5083-H111 I-type marine aluminum profiles are commonly used in ship structures and hull frameworks as anodized aluminum alloy profiles. These profiles belong to the 5083 series aluminum alloy and have undergone specific heat treatment and processing, providing excellent mechanical properties and corrosion resistance. They are particularly suitable for marine environments and are widely used in the construction and maintenance of ships, warships, commercial vessels, and other surface vessels.

Product Introduction of 5083-H111 I-type Marine Aluminum Profiles

5083 Marine Aluminum Alloy

5083 marine aluminum alloy is a high-strength, highly corrosion-resistant aluminum alloy, widely used in shipbuilding, marine engineering, and other structures that require resistance to seawater corrosion. It is a type of aluminum-magnesium alloy within the 5083 series, making it particularly suitable for hull and frame construction in marine environments.

Advantages of 5083 Aluminum Alloy

Strong Corrosion Resistance: Particularly suitable for marine environments, it resists seawater corrosion, making it ideal for ship structures and frames.

High Strength: Compared to other aluminum alloys, it has significantly higher strength, allowing it to withstand large structural stresses.

Excellent Weldability: It has good welding properties, making it suitable for joining with other aluminum alloys or materials, and is ideal for complex hull structures.

Good Low-Temperature Performance: It remains stable in low-temperature environments, making it suitable for use in cold sea areas.

H111 Heat Treatment Condition

H111 is a heat treatment condition for aluminum alloys, indicating that the alloy has undergone some work hardening but has not been fully heat-treated. In this state, the alloy exhibits some strength but remains relatively soft and can be further formed or adjusted during subsequent processing.

In the H111 state, 5083 aluminum alloy is suitable for ship structural components that require high strength, corrosion resistance, and a certain degree of flexibility and ductility.

