Introduction

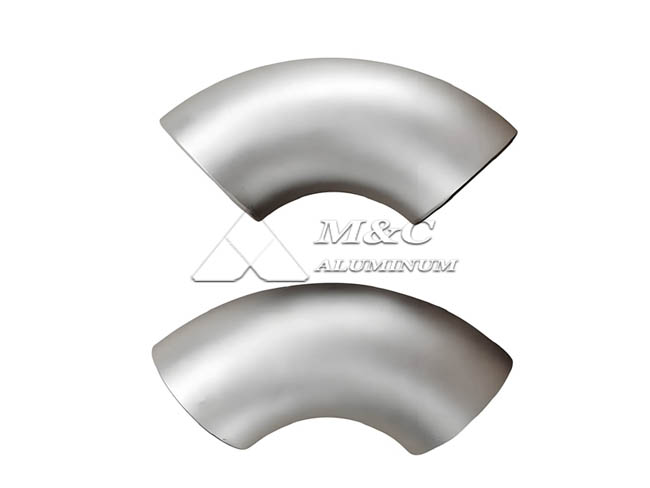

An aluminum elbow is a type of pipe fitting used to change the direction of fluid flow in piping systems. Made from aluminum materials, these elbows offer lightweight properties, corrosion resistance, and cost-effectiveness. Depending on the bending angle and pipe diameter, aluminum elbows are available in various types.

Compared to steel elbows, aluminum elbows provide lower weight, better corrosion resistance, superior thermal conductivity, and easier processing, making them ideal for applications requiring lightweight structures, high heat dissipation, and excellent corrosion resistance.

Common Aluminum Alloys for Elbows

Aluminum elbows are typically made from alloys such as 1060, 3003, 5052, 6061, 6063, and 7075, known for their excellent corrosion resistance and mechanical strength.

