5052-H32 aluminum alloy is an aluminum alloy with excellent corrosion resistance, widely used in marine, chemical and automotive industries. Its main components are aluminum, magnesium and a small amount of chromium, which makes it excellent in strength, ductility and weldability. The yield strength of 5052-H32 aluminum alloy is high, usually up to 193 MPa, and the tensile strength is about 228 MPa, which enables it to maintain good shape stability when subjected to large loads.

5052-H32 aluminum alloy also has good formability and is easy to process through stamping, bending and other processes. It is suitable for manufacturing parts of various complex shapes. In terms of chemical corrosion resistance, 5052 aluminum alloy shows excellent corrosion resistance to seawater, salt spray and many chemicals, so it is particularly common in applications such as ships, oil and gas pipelines and storage tanks.

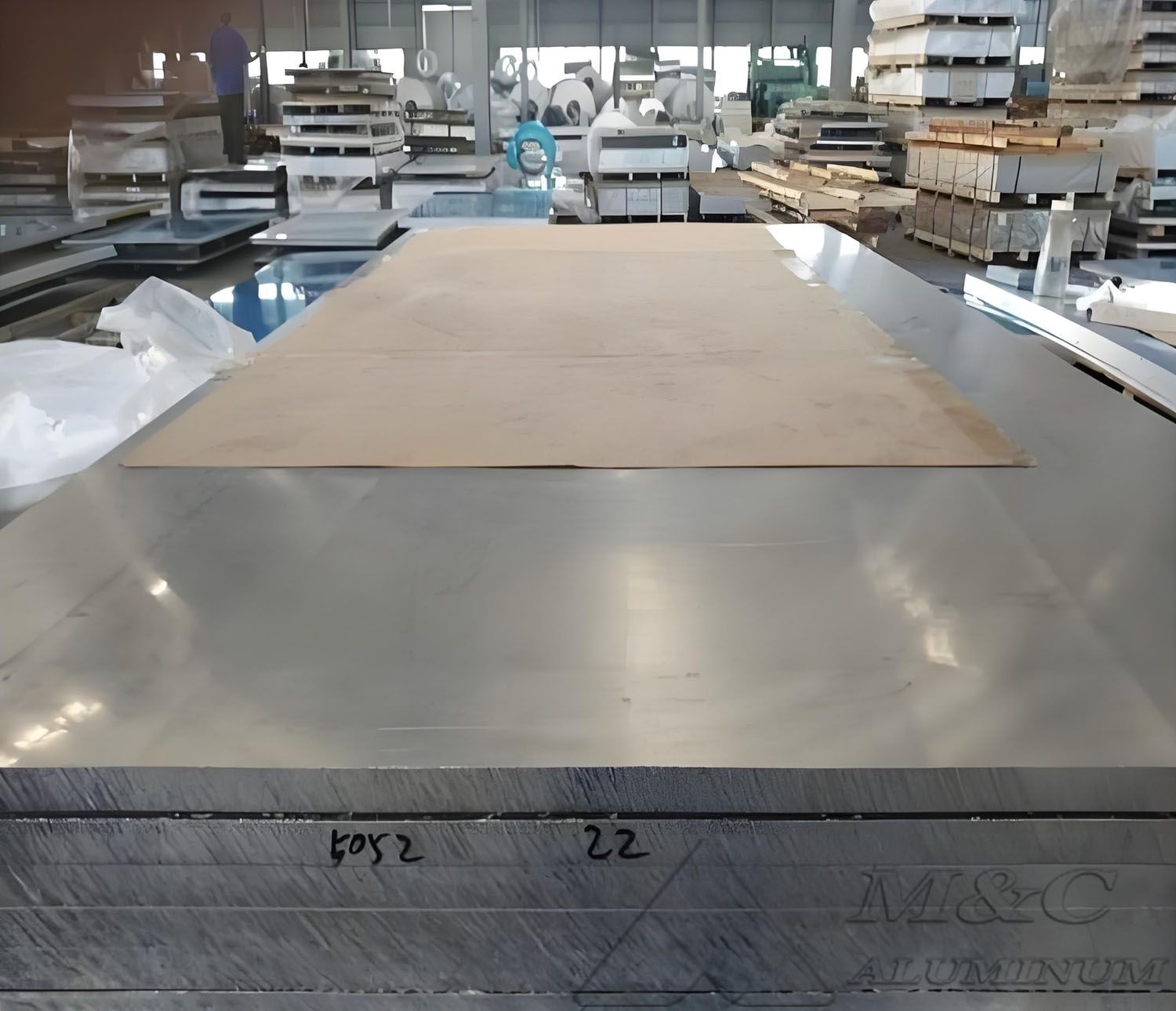

5052 marine grade aluminum alloy specifications

| Alloy | 5052 |

| Temper | H111 H112 H116 H321 T6 T651 |

| Thickness | 3-50mm (thickness tolerance +/-1.5%) |

| Width | 100-2650mm (width tolerance +/-1mm) |

| Length | 100-16000mm |

| Surface quality | no oil stains, dents, inclusions, scratches, stains, oxidation discoloration, fractures, corrosion, roller marks, dirt streaks and other defects that affect use |

| Packaging | Export standard wooden pallet |

5052 chemical composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other: Each | Other: Total | Al: Min. |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | remainder |

5052 marine aluminum plate features

1. Excellent corrosion resistance: It has excellent corrosion resistance to seawater, salt spray and industrial atmospheric environment, suitable for fields such as ships and marine engineering.

2. Higher strength: The strength is higher than pure aluminum, but lower than 6xxx and 7xxx series aluminum alloys, meeting most structural needs.

3. Good machinability: Easy to weld, form and machine, suitable for complex designs.

4. Excellent ductility: suitable for deep stamping and other high plastic forming processes.

5. Moderate fatigue strength: performs well under vibration and repeated loads.

Marine grade aluminum 5052 is widely used in the following fields due to its unique properties

1. Ships: used to manufacture hulls, decks, bulkheads and other components, which can withstand the corrosion of the marine environment.

2. Offshore platforms: used to build offshore drilling platforms, oil production platforms, etc., to ensure the stability and safety of the structure under harsh sea conditions.

3. Seawater desalination equipment: used to manufacture pipes, containers and other components in seawater desalination equipment, which can withstand the corrosion of seawater.

4. Other industrial applications: such as automotive manufacturing, aerospace, food processing, medical equipment and other fields, 5052 aluminum is also often used to manufacture various components.

MC Aluminum is a professional marine aluminum plate manufacturer, producing 5083 aluminum plates, 5052 aluminum plates, 6061 aluminum plates, 6082 aluminum plates, etc., with multiple classification society certificates such as CCS, BVLR, ABS, DNV-GL, etc. The product quality is stable, the models are complete, and it can be customized according to customer needs. It is exported to many countries and regions overseas, factory direct sales, and preferential prices.