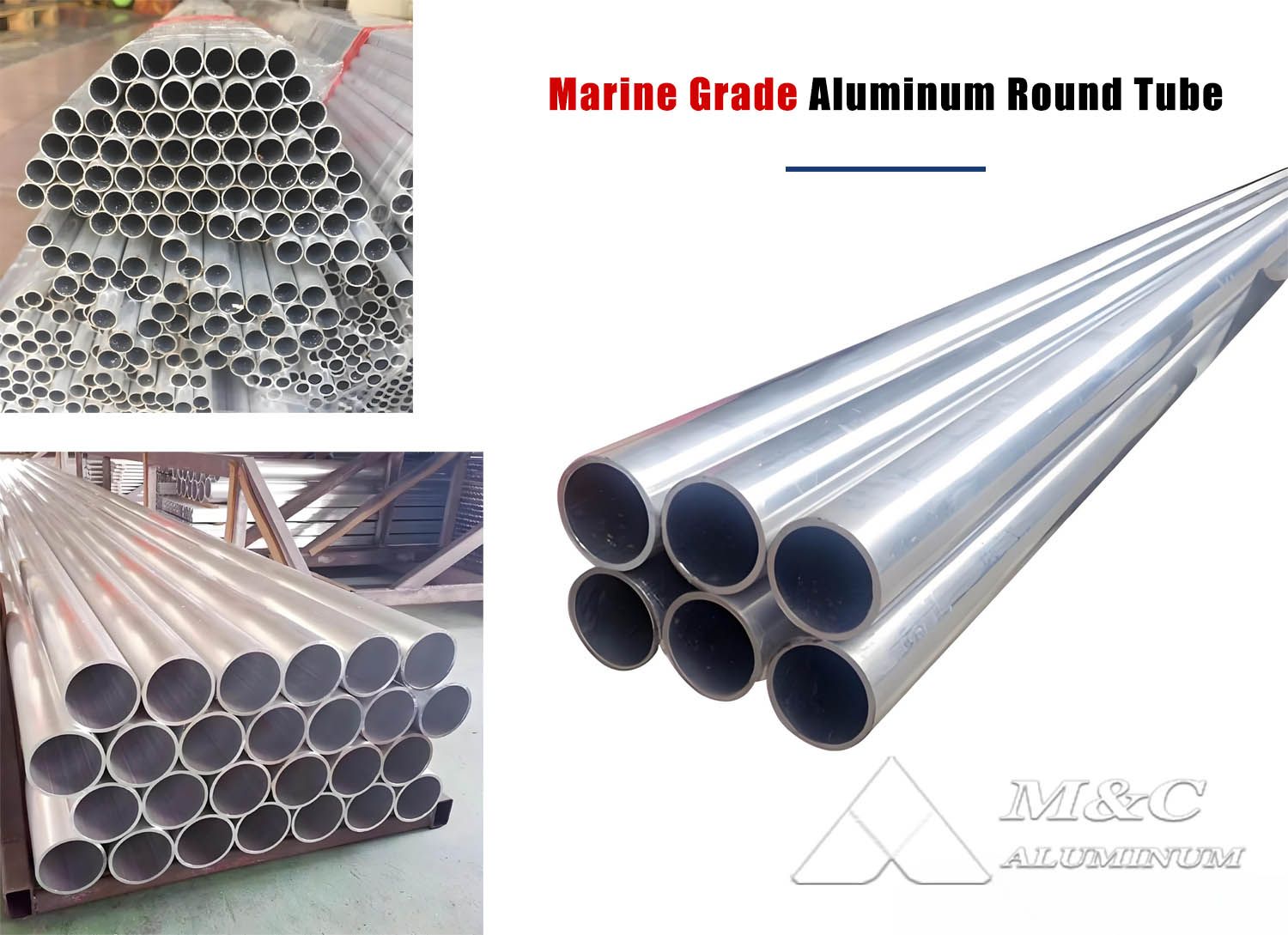

With the continuous advancement of modern shipbuilding technology, material selection plays a crucial role in ship performance and service life. Among various materials, marine-grade extruded aluminum round tubes stand out due to their exceptional physical properties and superior corrosion resistance, making them an essential choice for manufacturing ship components.

Marine-grade extruded aluminum round tubes (seamless) commonly use aluminum alloys such as 6061 and 6082, known for their excellent mechanical properties and corrosion resistance. After T6 heat treatment, these alloys achieve higher strength and hardness, meeting the rigorous demands of complex marine environments.

Introduction to 6061 and 6082 T6 Aluminum Round Tubes

6061 Aluminum Alloy:

6061 marine aluminum alloy features good corrosion resistance, excellent machinability, high toughness, and resistance to deformation. It is heat-treatable, with moderate plasticity during annealing. It also boasts outstanding weldability, making it a superior marine-grade aluminum tube material.

In addition to these characteristics, our 6061 marine-grade aluminum tubes are defect-free, easy to polish, and can undergo anodizing to enhance corrosion resistance.

6082 Aluminum Alloy:

6082 aluminum alloy also offers good weldability and corrosion resistance. Widely used in the transportation and structural engineering industries, it has medium strength and can be heat-treated and strengthened.

It is suitable for manufacturing seamless aluminum tubes, structural profiles, and custom profiles. The mechanical properties of 6082 aluminum alloy are similar to those of 6061 aluminum alloy, but 6082 T6 aluminum tubes exhibit higher mechanical performance.

Besides shipbuilding, 6082 aluminum tubes also find extensive applications in the automotive and construction sectors.

