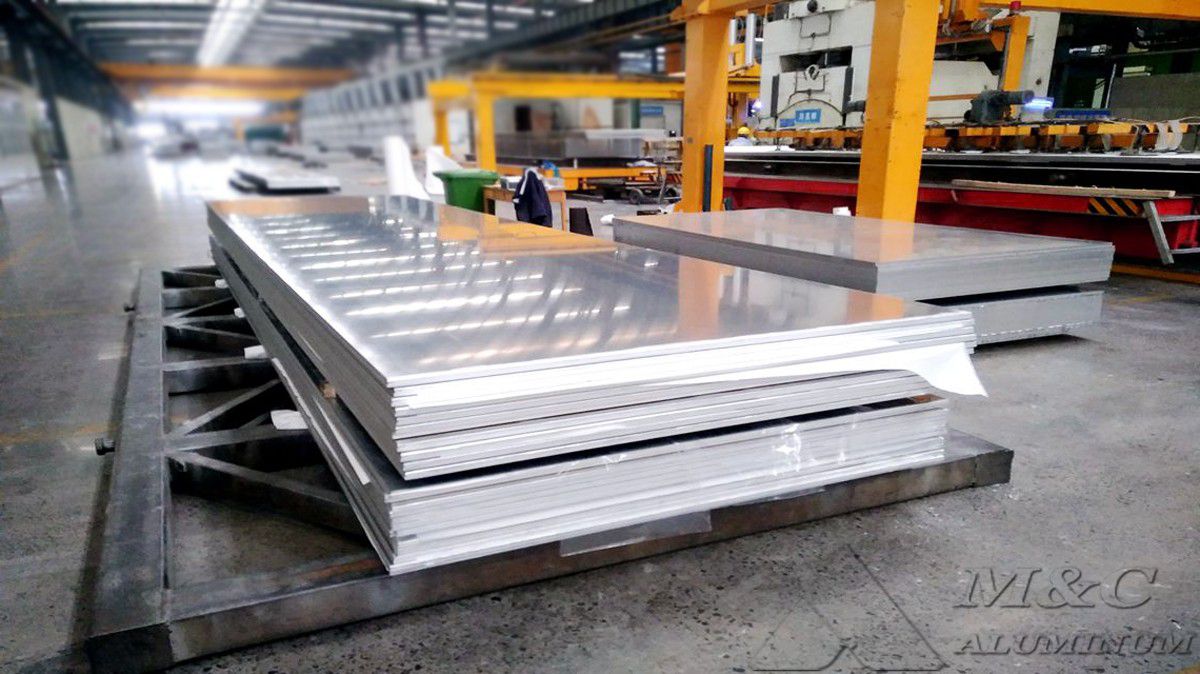

5383 aluminum alloy is an improved alloy of 5083 aluminum alloy. Compared with 5083 aluminum alloy, 5383 aluminum alloy has higher strength and better welding performance, which can optimize shipbuilding productivity and ship performance. The hardness of 5083 aluminum sheet has also increased by 10%. These potential performance improvements reduce the number of welded ships. The yield point of the welded structure has increased by 15%. With the characteristics of plasticity, weldability and yield, 5383 and 5083 aluminum sheets are favored by large high-speed ship manufacturers.

Specification

5083 Aluminum Plate Specifications:

| Temper | O, H111, H116, H112, H321 |

| Thickness | 3-50mm |

| Width | 20-2560mm |

| Length | 100-16000mm (6000/8000/9000/12000 or customized) |

| Delivery time | within 30 days |

| Productivity | 2000MT/month |

| Application | for high-speed ships, decks, hulls. |

5383 Chemical Element Content (%)

| Components | Fe | Si | Mn | Cr | Cu | Ti | Zr | Zn | Mg | Al | Other single |

| Min | - | - | 0.7 | - | - | - | - | - | 4 | 91.95 | - |

| Max | 0.2 | 0.25 | 1 | 0.25 | 0.2 | 0.15 | 0.2 | 0.4 | 5.2 | 95.3 | 0.05 |

5383 Mechanical Properties:

| Alloy | Temper | Thickness (mm) | Elongation strength Rp0.2 (N/mm2 | Tensile strength Rm (N/mm2) | Minimum elongation after break A① (%) | |

| 50mm | 5d | |||||

| 5383 | O | 3≤t≤50 | ≥145 | ≥290 | - | 17 |

H111 | 3≤t≤50 | ≥145 | ≥290 | - | 17 | |

| H116 | 3≤t≤50 | ≥220 | ≥350 | 10 | 10 | |

| H321 | 3≤t≤50 | ≥220 | ≥350 | 10 | 10 | |

Advantages

5383 aluminum sheet performance advantages:

1.Strong corrosion resistance: Particularly suitable for use in marine environments, such as ships and offshore platforms.

2.Excellent weldability: The performance remains good after welding, suitable for shipbuilding and building structures.

3.High strength and light weight: The strength-to-weight ratio is good, suitable for applications requiring lightweight materials.

4.Good ductility and formability: Easy to cold form, suitable for a variety of manufacturing processes.

5.No heat treatment required: The performance is stable after welding and processing, and no further heat treatment is required.

Application

Key points of marine 5083 aluminum alloy application

1. Hull structure:

Applicable to hulls, bottom plates and outer shells due to their light weight and corrosion resistance.

Ideal material for yachts, cargo ships, ferries, fishing boats, etc.

2. Offshore platforms and pontoons:

Widely used in offshore platforms and pontoons, long-term resistance to seawater corrosion, low maintenance cost.

3. Ship deck and internal structure:

Used for deck support, cabin partitions, control consoles, etc., with a high strength-to-weight ratio.

4. Marine transport containers:

Manufacturing storage tanks and liquid transport equipment, suitable for the storage and transportation of liquefied gases, chemicals and fuels.

5. Ship guardrails and gangways:

High strength and corrosion resistance, suitable for external structures such as guardrails and gangways to ensure safety and stability.

6. High-speed boats and yachts:

Lightweight and high-strength characteristics make it suitable for fast-moving ships, improving fuel efficiency and speed.

7. Submersibles and underwater equipment:

Manufacturing submersibles and underwater equipment, resistant to seawater erosion, maintaining high strength and pressure resistance.