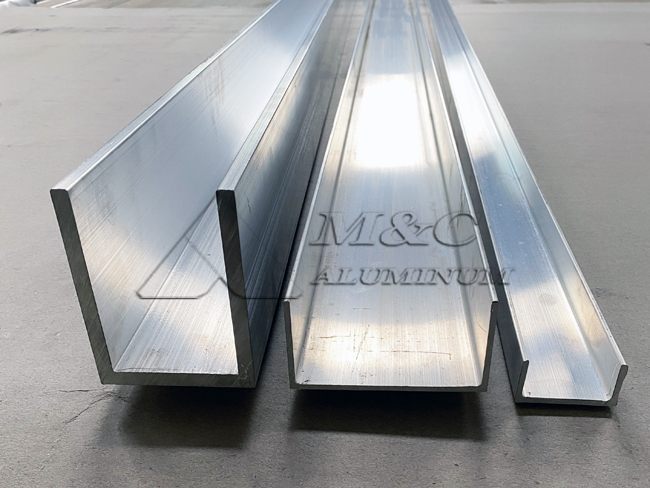

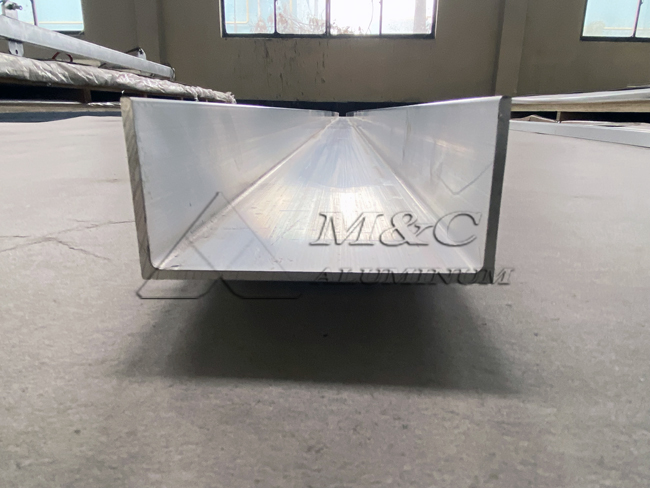

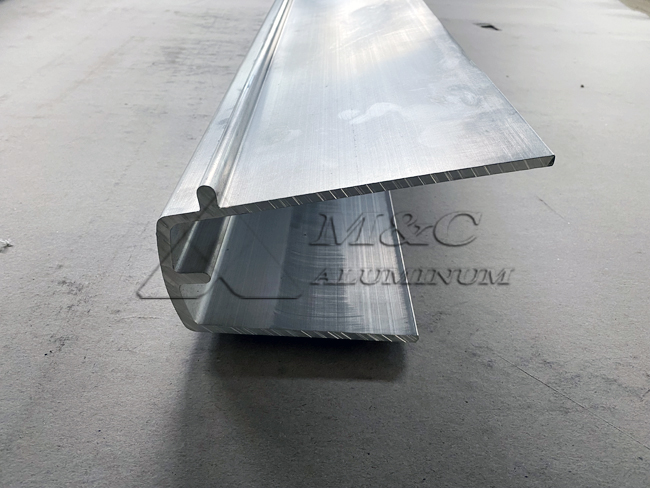

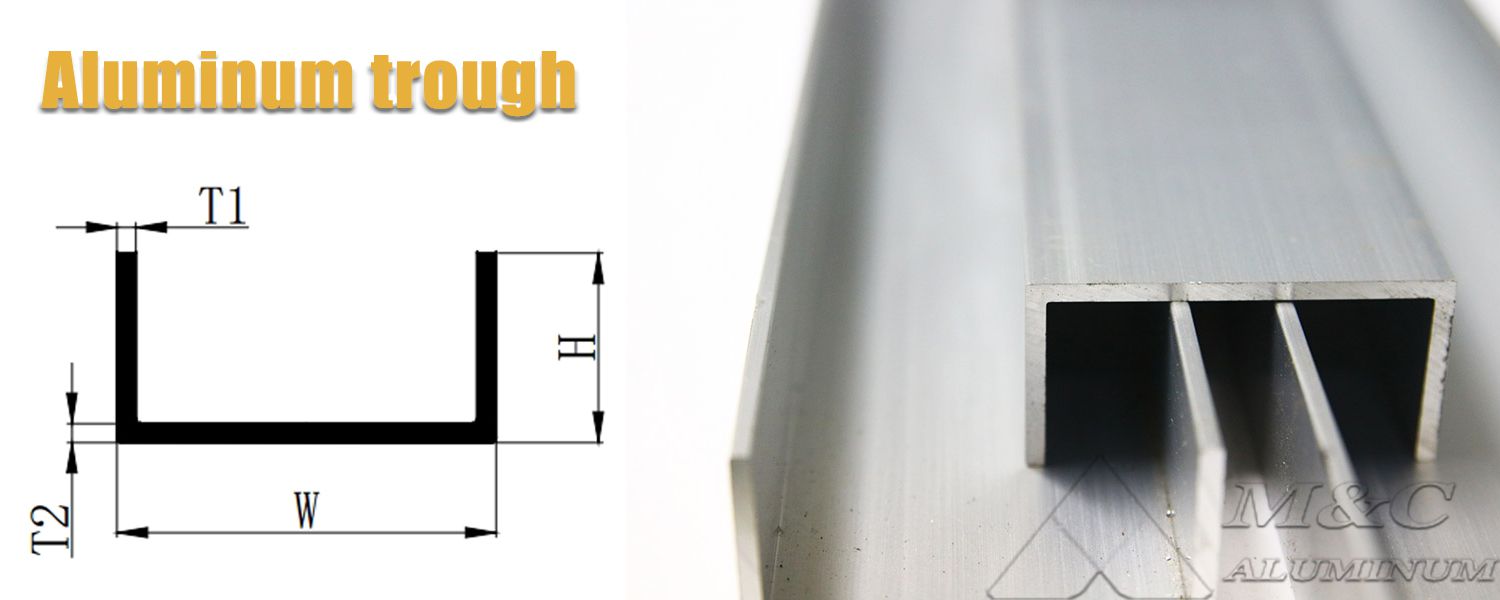

Aluminum trough is a channel-shaped aluminum profile, also known as U-Aluminum trough and C-Aluminum trough. It is widely used in construction, machinery manufacturing, shipbuilding, automotive industry, furniture and other fields. The channel structure of Aluminum trough gives it good bending strength and rigidity when subjected to external forces. At the same time, due to the lightness, corrosion resistance and easy processing of aluminum, it has become an ideal choice for various projects and products.

Specification

Aluminum trough specification parameters:

| Aluminum trough | |||

| W1 (mm) | H (mm) | T1 (mm) | T2 (mm) |

| 25 | 25 | 3 | 3 |

| 50 | 25 | 3 | 3 |

| 50 | 40 | 4 | 4 |

| 50 | 50 | 5 | 5 |

| 80 | 100 | 8 | 8 |

| 100 | 25 | 3 | 3 |

| 100 | 50 | 3 | 3 |

| 100 | 50 | 5 | 5 |

| 152.4 | 76.2 | 9.5 | 6.4 |

| 203.2 | 76.2 | 12.7 | 9.5 |

Marine aluminum channel specifications:

| Alloy | 5083, 5086, 5383, 5059, 6061, 6082, 6005A,etc |

| Temper | H111/H112, T5/T6 |

| Certification | CCS,BVLR,ABS,DNV-GL |

| Thickness | 3-50 mm |

| Marine Aluminum T Bar Aluminum Alloys Composition | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | Other | Al | |

| Each | Total | ||||||||||||

| 5083 | 0.40 | 0.40 | 0.1 | 0.4-1.0 | 40.-4.9 | 0.05-0.25 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 5383 | 0.25 | 0.25 | 0.20 | 0.7-1.0 | 4.0-5.2 | 0.25 | - | 0.40 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 5086 | 0.40 | 0.50 | 0.1 | 0.2-0.7 | 3.5-4.5 | 0.05-0.25 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 5059 | 0.45 | 0.05 | 0.25 | 0.6-1.2 | 5.0-6.0 | 0.25 | - | 0.4-0.9 | 0.20 | - | 0.05 | 0.15 | Remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

| 6005A | 0.5-0.9 | 0.35 | 0.3 | 0.5 | 0.4-0.7 | 0.3 | - | 0.2 | 0.1 | - | 0.05 | 0.15 | Remainder |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.25 | - | 0.2 | 0.1 | - | 0.05 | 0.15 | Remainder |

| Mechanical Properties of Marine Aluminum T Bar | |||||||

Alloy | Form | Thickness(mm) | Temper | Rm | Rp0.2 | A% Min | |

Min. | Aso | Aso | |||||