Types

Types of Aluminum Elbows

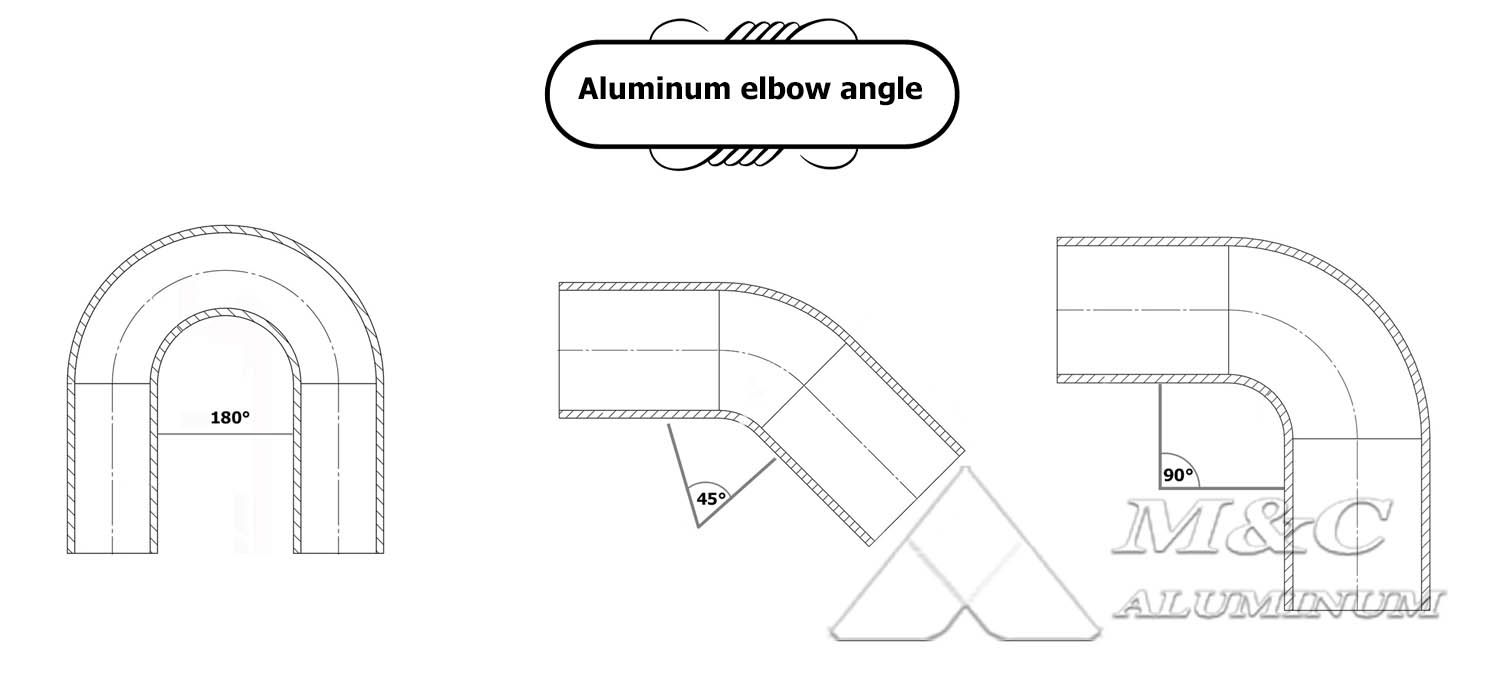

90-Degree Elbow – Also called a right-angle elbow, commonly used where a sharp directional change is needed.

45-Degree Elbow – Helps reduce flow resistance and allows a more gradual change in direction.

180-Degree Elbow – Also known as a U-shaped elbow, used where fluid return flow is required.

Custom Angle Elbows – Can be manufactured with special angles such as 30°, 60°, or other specific degrees as needed.

The 45-degree or 90-degree designation refers to the bending angle of the butt-weld joint used to change the flow direction. Besides these standard angles, custom elbows can be fabricated to meet specific engineering requirements.

