Ribbed panel, as the name implies, is a plate with reinforcing ribs. It is a commonly used type of aluminum alloy plate. It usually consists of a base plate and reinforcing ribs (or ribs) arranged along a certain direction. These reinforcing ribs are firmly combined with the base plate through certain processes (such as riveting or MIG welding, etc.) to form an integral structure. The advantage of the reinforcing ribs is that they can greatly improve the bending or buckling stiffness of these aluminum plates. FSW welding of reinforced plates is becoming more and more popular in high-tech industries. Friction stir welding technology can produce lighter and stronger reinforced plates.

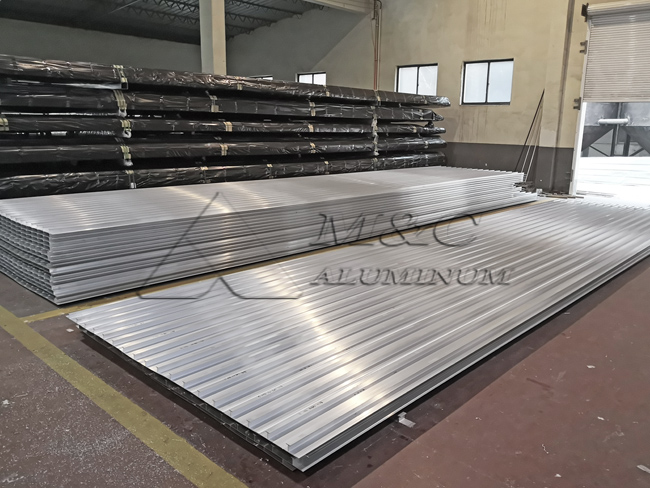

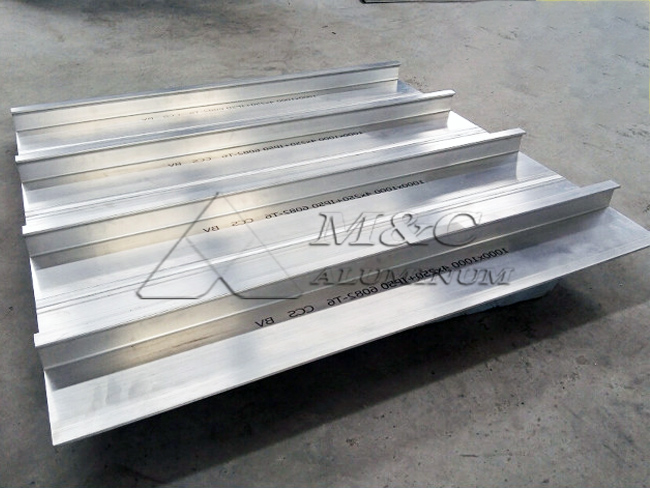

Marine grade ribbed aluminum plates can be divided into single stiffener panel, doublestiffener panel, and multi stiffener panel. They are made of 6082 aluminum alloy, tempered in T6 state, with a length of 6000mm and a width that depends on the extrusion die, generally within 2100mm. The longitudinal direction of the reinforced aluminum plate profile is generally longitudinal, and this longitudinal arrangement is suitable for the main hull and superstructure.

With the development of the shipping industry, aluminum alloy structures have been widely used in ship design and manufacturing. The aluminum alloy structure plate is thin and the ribs are densely arranged. In order to improve efficiency and reduce welding work, a ribbed plate structure is adopted. The beams, ribs, and longitudinal girders are directly installed on the ribbed plate and connected by connectors. A hanging and riding rib structure is adopted.

