Introduction

An aluminum reducer is a type of pipe fitting used to connect pipes of different diameters. These reducers are commonly made from aluminum due to its lightweight properties, corrosion resistance, and cost-effectiveness.

Types

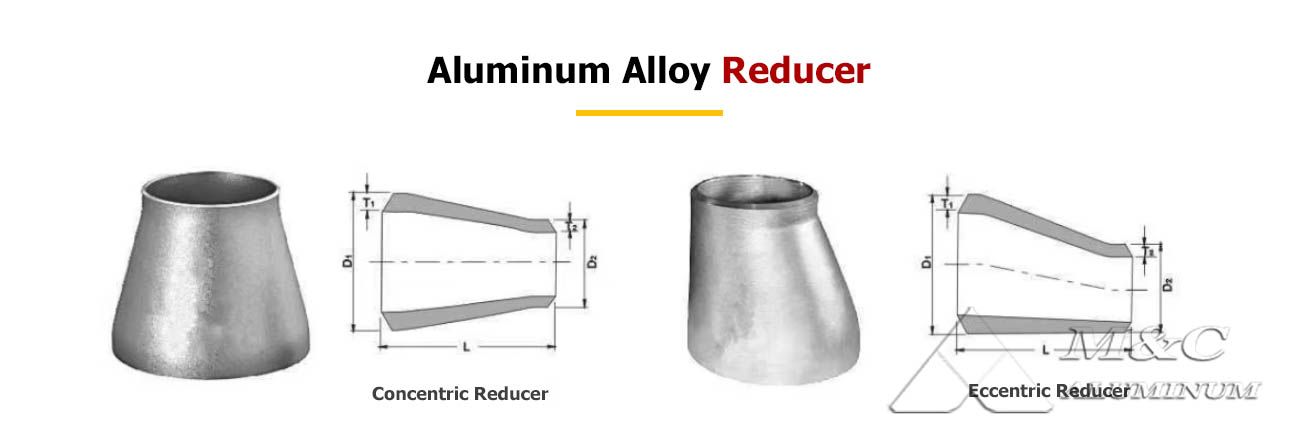

Types of Aluminum Alloy Reducers

1.Concentric Reducer (Aluminum Weld Concentric Reducer) – The centers of both ends are aligned on the same axis, typically used in vertical piping systems to ensure smooth fluid flow.

2.Eccentric Reducer – The centers of both ends are not aligned, making it suitable for horizontal piping to prevent gas or liquid accumulation.

Material

Common Aluminum Alloys for Reducers

Aluminum reducers are available in various alloys, including 6063, 6061, 6082, 5052, 5083, 5086, and 7075, each offering unique benefits:

7075 : Extremely high strength and wear resistance, used in aerospace and military equipment.

6061 : High strength and corrosion resistance, widely used in industrial and construction applications.

6063 : Excellent extrusion properties and surface finish, commonly used in architectural and decorative applications.

5052 : Superior corrosion resistance, ideal for marine environments and chemical processing.

5083 : Exceptional corrosion resistance, suitable for harsh environments such as marine, chemical, and food processing pipelines.

3003 : Moderate strength and good corrosion resistance, commonly used for general industrial applications.

Specifications

| Type | Eccentric; Concentric |

| Diameter Range | DN15-DN1000 (1/2” – 40”) |

| Thickness Range | Sch5 - Sch160 |

| Length | Standard: 100mm-300mm (Customizable) |

| Material | Aluminum Alloy |

| Available Alloys | 6063, 6061, 6082, 5052, 5083, 5086, 7075 |

| Surface Treatment | Anodizing, Sandblasting, Polishing |

| Connection Type | Welding |

| Bend Degree | 30°, 45°, 90°, 180°, 1.0D - 40D |

| Standards | GB (Chinese), ASTM (American), JIS (Japanese), EN (European) |

Features

Key Features of Aluminum Reducers

1.Lightweight : Lighter than stainless steel and carbon steel, reducing transportation and installation costs.

2.Corrosion Resistance : Oxidation-resistant and rust-free, suitable for various chemical environments.

3.Good Thermal Conductivity : Ideal for high-heat transfer applications such as heat exchangers.

4.Moderate Strength : Provides good pressure resistance, meeting different working conditions.

5.Excellent Weldability : Easy to weld and process, suitable for complex piping systems.

6.Aesthetic & Durable : Smooth surface with modern appearance, resistant to rust and long-lasting.

7.Eco-Friendly & Recyclable : 100% recyclable, aligning with environmental standards.

Applications

1.Plumbing Systems – Used to connect water pipes of different sizes for smooth water flow transitions.

2.Air Conditioning & Refrigeration – Connects pipes of different diameters in cooling and refrigeration systems to regulate refrigerant flow.

3.Industrial Pipelines – Essential for connecting pipelines of various diameters in industrial processing.

4.Automotive Manufacturing – Used in exhaust systems, cooling systems, and fuel supply systems where diameter variations are required.

5.Aerospace Industry – Applied in aircraft hydraulic, fuel, and pneumatic systems due to its lightweight and high-strength properties.

6.Chemical Industry – Used in chemical transportation pipelines due to its excellent corrosion resistance.

7.Power Industry – Found in boilers, steam turbines, and cooling systems for fluid and gas transmission.