6061 is a precipitation hardening alloy, an aluminum alloy with magnesium and silicon as the main alloying elements. It can be heat treated and strengthened, has medium strength, its strength is close to that of 2 series alloys, and has good extrusion forging performance. This marine aluminum alloy has excellent weldability and good mechanical properties, and is one of the most commonly used general alloys. 6061 has more alloying elements than 6063, so the material strength is higher.

6061 aluminum sheet has the characteristics of good corrosion resistance, high toughness, no deformation after processing, easy coloring, and good oxidation effect. It can still maintain good operability after annealing.

Specification

6061 marine grade aluminum sheet specifications:

| Alloy | 6061 |

| Temper | O,T4,T6,T651 |

| Thickness | 3-50 mm |

| Width | ≤2650 mm |

| Length | 1000-16000 mm |

| Certifications | SGS, GL, ABS, CCS, BV, LR |

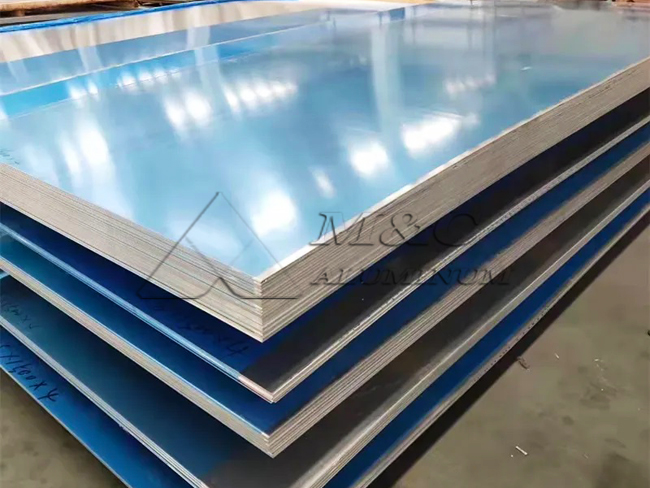

| Lamination types | Blue film, transparent film, black and white film, paper (film thickness: 50 microns, 80 microns) |

Chemical composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Zr |

| 6061 | 0.40-0.80 | 0.70 | 0.15-.040 | 0.15 | 0.80-1.20 | 0.04-0.35 | - | 0.25 | 0.15 |

Mechanical properties

| 6061-O | 6061-T4 | 6061-T451 | 6061-T6 | 6061-T651 | |

| Shear Strength | 84MPa | 170MPa | 170MPa | 210MPa | 210MPa |

| Tensile Strength | 76-130MPa | 130-230MPa | 130-240MPa | 270-310MPa | 270-320MPa |

| Elastic Modulus | 69GPa | 69GPa | 69GPa | 69GPa | 69GPa |

| Brinell Hardness | 33 HB | 63 HB | 63 HB | 93 HB | 93 HB |

| Elongation | 20% | 18% | 20% | 20% | 11% |

6061 Temper

6061 different tempering states:

AA6061 O aluminum plate: has good extrusion formability and has higher hardness and strength after quenching.

6061 T4 aluminum plate: after solution heat treatment and natural aging, the ductility is enhanced and it has higher formability compared with 6061 T6 plate.

6061 T6 aluminum plate: a very popular alloy, usually less than 1/4 inch thick. It has excellent corrosion resistance and can be further enhanced by protective coating treatment.

Al6061 T651 aluminum plate: developed from 6061-T6 by stretching to eliminate internal stress. It is the most common heat-treatable aluminum alloy and is more suitable for forming processes.

What is the difference between 6061 T4 and 6061 T6 aluminum plates?

1.Production process: 6061T4 uses solution heat treatment + natural aging, 6061T6 uses artificial aging.

2.Mechanical properties: 6061 T4 has higher elongation, which enhances its formability. 6061 T6 has higher tensile strength and yield strength, and is stronger than 6061 T4.

3.Surface treatment: 6061 T6 can be anodized.

4.Price: 6061T4 is relatively cheap, and 6061T6 costs slightly more.

Advantages

Features of 6061 aluminum plate for ships:

1.High strength: After T6 heat treatment, it has high strength and hardness, suitable for manufacturing pressure-bearing parts such as hulls and decks.

2.Corrosion resistance: It has good resistance to seawater and atmospheric corrosion, meeting the requirements of marine materials.

3.Lightweight: Low density, lighter than steel, helps to reduce hull weight and improve fuel efficiency.

4.Weldability: Easy to weld, especially suitable for common welding methods such as argon arc welding, which facilitates the assembly of ship structures.

5.Machinability: Easy to form, cut and process, with good processing performance.

Application

6061 aluminum sheet application:

◆ 6061 aluminum sheet is widely used on merchant ship decks, including cargo ships, fishing boats, yachts, etc. It is light and corrosion-resistant, which can improve the ship's carrying capacity, sailing speed and service life.

◆ Warships and marine engineering ships have high strength requirements and must withstand the test of complex marine environments and harsh climatic conditions. 6061 aluminum sheet can meet these requirements and provide a stable and safe platform.

◆ For cruisers and corvettes, comfort and appearance are also important considerations. 6061 aluminum sheet can easily create a flat and beautiful platform, bringing excellent experience and visual effects.

Surface quality

6061 aluminum sheet quality requirements:

1. The surface of the aluminum sheet is flat and clean, without scratches, black lines, peeling, inclusions, hot lines, gas paths, sticky rollers, holes, corrosion oxidation, yellow oil spots, etc.

2. The length, width, and thickness size tolerances meet customer requirements

Choose US

Why choose MC Aluminum?

1. All products have passed ISO 9001, GJB 9001, AS9100, TS16949 and other quality system certifications

2. The maximum width of aluminum sheets produced by MC Aluminum is 2650 mm, and the minimum thickness is 0.2 mm, which can meet various thickness and width requirements.

3. MC Aluminum has introduced a 1+4 4500mm hot rolling production line, with Siemens electrical equipment and a German IMS curvature meter to achieve closed-loop control of thickness and sheet shape.

4.The excellent product quality has enabled Haomei Aluminum to pass the following certifications: China Classification Society (CCS), American Bureau of Shipping (ABS), Bureau Veritas (BV), Lloyd's Register (LR), Kosher Certification (SKS), Korean Register (KR) and so on, and the product quality is guaranteed.