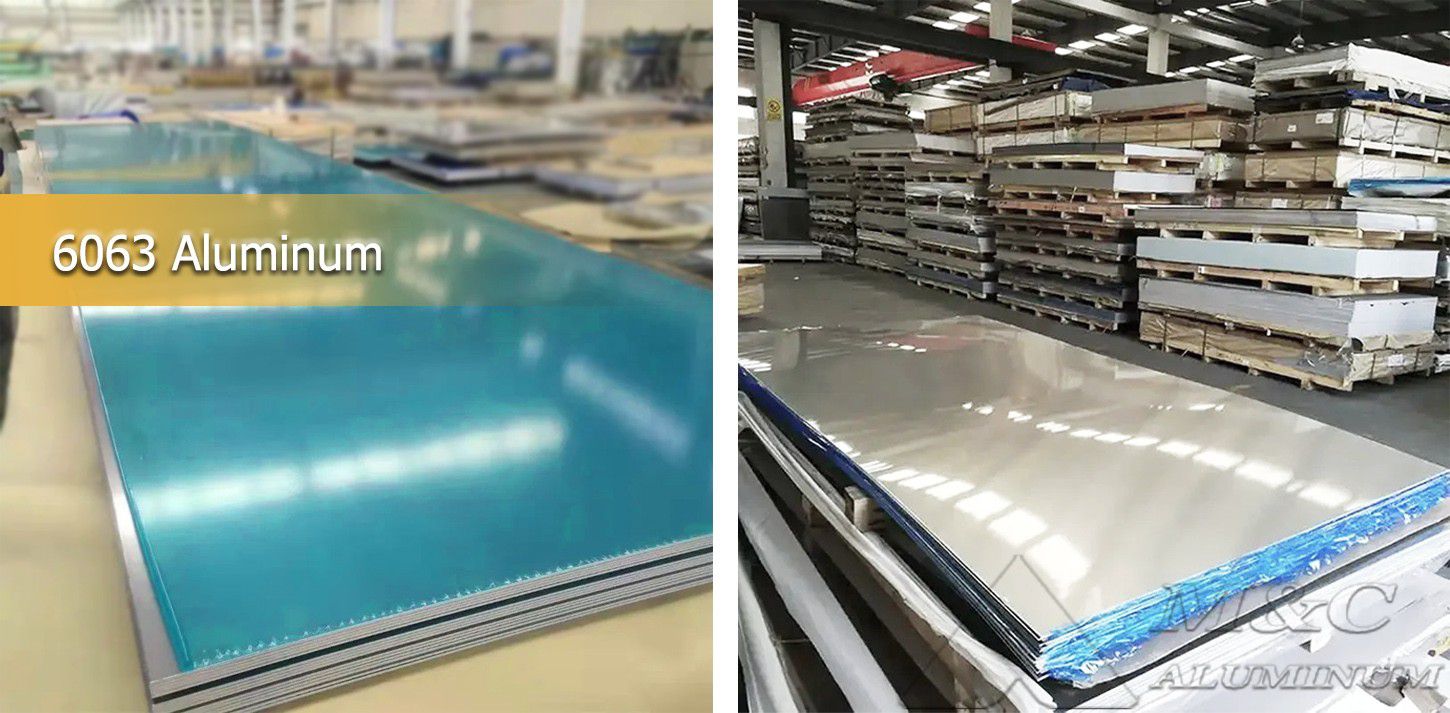

Application of aluminum alloy in ship engineering. Aluminum alloy for shipbuilding is mainly aluminum-magnesium alloy, aluminum-magnesium-silicon alloy and aluminum-zinc-magnesium alloy. 6063 alloy aluminum sheet is Al-Mg-Si high plasticity alloy, which is a heat-treated and strengthened alloy. It is light and high in strength, easy to process, with excellent weldability, extrusion and electroplating properties, good corrosion resistance, toughness, easy to polish, coating, and excellent anodizing effect. It is widely used in ships, building profiles and other fields.

The commonly used aluminum alloy profile for portholes in ship superstructures is 6063 aluminum alloy, and masts and gangways often use 6063 and 6061 aluminum alloy profiles.

