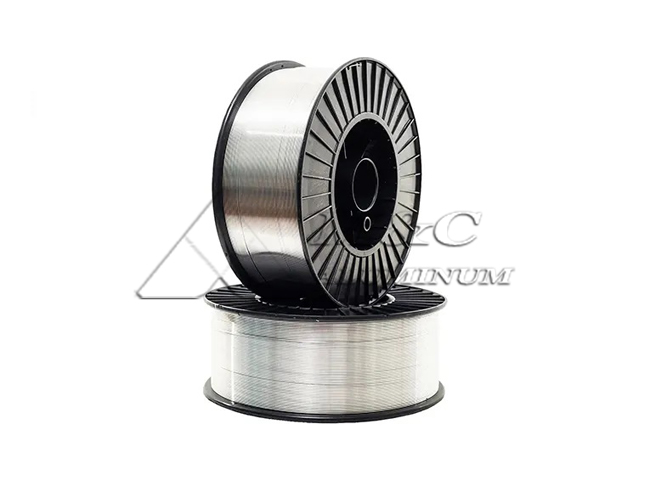

Welding wire is a metal wire welding material used as a filler metal or as a conductive material. Its raw material is aluminum alloy. Aluminum welding wire manufacturers recommend that the commonly used grades of marine aluminum welding wire are 5183 and 5356.

ER5183 & ER5356

ER5183 aluminum welding wire is an aluminum-magnesium welding wire containing nearly 5% magnesium and a higher manganese content. It has a higher magnesium content requirement for welding, has a strong tensile strength, and has excellent resistance to seawater corrosion and low temperature performance. The weld is white after anodizing, which can provide a good color match for the welded joint.

ER5356 aluminum welding wire is an aluminum alloy welding wire with high strength and corrosion resistance. It uses pure aluminum as the welding core and adds an appropriate amount of magnesium, silicon and other elements to maintain the corrosion resistance of the welding surface. It is a general-purpose aluminum-magnesium alloy welding wire with high silicon, low magnesium and good fluidity. Due to its excellent mechanical properties and corrosion resistance, it is widely used in aluminum alloy welding in aviation, aerospace, automobiles, bicycles, fishing rods, ships, construction, cables and other fields. 5356 aluminum-magnesium welding wire has classification society certification.

Specifications

Aluminum welding wire specifications:

| Alloy | 5183, 5356 |

| Aluminum welding wire standard | GB/T10858-2008 |

| Wire diameter | 0.8, 1.0, 1.2, 1.6, 2.0, 2.4, 3.0, 3.2, 4.0, 5.0, 6.0 (mm) |

| Wire reel size | D300 (9kg), D270 (7kg), D200 (2kg), D100 (0.5kg) |

| Packaging status | coiled wire, straight bar, coiled wire, barreled |

| Wire features | 5% magnesium content, strong versatility, high strength, good color after anodizing after welding. |

| Recommended welding method | AC argon arc welding, pure argon protection. Before welding, the weld mouth of the workpiece needs to be cleaned, and air, weldment, and welding wire should not be damp. |

| Processing technology | extrusion method, liquid drawing method |

| Welding applications | Aluminum alloy welding - automotive aluminum alloy fuel tanks, doors, bodies, frames, stage equipment, aluminum alloy doors and windows, guardrails, aluminum shells, aluminum cans, pressure vessels, aluminum alloy furniture, aluminum templates, petrochemical silos, medical equipment, ships and yachts, transportation facilities, etc. |

Aluminum welding wire chemical composition:

| Grade | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 5356 | 0.25 | 0.40 | 0.10 | 0.05-0.2 | 4.5-5.5 | 0.05-0.2 | 0.1 | 0.06-0.2 | Balance |

| 5183 | 0.40 | 0.40 | 0.10 | 0.50-1.0 | 4.3-5.2 | 0.05-0.2 | 0.25 | 0.15 | Balance |

Typical Features:

