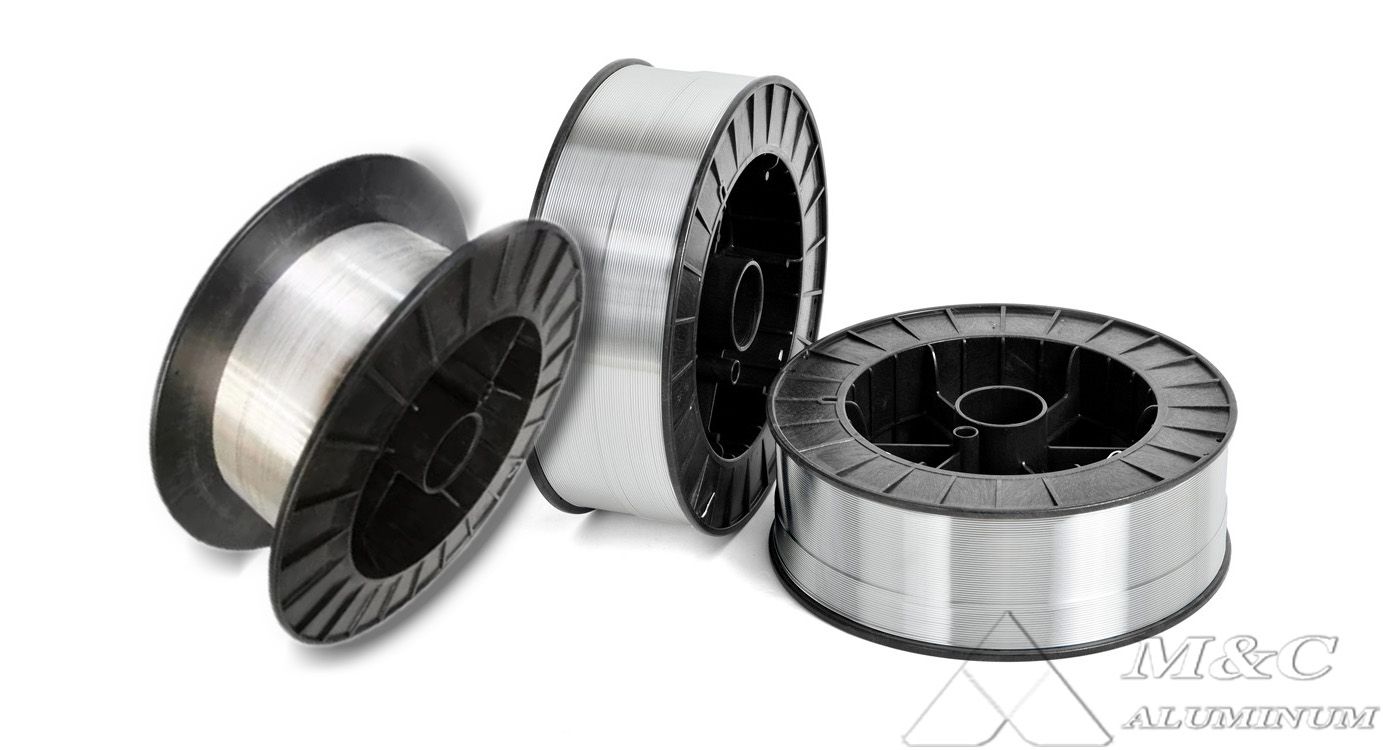

The commonly used aluminum welding wire models on ships are 5356 and 5183 aluminum-magnesium welding wire. When talking about aluminum wire, 90% of people think it refers to the 5356 model, because 5356 aluminum-magnesium welding wire is too common and often used in various industries.

ER5356 and ER5183

ER5356 is usually used as ALMg5, which is an aluminum alloy filler metal containing 5% magnesium. It can be used for MIG or TIG welding processing. It has good seawater corrosion resistance and can generally be used for welding of base materials 5050, 5052, 5083, 5356, 5454 and 5456. It is white in color after anodizing and has a tensile strength of 290MP.

ER5183 is another commonly used aluminum-magnesium welding wire model with high strength and good corrosion resistance. It is suitable for welding 5083, 5456, 6061 and other aluminum alloys with high magnesium content.

The main difference between ER5356 and ER5183 aluminum-magnesium welding wires lies in their chemical composition, performance characteristics and application areas.

ER5356 VS ER5183

1. Chemical composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| ER5356 | 0.25 | 0.40 | 0.10 | 0.05-0.20 | 4.5-5.5 | 0.05-0.20 | 0.10 | 0.06-0.20 | Remainder |

| ER5183 | 0.40 | 0.40 | 0.10 | 0.50-1.0 | 4.3-5.2 | 0.05-0.25 | 0.25 | 0.15 | Remainder |

The chemical composition of ER5356 aluminum-magnesium welding wire contains magnesium content between 4.5% and 5.5%, while the magnesium content of ER5183 aluminum-magnesium welding wire is between 4.3% and 5.2%. Both welding wires contain high magnesium elements, but ER5183 has a slightly lower magnesium content, which determines their differences in performance and application.

2. Physical and mechanical properties

5356 welding wire: Its weld metal has good physical properties such as yield strength, tensile strength and elongation. Specifically, the yield strength Rp0.2 is about 110 MPa, the tensile strength Rm is about 240 MPa, and the elongation A5 is about 17% at a test temperature of 20°C. In addition, it has excellent corrosion resistance and is particularly suitable for seawater environments.

5183 welding wire: Compared with 5356, the welds produced by 5183 welding wire have higher tensile strength. This makes it more suitable for occasions where high-strength connections are required. At the same time, it also has good corrosion resistance.

3. Application fields

5356 welding wire: Due to its high strength and good corrosion resistance, it is widely used in rail transportation, automobiles, ships, pressure vessels, brackets, shells, and workpieces that need to be anodized after welding.

5183 marine grade aluminum welding wire: It focuses more on marine and low-temperature industrial applications, such as shipbuilding, air separation industry, tank trucks, etc. In addition, it is also commonly used in aerospace and construction fields, especially those with high requirements for welding strength.

4. Welding performance

Both have good welding performance and are suitable for a variety of welding positions and different shielding gases. However, in specific applications, the choice of welding wire needs to be considered comprehensively based on factors such as the composition of the base material, welding requirements, and working environment.

The above is the difference between ER5356 and ER5183 aluminum-magnesium welding wires. In general, 5356 is more suitable for conventional aluminum alloy welding, while 5183 is suitable for applications with higher strength requirements or harsh corrosion environments.

MC Aluminum can customize the production of aluminum profiles, always have a large amount of aluminum profile inventory, stable product quality, advanced equipment, skilled technology, exported to many countries and regions overseas, and is highly trusted by customers.