Specification

6063 aluminum sheet specifications:

| Temper | T5, T6, T651 |

| Thickness | 3-50mm |

| Width | 900-2500mm |

| Length | 1000-16000mm |

| Certificate | ABS, BV, CCS, DNV, KR, LR, RINA, etc. |

| Packaging | Industry standard packaging or according to customer requirements |

6063 Aluminum chemical composition:

Marine Aluminum Alloys Composition | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Ga | Other | Al | |

| Each | Total | ||||||||||||

| 6063 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | - | 0.25 | 0.15 | - | 0.05 | 0.15 | Remainder |

6063 Physical Properties:

| Alloy | Temper | Tensile Strength Rm(Mpa) | Yield Strength Rp0.2(Mpa) | Elongation A(%) | Exfoliation corrosion | Intergranular corrosion Mg/cm2 | Certification | Standard |

| 6063 | T5 | ≥150 | ≥110 | ≥8 | - | - | DNV,GL | EN573 |

| T6 | ≥205 | ≥107 | ≥10 | - | - |

Advantages

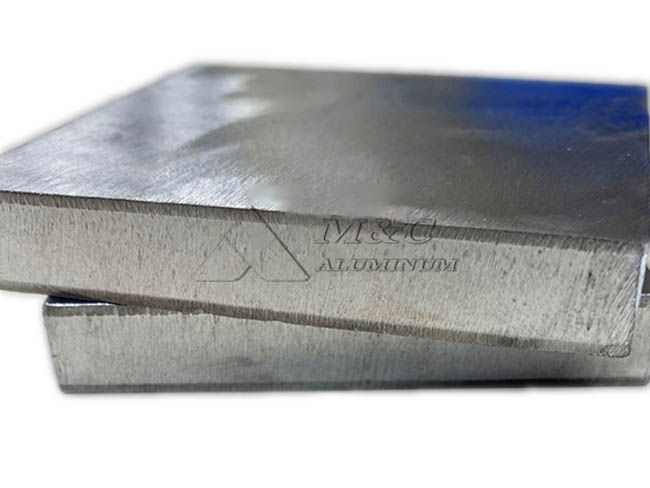

Features of 6063 marine aluminum sheet:

1. Lightweight, high strength, reducing hull weight, improving navigation speed and fuel efficiency.

2. Strong corrosion resistance, able to resist erosion in harsh environments such as seawater, and long service life.

3. Easy to process and shape, can be processed by extrusion, forging, welding and other processes.

4. Good mechanical properties and tensile strength, resist external pressure, and ensure the compressive strength of ship containers.

5. Excellent welding performance.

6. Environmentally friendly and economically recyclable.

Package

Aluminum alloy packaging and delivery

1. Paper or film the aluminum plate to ensure that the surface of the aluminum plate is intact and without scratches;

2. Plastic or kraft paper wrapping is used to prevent moisture and rain, ensuring that the aluminum plate is clean and free of dirt during transportation (each package has a moisture-proof desiccant to ensure the quality of our products in the rainy East and South China);

3. Add wooden pallets and reinforce them with steel belts to avoid collisions during transportation and ensure that the geometric shape of the aluminum plate remains unchanged;

4. Export products are packaged in wooden boxes and brackets with fumigation marks;

5. Package according to other packaging requirements of customers;

Why choose MC Aluminum

1. MC Aluminum has introduced a "1+1" hot rolling production line, with a rough rolling width of up to 3300mm and a fine rolling width of up to 2800mm, which can produce ultra-wide and ultra-thick aluminum plates.

2. Our company's marine grade 6063 aluminum plate has also been certified by DNV Norwegian Classification Society.

FAQ

Q: Can we visit your factory?

A: Of course, you are welcome at any time. However, please inform us of the factory in advance so that we can make corresponding arrangements. Thank you.

Q: What are the advantages of your company?

A: Our factory has built multiple modern production lines, including one 1+2 hot rolling production line, six 2450mm, 2050mm, 1650mm, 1450mm cold rolling production lines, two 1650mm foil rolling production lines, two 1850mm continuous rolling production lines, and one roller coating production line. In addition, we have also introduced 8x20 annealing furnaces, tension straightening machines, tension pre-stretching machines, cutting machines, cleaning equipment, testing machines, and packaging equipment from home and abroad.

Q: How to ensure quality?

A: Provide factory test certificates, such as: classification certificates ABS, BV, CCS, DNV, KR, LR, RINA, etc. Third-party inspections can be accepted if necessary.

Q: When is your delivery time?

A: For stock products, it will be shipped within 3-5 days after receiving the deposit; if we need to produce the product, it depends on the factory schedule and the purchase quantity. We will do our best to complete the production as soon as possible.

Q: Can you provide samples?

A: There are small samples in the store, and samples can be provided free of charge.

Customized samples require us to communicate to determine the delivery time.