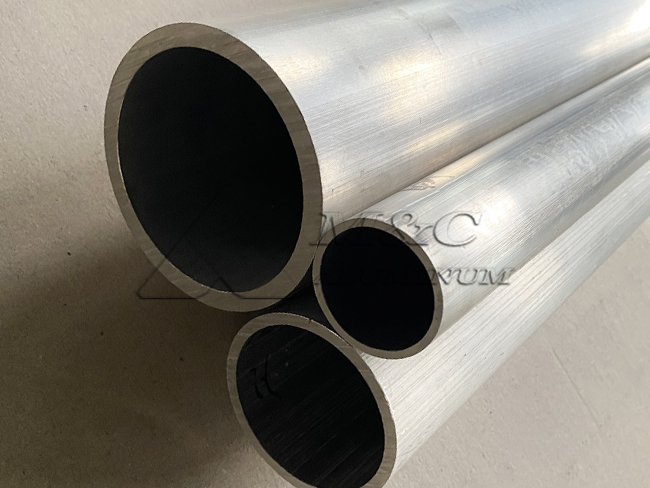

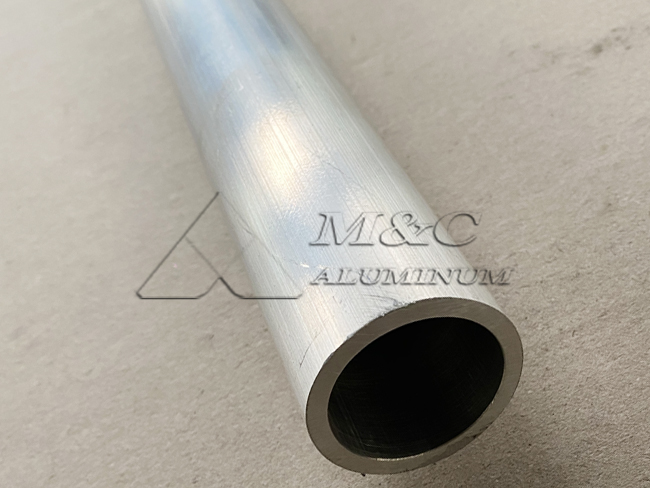

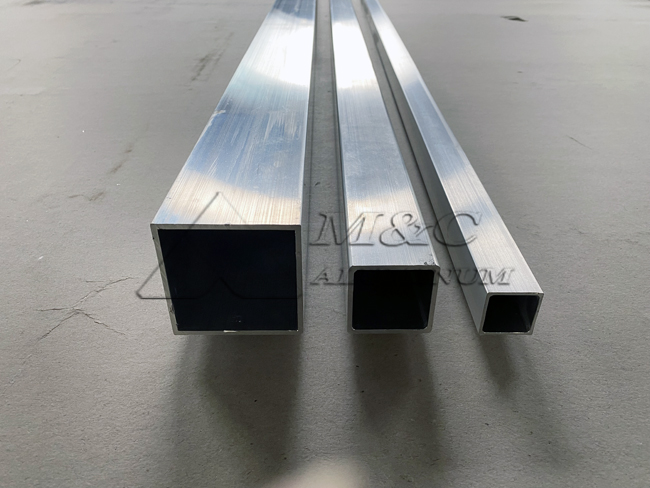

Aluminum tube for shipbuilding refers to a metal tubular material that is made of pure aluminum or aluminum alloy through extrusion and is hollow along its entire longitudinal length. According to different alloy components and processing methods, aluminum tubes can be divided into many types, such as 6061 aluminum tube, 6063 aluminum tube, 5083 aluminum tube, etc. Mainly used for structural parts, piping systems and other accessories in shipbuilding.

Aluminum tube production process:

Heating billets, extrusion, profile quenching, solution treatment, straightening, furnace aging.

