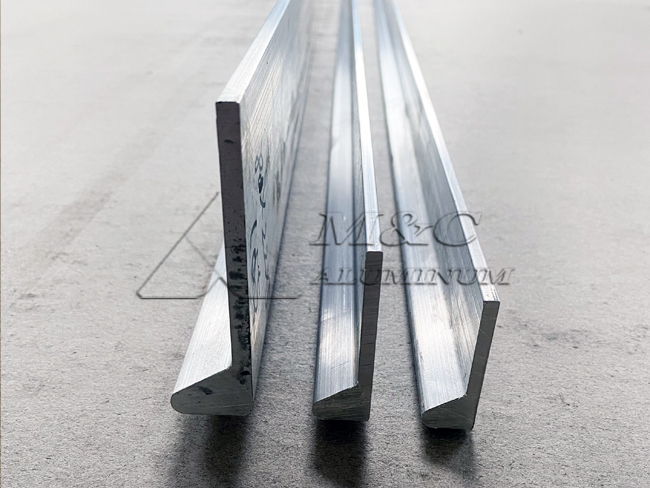

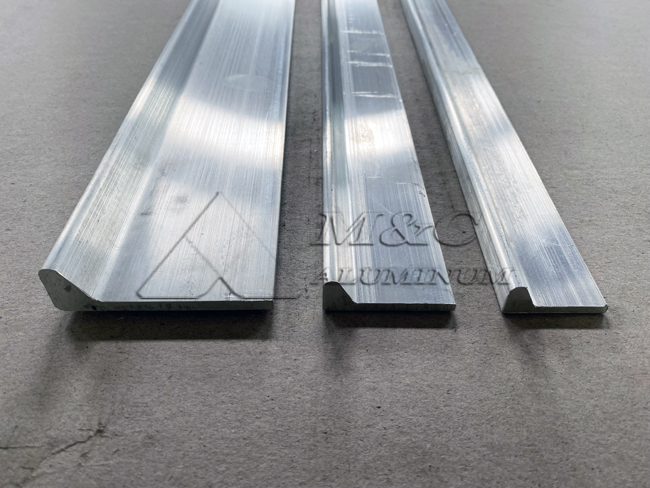

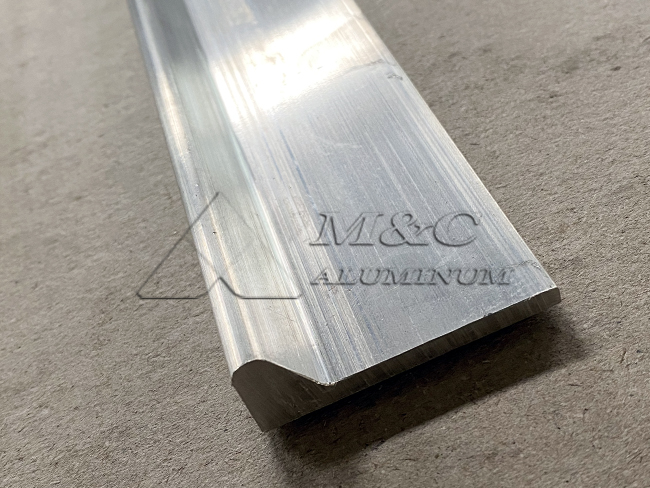

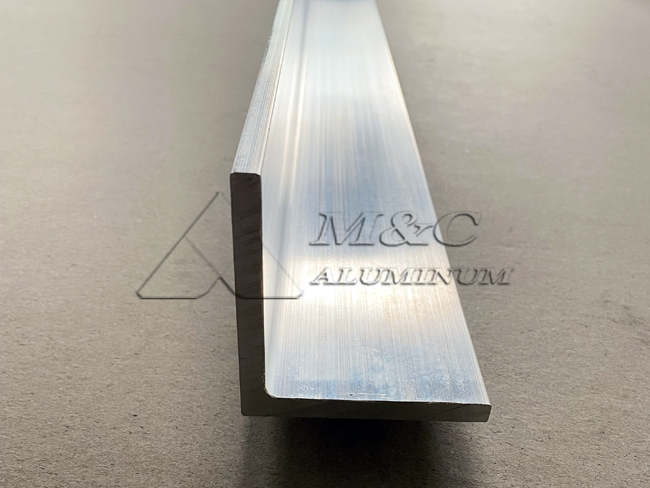

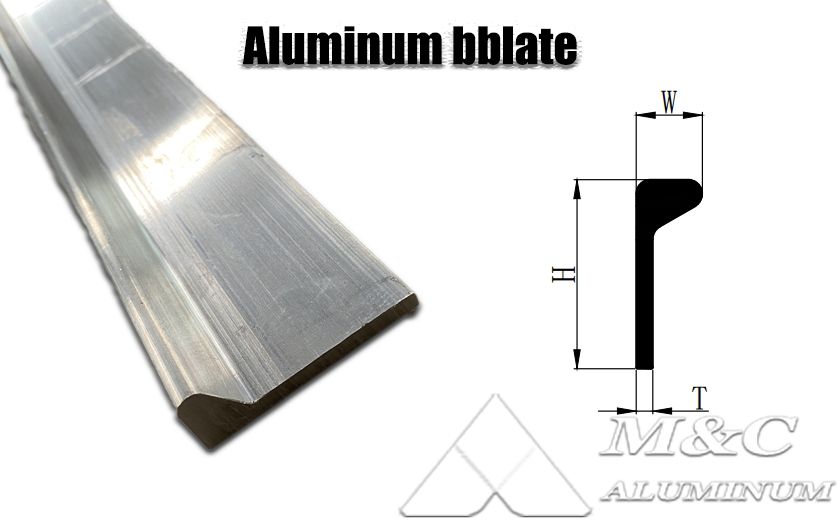

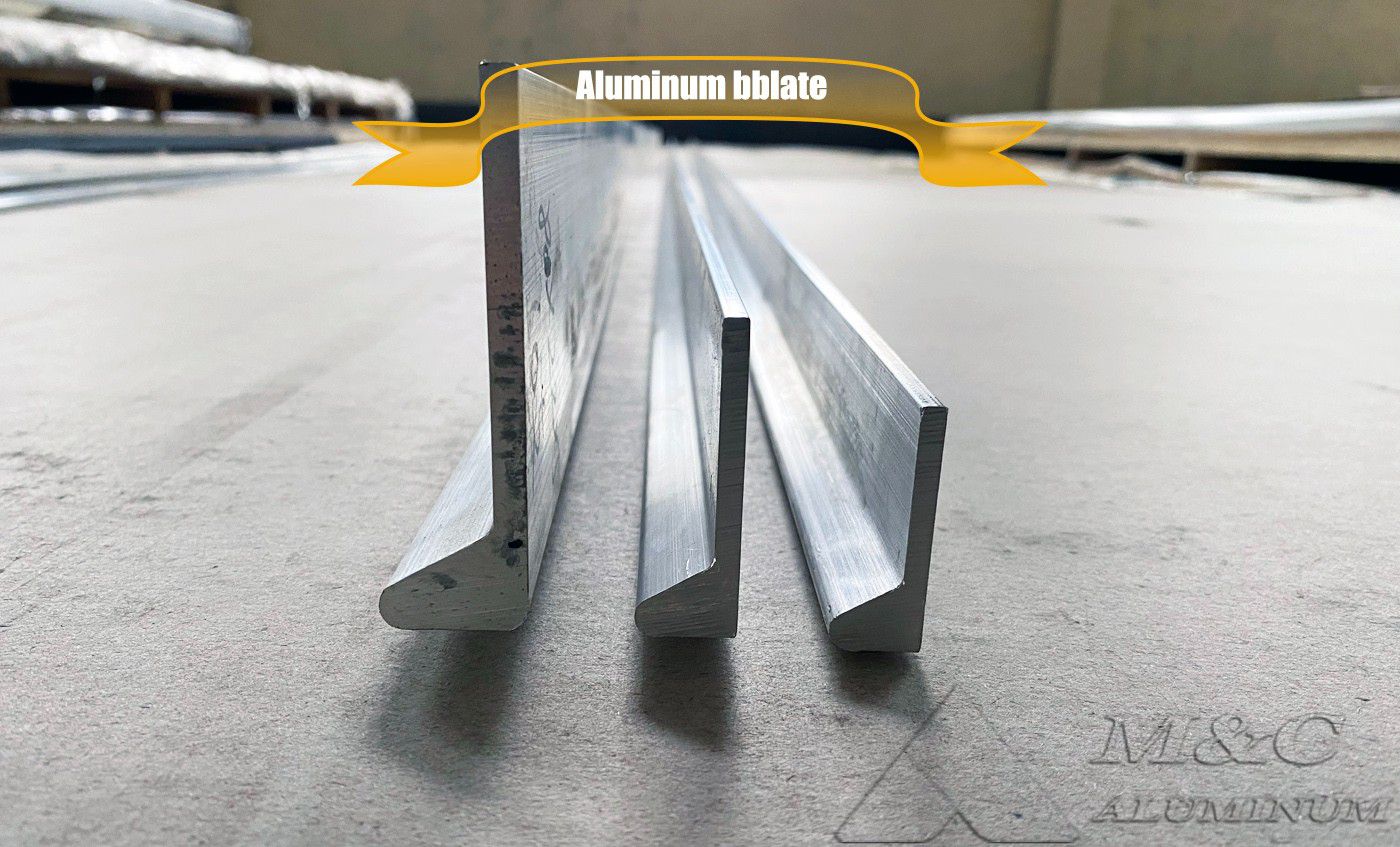

As a specific aluminum profile, aluminum bblate is an aluminum material with a specific cross-sectional shape. Its cross-section is usually flat with a rounded (or "spherical") edge. This shape design helps to enhance its structural strength and stability.

Common alloys of aluminum bblate include 5083 aluminum alloy, 5086 aluminum alloy, 6061 aluminum alloy, 5456 aluminum alloy, etc. It is an essential raw material for shipbuilding, bridges and some marine engineering. Marine aluminum bblate is a special profile for the shipbuilding industry. It is used as a ship hull reinforcement rib and plays an important role in the ship's carrying capacity and safe navigation ability.

Specifications

Specifications of aluminum bblate:

Aluminum bblat | ||

H (mm) | W (mm) | T (mm) |

40 | 4 | 3.5 |

| 50 | 16 | 3.5 |

| 60 | 15 | 3 |

| 80 | 22 | 5 |

| 90 | 18.75 | 4.2 |

| 100 | 21 | 6 |

| 105 | 18.75 | 4 |

| 120 | 7 | |

| 140 | 7 | |

| 160 | 7 | |

Specifications of marine aluminum bblate:

| Alloy | 5083, 5086, 5383, 5059, 6061, 6082, 6005A |