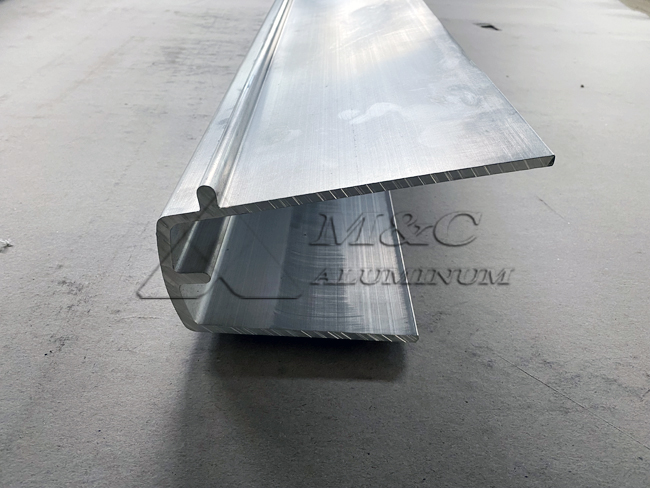

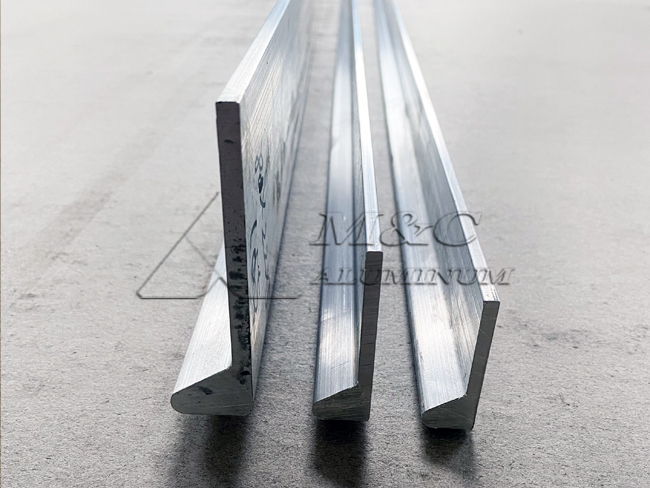

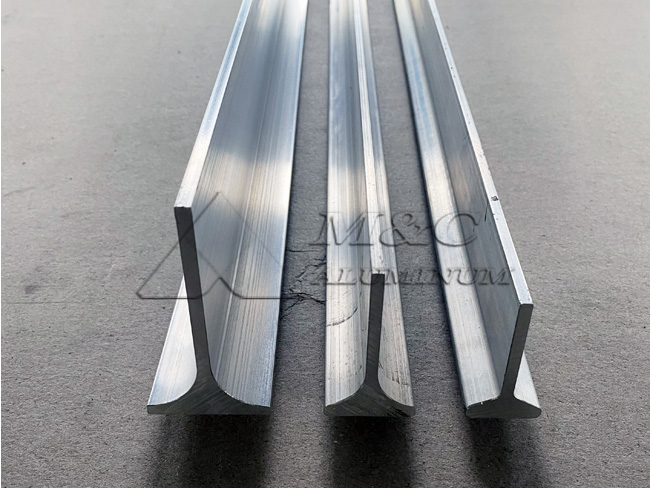

I-type Aluminum

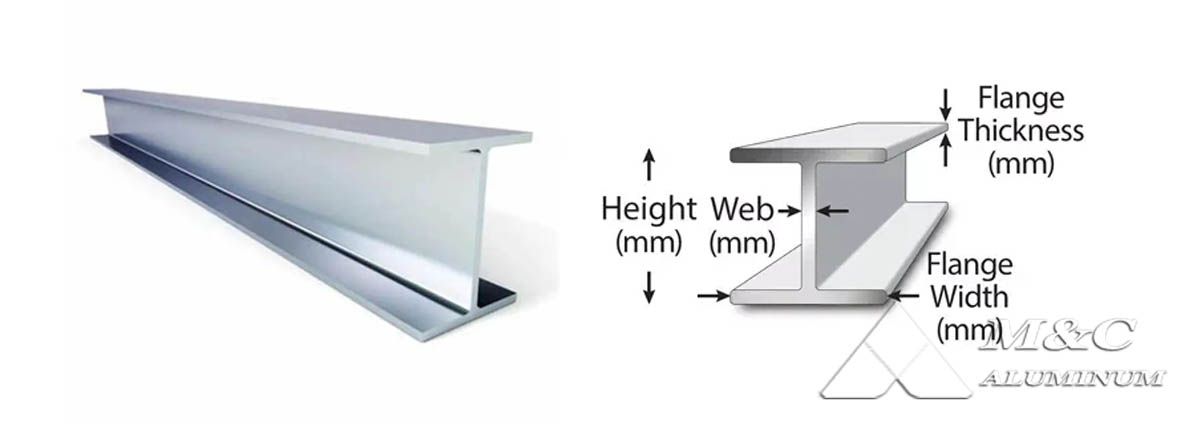

I-type aluminum profiles are a common type of aluminum alloy profile, shaped like the letter "I" with two parallel long edges and a longitudinal support in the middle. This design provides excellent bending and torsional resistance, making it ideal for use in ship frameworks, decks, beams, and other load-bearing parts.

Structural Stability: The design of I-type aluminum profiles offers excellent bending resistance, which is especially important in shipbuilding. It effectively distributes and withstands the pressure and vibrations of the hull.

Space and Weight Savings: Compared to traditional steel profiles, aluminum alloy profiles are lighter, helping to reduce the overall weight of the ship, thus improving speed and fuel efficiency.

Ease of Processing: Aluminum profiles are easy to cut, weld, drill, and perform other processing operations, facilitating installation and adjustments.

5083 Extruded Aluminum Profile Specifications

| Alloy | 5083 |

| Temper | H111, H116, H112, H32, etc. |

| Thickness | 3-50mm |

| Length | 1m - 12m |

| Process | Extrusion |

| Processing Services | Cutting, stamping, drilling, milling, bending, welding, turning, casting, CNC machining, etc. |

| Certificates | CCS, BV, ABS, etc. |

Chemical Composition of 5083 Marine Aluminum Alloy (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

Advantages of 5083 I-Shaped Aluminum Profiles

1.Corrosion Resistance: 5083 aluminum alloy has excellent resistance to seawater corrosion, making it ideal for use in humid, high-salinity marine environments, overcoming the corrosion problems faced by traditional materials like steel in seawater.

2.High Strength: 5083 aluminum alloy has a much higher strength than standard aluminum alloys, meeting the demands for ship structures that need to withstand large pressures and loads.

3.Lightweight and High Strength: Compared to traditional steel, aluminum alloys are less dense, significantly reducing the overall weight of the ship, which improves speed and fuel efficiency.

4.Environmentally Friendly: Aluminum alloy is a recyclable material, and using 5083 aluminum alloy profiles helps reduce resource consumption and lowers environmental impact.

5.Good Weldability: 5083 aluminum alloy has excellent weldability, meeting the needs for connecting ship structural components, which is especially important in complex hull structures.

Applications of 5083-H111 I-Shaped Aluminum Profiles

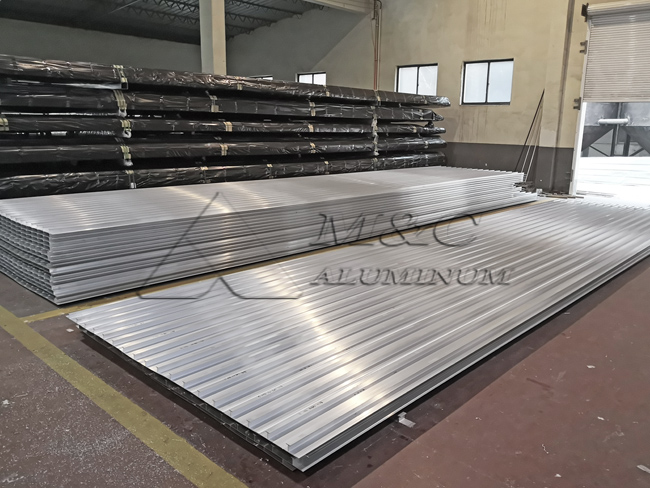

Ship Structures: Used in the main structural framework of ships (such as deck beams, hull frames), providing strong support and lightweight characteristics, enhancing stability and navigation efficiency.

Commercial Ships and Naval Vessels: Used as structural support in commercial vessels and naval warships to withstand pressure and resist saltwater corrosion, reducing weight, and improving speed and fuel efficiency.

Hull Panels: Used for reinforcing and supporting hulls, reducing weight while maintaining strength, and combined with aluminum alloy plates to form lightweight, high-strength hulls.

Offshore Platforms: Widely used in marine oil platforms and floating platforms, offering excellent corrosion resistance and structural stability.

Fast Vessels: Used in high-speed boats and performance yachts to effectively reduce the hull weight, improving acceleration and speed to meet the demands of high-speed operations.

MC Aluminum is a professional aluminum product processing manufacturer, specializing in producing marine aluminum plates, medium-thick plates, aluminum profiles, FSW panel, aluminum tube fittings, and other products. Common models include 5083, 5086, 5052, 5456, 6061, 6082, 6063, and other marine aluminum alloys. The products are certified by CCS, BV, ABS, and other classification societies. They are widely used in the decks, engine mounts, hull sides, bottom outer plates, and other parts of commercial ships, yachts, grain carriers, fishing boats, workboats, sand carriers, etc. The products are reliable in quality, exported overseas, available for direct sales from the manufacturer, with sample provision. Welcome to visit the factory for inspection.