Specification

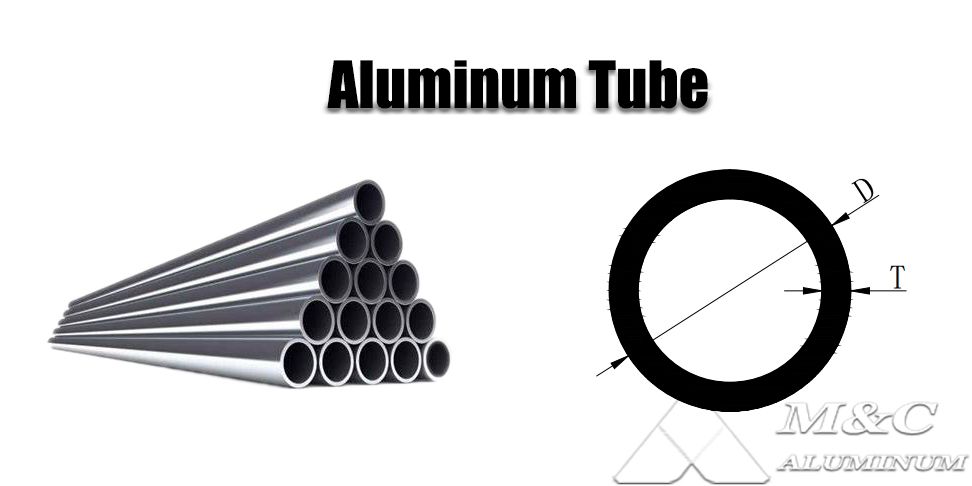

Aluminum tube parameters:

Aluminum Tube | |

D (mm) | T (mm) |

| 22 | 3 |

| 35 | 5 |

| 45 | 4 |

| 50 | 4 |

| 60 | 3 |

| 70 | 6 |

| 80 | 5 |

| 108 | 8 |

| 120 | 3 |

| 130 | 10 |

Marine aluminum round tube specifications:

| Alloy | 5083, 5086, 5383, 5059, 6061, 6082, 6005A |

| Temper | H111/H112, T5/T6 |

| Certification | BV /DNV /ABS/Lioyds |

| Thickness | 3mm---50mm |

Advantages

Features of aluminum tubes for ships:

1. Lightweight: Aluminum is light, which helps to reduce the total weight of the ship, improve fuel efficiency and navigation performance.

2. Corrosion resistance: Aluminum is corrosion-resistant in salt water and humid environments, suitable for long-term use at sea.

3. High strength: Although aluminum is light, it has high strength and can withstand the pressure and load in ship use.

4. Easy processing: Aluminum materials are easy to cut, weld and form, increasing the flexibility of ship manufacturing and maintenance.

5. Good thermal conductivity: Aluminum has good thermal conductivity and is suitable for piping systems for heat dissipation and temperature management.

Company Strength

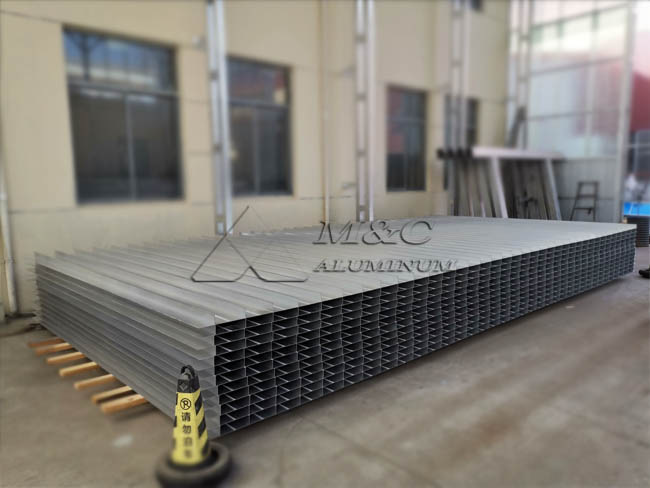

Why choose MC aluminum?

1. The product has passed ISO, CCS, BV, LR, DNV-GL and other certifications.

2. MC Aluminum currently has more than 500 sets of molds and more than 300 specifications of profiles in stock.

3. The company is equipped with 4 sets of automatic melting and casting furnaces, 10MN-125MN production lines, 125MN double-action extrusion production lines, 19-meter vertical quenching furnaces, 2,400-ton horizontal stretching machines, etc.