| Temper | H111/H112, T5/T6 |

| Certification | BV /DNV /ABS/Lioyds |

| Thickness | 3-50 mm |

Production process

Extrusion production process of aluminum bblate:

The production of aluminum bblate usually adopts the extrusion process, that is, the molten aluminum liquid is extruded into the required cross-sectional shape through a specific die. During the extrusion process, parameters such as temperature, pressure and speed need to be strictly controlled to ensure the quality and performance of the product.

1. Surface pretreatment: Use chemical or physical methods to clean the surface of the profile to expose the pure matrix so as to form a complete and dense oxide film. Mirror or matte effects can be achieved mechanically.

2. Anodizing: Under specific process conditions, the pretreated profile surface is anodized to generate a dense, porous and highly adsorbable Al2O3 film layer.

3. Sealing: Seal the pores of the film after anodizing to enhance the anti-pollution, corrosion resistance and wear resistance of the oxide film. The oxide film is transparent and can achieve a variety of colors such as black, bronze, golden, etc. by adsorbing metal salts.

Advantages

Features and advantages of marine aluminum bblate:

1. Light weight: Reduce the weight of the hull relative to steel, improve load and fuel efficiency.

2. Corrosion resistance: Can resist salt water corrosion in the marine environment and extend service life.

3. High strength: Although light, it has high strength to meet the structural requirements of the ship.

4. Good machinability: Easy to weld, cut, bend, etc., adapt to complex designs.

5. Recyclability: High recycling value, environmentally friendly, reducing the impact of manufacturing and scrapping on the environment.

Application

Application areas of aluminum bblate:

1. Shipbuilding: aluminum bblate is widely used in key parts such as decks, hull structures, bulkheads, etc. of ships. Its high strength and corrosion resistance ensure the safe operation of ships in harsh marine environments.

2. Marine engineering: aluminum bblate also plays an important role in marine engineering such as offshore platforms and submarine pipelines. It can withstand the corrosion of seawater and the attachment of marine organisms while maintaining the stability and safety of the structure.

3. Other fields: In addition to shipbuilding and marine engineering, bulb-aluminum bblate may also be used in other fields that require high-strength and corrosion-resistant materials, such as bridge construction, chemical equipment, power facilities, etc.