Specification

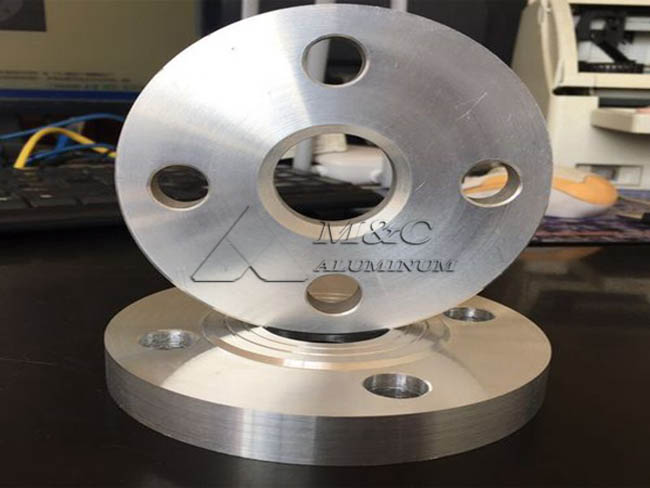

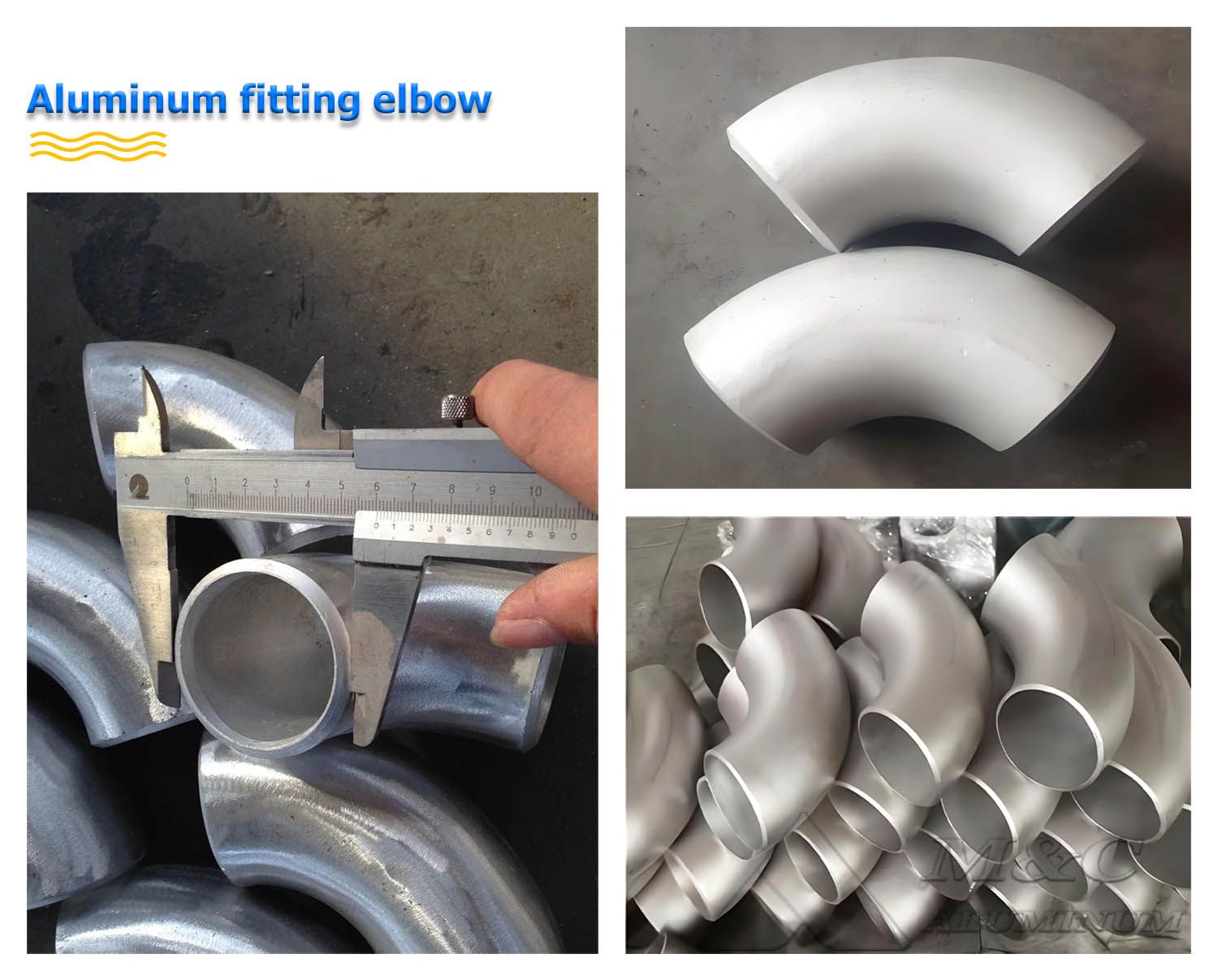

Aluminum fitting elbow specifications

Form | Seamless and welded |

Fittings Shape | Elbows, Tees, Reducers, Caps,Nipples |

Size Range | 1/2''-24'' |

Material | 1000-7000 Series |

Alloy | Aluminum 6061-T6,3003/6061/6063/5083/5086/5052 ,etc |

Color | Black,galvanized,natural,brass..or customized color as client's request. |

| Elbow Angle | 180 degrees, 90 degrees, 45 degrees, other customized |

Wall Thicknes | SCH10--SCH160, STD--XXS |

Ends Type | Butt weld |

Surface treatment | Anodized |

Standard | ANSI B16.9, ASTM B361 |

Finish | Mill Finish |

Technics | Forged |

Application | Large Marine Craft, Containers, Railroadcars |

Specialized manufacturer of | 45º Elbows, Pipe Bend, Tees, Crosses, Stub End, Reducers, 90º Elbows, Pipe Cap |

| Package | Pallet/wooden box (fumigation-free) |

Advantages

Advantages of Butt Weld Aluminum Elbows

1.Lightweight & High Strength: Aluminum has a low density, making it ideal for lightweight industries like aviation and automotive manufacturing.

2.Superior Corrosion Resistance: The natural oxide layer on aluminum provides excellent resistance to acids, alkalis, and oxidation, making it suitable for humid or corrosive environments.

3.Excellent Thermal Conductivity: Aluminum conducts heat much better than steel, making it ideal for heat exchangers and high-temperature piping systems.

4.High Machinability: Easy to cut, weld, bend, and machine, allowing compatibility with various connection methods.

5.Low Fluid Resistance: The smooth inner wall of aluminum elbows reduces flow resistance, improving transportation efficiency.

6.Aesthetic & Durable: Polishing, anodizing, and other surface treatments enhance both appearance and durability.

7.Environmentally Friendly & Recyclable – Aluminum is 100% recyclable, making it an eco-friendly choice.

Applications

Applications of Aluminum Elbows

1.Plumbing Systems: Used in water pipelines to change flow direction.

2.Industrial Pipelines: Used in gas and liquid transport systems across various industries.

3.Automobile Manufacturing: Commonly found in engine exhaust systems, cooling systems, and fluid pipelines.

4.Architectural & Decorative Uses: Used in indoor plumbing and outdoor structural supports, including curtain walls and drainage systems.

5.Refrigeration & HVAC Systems – Directs the flow of refrigerants in cooling and air conditioning units.