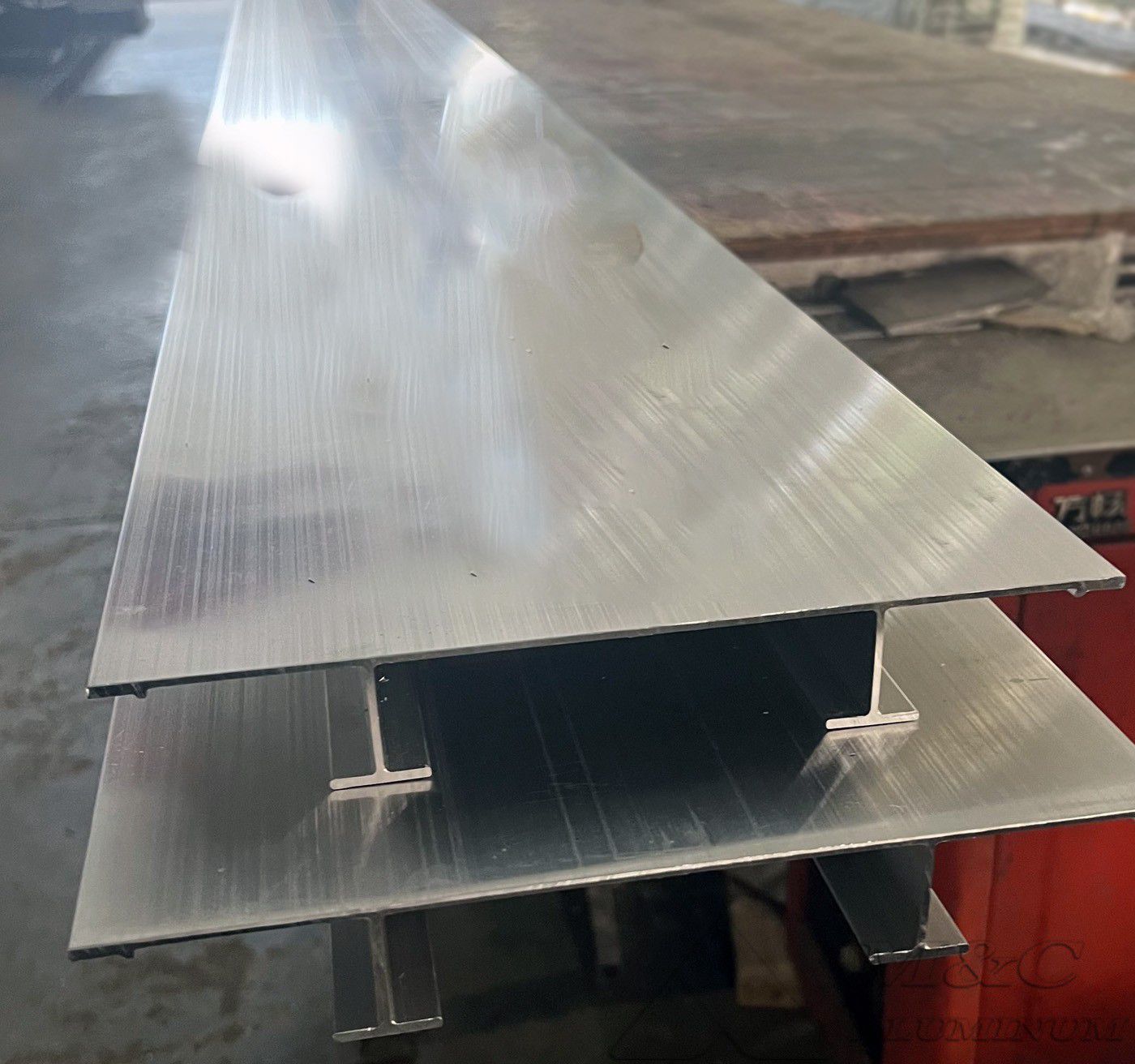

Single stiffener panel

Aluminum alloy single stiffener panel is a structural plate with a reinforcing rib attached to the aluminum alloy plate. It is characterized by a raised reinforcing rib (or "rib") only on one side of the plate or in the middle of the plate, which is used to improve the strength and rigidity of the plate and enhance its ability to resist bending and deformation.

Features

Lightweight: Aluminum alloy itself has the characteristics of light weight and low density. The single rib plate design provides additional strength while maintaining the overall lightness.

High strength: The presence of reinforcing ribs effectively increases the strength of the plate, allowing it to withstand greater loads and stresses.

Corrosion resistance: Aluminum alloy has good corrosion resistance and is suitable for outdoor, marine and other environments.

Easy processing: Aluminum alloy single rib plate can be processed and formed by pressing, extrusion, welding and other methods, which is convenient for customization.