5086 | Shapes, Bar, Tube | 3≤t≤50 | H112 | 240 | 95 | 10 | 12 |

| 5083 | Shapes, Bar, Tube Shapes, Bar, Tube | 3≤t≤50 | H111 | 270 270 | 110 125 | 10 10 | 12 12 |

| 5059 | Shapes, Bar, Tube | 3≤t≤50 | H112 | 330 | 200 | 10 | |

5383 | Shapes, Bar, Tub | 3≤t≤50 | O | 290 | 145 | 17 | 17 |

Shapes, Bar, Tub | 3≤t≤50 | H112 | 310 | 190 | 13 | ||

6061 | Shapes, Bar, Tube Profiles | 3≤t≤50 3≤t≤50 | T5 or T6 | 260 245 | 240 205 | 10 | 8 4 |

| 6005A | Shapes, Bar, Tube Profiles | 3≤t≤50 | T5 | 260 | 215 | 9 | 8 |

Shapes, Bar, Tube Profiles | 3≤t≤10 | T6 | 260 | 215 | 8 | 6 | |

3≤t≤10 | 250 | 200 | 8 | 6 | |||

6082 | Shapes, Bar, Tube Closed shapes | 3≤t≤50 3≤t≤50 | T5 or T6 | 310 290 | 260 240 | 10 | 8 5 |

Advantages

Summary of advantages of marine aluminum trough:

1. Low density and light weight: The density is only one-third that of steel, which significantly reduces the overall weight of the ship and helps improve navigation speed and fuel economy.

2. High strength: After special processing and heat treatment, it has high strength, can withstand the challenges of the marine environment, and ensures structural stability and safety.

3. Corrosion resistance: An aluminum oxide film naturally forms on the surface, effectively preventing seawater erosion, extending service life and reducing maintenance costs.

4. Good processability: easy to cut, stamp, cold bend, etc., suitable for streamlined design and manufacturing.

5. Non-combustible: Excellent fire resistance, it will not burn even in high temperature environments, improving ship safety.

Application

Application fields of marine aluminum trough:

1. Hull structure: It can be used for hull frame, deck support, cabin separation, etc. to enhance the overall rigidity and stability of the ship.

2. Outfitting equipment: During the outfitting process, it can be used to make equipment brackets, pipe brackets and cable trays to meet the installation and fixing needs of the ship's internal equipment.

Choose US

1. We have passed China ISO9001 certification.

2. Provide CCS, BVLR, ABS, DNV-GL and other certificates.

3. The company currently has more than 500 sets of profile molds and more than 300 specifications of profiles in stock.

4. Provide customized production services.