5059 aluminum sheet is a 5 series aluminum-magnesium alloy aluminum sheet that is made stronger by strain hardening or cold machining. It is usually assembled using arc welding, usually MIG (for marine use) or TIG welding. 5059 aluminum alloy has good corrosion resistance and tensile strength. It is a 5 series product with excellent comprehensive performance and is widely used in ships, tankers and other fields.

In marine environments and other corrosive environments, 5059 aluminum alloy exhibits excellent corrosion resistance, which makes it an ideal material for marine structures and shipbuilding. It has been used as a hull material for small aluminum boats or large yachts. 5059 aluminum alloy has obtained China Classification Society (CCS) certification.

The new generation of marine engineering deformed aluminum alloy 5059 aluminum alloy contains higher Si, Fe, Mn and Mg, as well as trace amounts of Zn and Zr elements compared to traditional 5083 aluminum alloy. The performance of 5059 alloy is better than that of 5083 alloy, but the pressure processing and forming performance are slightly inferior.

Specifications

5059 marine aluminum plate specifications:

| Temper | O, H111, H116, H321 |

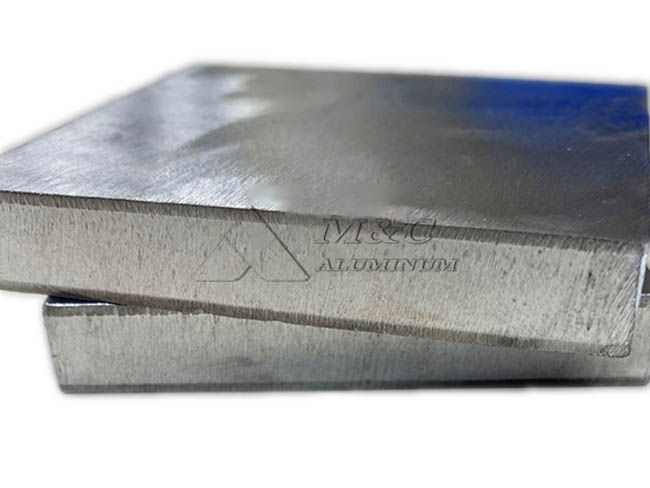

| Thickness | 3-50mm |

| Width | 100-2650mm |

| Length | 100-16000mm |

| Certificate | DNV、NK、CCS、ABS、BV、LR |

Mechanical properties of 5059 marine grade aluminum sheet:

Alloy | Temper | Thickness (mm) | Tensile Strength RmMPa | Specified non-proportional tensile strength Rp0.2 Mpa | Specified non-proportional tensile strength Rp0.2 Mpa | |

A50 mm | A | |||||

| 5059 | O | 3.00-50.00 | 330-380 | ≥160 | ≥24 | ≥24 |

H111 | 3.00-50.00 | 330-380 | ≥24 | ≥24 | ≥24 | |

H116 | 3.00-20.00 | ≥370 | ≥270 | ≥10 | ≥10 | |

>20.00-50.00 | ≥360 | ≥260 | - | ≥10 | ||

H321 | 3.00-20.00 | ≥370 | ≥270 | ≥10 | ≥10 | |

20.00-50.00 | ≥360 | ≥260 | - | ≥10 | ||

Anti-corrosion peeling performance | plate sheets in the state of H116 and H321 shall not have Class E exfoliation corrosion after exfoliation corrosion test; when the contract is marked as "used for sea-going hull shell" or "long-term direct contact with seawater", PB shall not appear after exfoliation corrosion test Exfoliation corrosion. Exfoliation corrosion resistance test shall be carried out according to the method specified in GB/T 22639. | |||||

Intergranular corrosion performance | For plate sheets in the state of H116 and H321, the maximum depth of intergranular corrosion does not exceed grade 3 after the intergranular corrosion test. Carry out intergranular pitting corrosion test according to the method specified in GB/T 7998. | |||||

Chemical composition of 5059 aluminum alloy:

Grade | Max(%) | ||||||||

Alloy 5059 | Si | Fe | Cu | Mn | Mn | Cr | Zn | Ti | Al |

0.45 | 0.5 | 0.25 | 0.6-1.2 | 5.0-6.0 | 0.25 | 0.40-0.9 | 0.2 | Remainder | |

Production process

5059 Aluminum sheet production process:

1. Casting

Continuous casting: used to produce sheets and strips, high-quality billets can be obtained through continuous casting process.

Semi-continuous casting: suitable for the production of thicker sheets and bars to ensure the uniformity and consistency of the material.

2. Heat treatment

Annealing: Annealing at 345°C to 370°C can soften the material, eliminate work hardening, and improve the plasticity of the material.

Stress relief treatment: Stress relief treatment at 260°C to 345°C can reduce residual stress and improve the dimensional stability of the material.

3. Cold working

Cold rolling: 5059 aluminum alloy can be produced into thin sheets and strips through cold rolling process. The cold-rolled material has good surface quality and high strength.

Stretching: The strength and hardness of the material can be improved through the stretching process during cold working, which is suitable for the manufacture of high-strength structural parts.

4. Welding

TIG welding: tungsten inert gas shielded welding, suitable for thinner sheets, high welding quality and beautiful welds.

MIG welding: Molten inert gas shielded welding, suitable for thicker sheets, high welding efficiency, suitable for large-scale production.

Resistance welding: Suitable for welding thin sheets and pipes, fast welding speed, suitable for automated production.

5. Machining

Cutting: 5059 aluminum alloy can be cut by shearing, sawing and laser cutting, and the edge is smooth after processing.

Drilling and tapping: 5059 aluminum alloy has good cutting performance and is suitable for machining operations such as drilling and tapping.

Turning and milling: Suitable for manufacturing parts with complex shapes. During the processing, attention should be paid to using appropriate coolant to prevent overheating of the material.

6. Surface treatment

Anodizing: Anodizing can improve the surface hardness and corrosion resistance of 5059 aluminum alloy, while increasing its aesthetics.

Coating treatment: Anti-corrosion coating can be sprayed or brushed on the surface to further enhance the corrosion resistance of the material, suitable for marine environment.

7. Forming

Stamping and bending: 5059 aluminum alloy has good formability, and various parts with complex shapes can be manufactured by stamping and bending processes.

Extrusion: Suitable for producing products with complex cross-sections such as pipes and profiles, and the materials have high dimensional accuracy and surface quality.

Advantages

5059 marine aluminum plate performance advantages:

1. Small specific gravity, can reduce the weight of the ship, save energy consumption, and increase the load capacity;

2. Good corrosion resistance, extending the service life;

3. Good welding and processing performance, conducive to later processing;

4. Non-flammable, safe in case of fire;

5. Environmentally friendly materials, can be recycled.

Application

5059 marine aluminum plate is suitable for manufacturing ship hulls, cabin sidings, decks, marine pipes and other parts. In addition, it can also be used to manufacture marine engineering structures such as offshore platforms and offshore oil drilling platforms. Its low density, high strength, high rigidity and corrosion resistance are very suitable for the material selection requirements of the shipbuilding industry, and it is more economical to use aluminum to manufacture ships.

Choss US

Why choose MC Aluminum for 5059 Aluminum Plate?

1. We offer the best price for 5059 alloy aluminum plate, ensuring global delivery in the shortest possible time.

2. We offer various types of 5059 aluminum, each with unique specifications. Whether you need different thickness, width or tempering options, we can customize to meet your specific requirements.

3. Classification society certificates are available: ABS, BV, CCS, DNV, KR, LR, RINA, etc.

4. We cater to global markets, including Africa, America, Asia, Europe, EU and Middle East.