Alloy | 5183 | 5356 |

Melting range | 1075-1180°F | 1060-1175°F |

| Conductivity | 16-19Ω·m/mm2 | 29%lACS(O) 27%lACS(H18) |

Density | 2.66g/mm2 | 2.66g/mm2 |

Corrosion resistance | A(Gen)A(SCC) | A(Gen)A(SCC) |

Thermal expansion coefficient (20℃~300℃) | 23.7×10¯⁶/K | 23.7×10¯⁶/K |

| Thermal conductivity (20℃) | 110-120W/m.k | 110-150W/m.k |

Application

5356 5183 aluminum welding wire application:

5356 application: used as a universal welding material for aluminum-magnesium alloy TIG welding, MIG welding and oxy-acetylene welding, and is also widely used in the welding of aluminum-zinc-magnesium alloys and the repair welding of aluminum-magnesium castings. Such as locomotive carriages, chemical pressure vessels, bicycles, aluminum skateboards and other sports equipment, military production, shipbuilding, aviation and other industries.

5183 application: used as a filler metal for aluminum-magnesium alloy argon arc welding, and is used in locomotive carriages, chemical pressure vessels, nuclear industry, shipbuilding, refrigeration, boilers and aerospace industries.

Chosse US

Why choose MC Aluminum for aluminum alloy for welding wire?

1. The surface of the product is smooth, bright and clean, without burrs, dents, creases or other oxidized impurities.

2. Provide classification society certificates: ABS, BV, CCS, DNV, KR, LR, RINA, etc.

Packaging & Shipping

Plastic reel net weight 5kg 15kg 20kg; 72 cartons on pallet, 22 pallets in 20GP container

Net weight per barrel 100kg 250kg 350kg; 2 or 4 barrels per pallet

Waterproof paper & plastic layer wrapped on reel, one reel in one carton

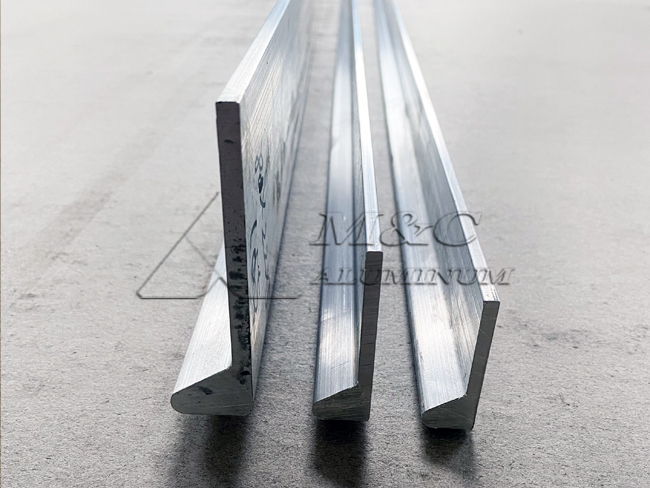

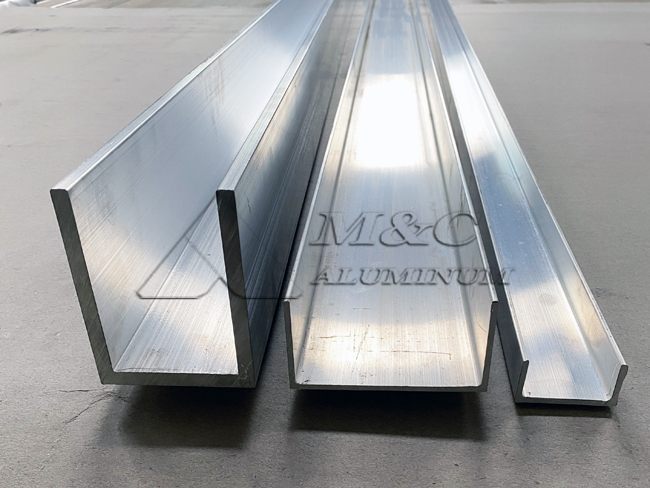

MC Aluminum has a large stock of competitively priced marine aluminum plates and various series of automotive aluminum sheets, aluminum coils, aluminum profiles, ribbed plates, steel-aluminum joints, aluminum welding wires, etc. certified by classification societies such as CCS, DNV, ABS, and NK.