Application

Aluminum alloy single stiffener aluminum panel is widely used in aerospace, automobile manufacturing, shipbuilding, construction, mechanical equipment and other fields. For example, the use of aluminum alloy single rib plate in the skin structure of an aircraft can improve the strength and stability of the body without significantly increasing the weight.

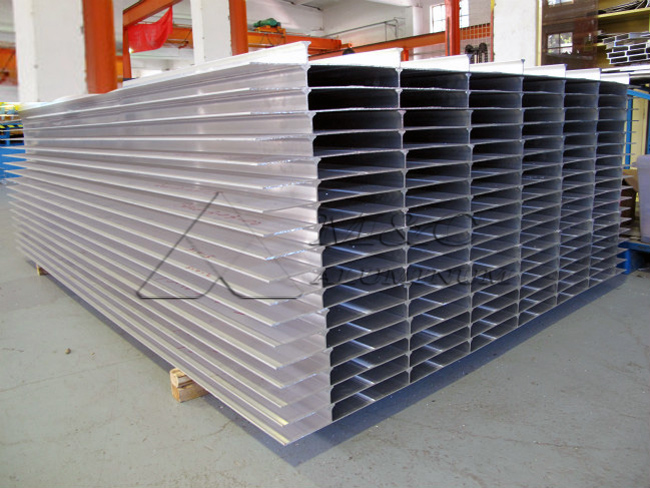

Double-stiffener panel

Aluminum alloy double-stiffener panel is a structural plate with two reinforcing ribs on the aluminum alloy plate. The two ribs are usually arranged in parallel and located on the same side or both sides of the plate, aiming to further enhance the strength and rigidity of the plate and improve its resistance to bending and deformation.

Features

Lightweight: Taking advantage of the low density of aluminum alloy, the double rib design provides high strength while keeping the plate lightweight.

Higher strength and rigidity: Compared with single rib plate, double rib plate has higher load-bearing capacity and can maintain structural stability under high stress environment.

Corrosion resistance: Aluminum alloy material has good corrosion resistance and is suitable for various harsh environments.

Easy processing: Aluminum alloy double rib plate can be made by extrusion, welding and machining, which is convenient to meet various design requirements.

Application

Aluminum alloy double-stiffener panel is commonly used in aerospace, rail transportation, shipbuilding and construction. For example, in structures such as aircraft wings and fuselages, ship decks, and vehicle floors, double-stiffener panel can provide sufficient strength and rigidity while keeping the structure light to meet strict engineering requirements.

Multi stiffener panel

Wide-width aluminum alloy ribbed plates are ribbed plates with 1 to 2 specific ribbed cross-section shapes made by a high-power extruder through an extrusion process, and then several ribbed plates are welded into wide ribbed plates of the length and width required by the designer through a stir friction welding process. This wide ribbed plate replaces the conventional plate structure in which the ribs and aluminum alloy plates are welded into an integral plate structure by melting argon arc.

The structural design of multi stiffener panel not only meets the requirements of relevant regulations of China Classification Society, but also saves a lot of aluminum alloy welding wire and welding workload, shortens the ship construction cycle, and more importantly, avoids welding deformation caused by argon arc melting welding, improves the aesthetics of the hull shape and the construction quality of the ship, and has been widely used in the design and construction of aluminum alloy ships.

Features

1. Lightweight and high strength

2. Enhanced anti-buckling ability

3. Reduced vibration and deformation

4. Improved load distribution

5. Good fatigue resistance and long service life

6. Mature manufacturing process (riveting, MIG welding)

Applications

Aerospace: Reinforcement plates are used in aircraft fuselages and wings to maintain structural integrity while keeping weight low.

Shipbuilding: Reinforcement plates are used to strengthen the hull.

Civil Engineering: Reinforcement plates can be used in bridges, buildings and other structures that require high strength with minimal material.

Specification

Our company has a large number of CCS, DNV, ABS, NK and other classification society certified marine aluminum plates and various series of automotive aluminum plates, aluminum coils, aluminum profiles, ribbed plates, steel-aluminum joints, aluminum welding wires and other spot stocks with great price advantages