Product Introduction

As a typical representative of the Al-Mg alloy series, the 5083-H321 Marine-grade Aluminum Plate has become a core material in modern shipbuilding due to its high strength, excellent marine corrosion resistance, and outstanding processability. In marine environments, its resistance to chloride ion corrosion reduces the frequency of hull maintenance and extends the service life. Its welding and cold forming capabilities support the integrated manufacture of complex hull structures, making it suitable for high-demand applications such as decks, bulkheads, and LNG storage tanks. Currently, this material has been certified by international classification societies such as CCS/ABS, and with innovations in processes like controlled temperature rolling, production efficiency and cost advantages have been further enhanced.

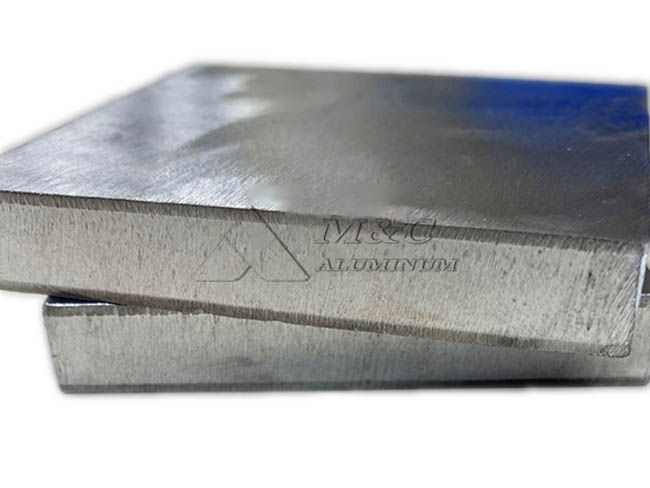

H321 State Characteristics

The H321 state refers to aluminum alloys that undergo semi-cold hardening treatment. This process ensures a balance between tensile strength and yield strength while maintaining cold-working properties such as cutting and bending. H321 aluminum plates typically have good strength and toughness, retaining some plasticity for further processing and use.

5083 H321 Aluminum Alloy Specifications

| Thickness | 3-50mm |

| Width | 1000-2650mm |

| Length | 1000-16000mm |

| Surface Treatment | Smooth rolled surface, suitable for use or further processing. |

| Certification | ABS, DNV, LR, etc. |

| MOQ | 1-3 tons |

| Applications | Hull structures, bulkheads, engine beams, decks, etc. Additionally, small diameter aluminum tubes are suitable for shipbuilding, and larger pipe rods are used for masts, beams, columns, and other components. |

Mechanical Properties

| Mechanical Property | Value |

| Proof Stress | 240 Min MPa |

| Tensile Strength | 330 MPa |

| Elongation A50 mm | 17% |

| Shear Strength | 185 MPa |

| Vickers Hardness | 95 HV |

General Physical Properties

| Physical Property | Value |

| Density | 2.65 g/cm³ |

| Melting Point | 570°C |

| Thermal Expansion | 25 x 10⁻⁶/K |

| Modulus of Elasticity | 72 GPa |

| Thermal Conductivity | 121 W/m·K |

| Electrical Resistivity | 0.058 x 10⁻⁶ Ω·m |

Chemical Composition (%)

| Alloy | Si | Fe | Mn | Mg | Cu | Zn | Other:Each | Other:Total | Al |

| 5083-H321 | 0.10 | 0.20 | 0.15-0.4 | 4.0-4.9 | 0.10 | 0.10 | 0.05 | 0.15 | Remainder |

5083 H321 Marine-grade Aluminum Plate Features

1. High Strength: 5083 H321 aluminum alloy has high tensile strength, able to withstand large external pressures, making it ideal for ship hulls and offshore platform structures.

2. Excellent Corrosion Resistance: Due to its high magnesium content, 5083 aluminum alloy exhibits excellent corrosion resistance in seawater, humid air, and salt spray environments, making it an ideal material for ship hulls, bodies, and underwater structures.

3. Fatigue Resistance: This alloy demonstrates good fatigue resistance under dynamic loads, making it suitable for long-term service in marine environments.

4. Good Workability: 5083 aluminum alloy can be processed using traditional methods like cutting, drilling, bending, and stretching, offering strong adaptability.

5. Good Weldability: Excellent weldability, suitable for arc welding, gas welding, and other welding methods. It is recommended to use 5183 or 5356 aluminum welding wires for welding.

6. Certifications: Meets stringent quality standards, suitable for key applications in marine, industrial, and defense sectors.

Applications of 5083 Marine Aluminum Plate

Marine and Coastal Projects:

Hulls, decks, and structural components.

Dock structures, ramps, and walkways.

Transportation and Vehicles:

Lightweight, durable panels for trucks, trailers, and caravans.

Tank trucks and other vehicles requiring corrosion-resistant materials.

Industrial Applications:

Pressure vessels, storage tanks, and chemical containers.

Heavy-duty equipment that requires durable materials.

Construction and Structural Uses:

Roofs, cladding, and external walls for industrial and coastal buildings.

Structural components exposed to extreme weather or environmental conditions.

Defense and Aerospace:

Due to its high strength-to-weight ratio and environmental resistance, it can be used in military-grade applications.

DIY and Custom Manufacturing:

Ideal for creative projects, mechanical parts, and custom designs requiring durable aluminum plates.

MC Aluminum specializes in the production of 5083 marine aluminum plates, including 5083-H112, 5083-H32, 5083-H116, and 5083-H111 aluminum alloys. In addition, we also offer other marine-grade alloys and aluminum profiles such as 5086, 5456, 5059, 5754, 6061, 6082, and 6063, all of which meet the highest standards for marine applications. Our products are exported to numerous countries worldwide, and we offer direct sales from the factory, along with sample provision and competitive prices.