Specifications of Marine-Grade Aluminum Round Tube

| Alloy | 6061, 6082 |

| Temper | T1, T5, T6, T6511 |

| Outer Diameter Range | 10 mm - 300 mm |

| Wall Thickness Range | 1 mm - 50 mm |

| Length | Standard length of 6 meters, customizable upon request |

| Surface Treatment | Anodizing, sandblasting, or coating protection |

| Tensile Strength | 290 - 340 MPa |

| Yield Strength | 240 - 310 MPa |

| Elongation | 8% - 12% |

| Density | 2.70 g/cm³ |

| Applications | Used for building T-tops, leaning posts, tuna towers, outrigger platforms, bow railings, and more. |

Advantages of 6061 6082 T6 Marine-Grade Aluminum Round Tubes

1. High Strength and Lightweight:

Compared to traditional steel, aluminum round tubes are much lighter, reducing the overall weight of the vessel while enhancing sailing performance.

2. Superior Corrosion Resistance:

With excellent resistance to salt spray and moisture corrosion in marine environments, 6061 and 6082 T6 aluminum tubes ensure prolonged service life.

3. Excellent Weldability and Machinability:

The aluminum round tubes exhibit outstanding welding performance and can undergo various complex machining processes, meeting diverse component design requirements.

4. High Fatigue Resistance:

The T6 heat treatment process enhances the fatigue resistance of the alloy, maintaining structural stability under long-term vibrations and load stress.

5. Cost-Effective:

Compared to high-performance stainless steel, 6061 and 6082 T6 aluminum round tubes offer more competitive pricing and lower maintenance costs.

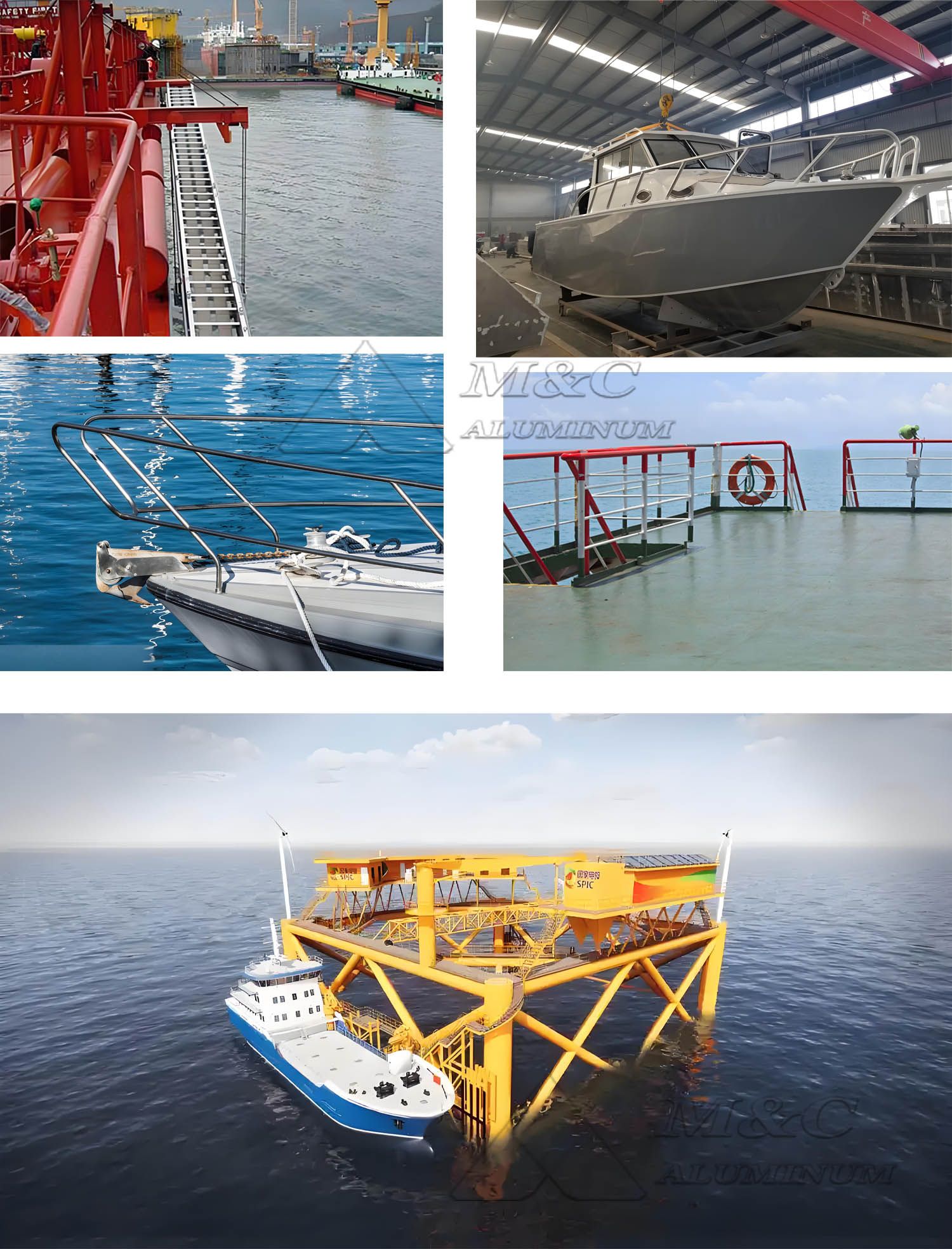

Application Fields

Marine-grade aluminum round tubes, due to their exceptional properties, are widely used in the following ship components:

Hull Frames and Deck Supports: 6061T6 aluminum tubes are lightweight and strong, reducing hull weight while improving fuel efficiency and sailing speed.

Ventilation and Exhaust Systems: Aluminum foil tubes are used for ship ventilation, being 40%-60% lighter than traditional galvanized steel tubes, lowering the ship's center of gravity and ensuring efficient ventilation.

Offshore Platform Supports: The 6082 aluminum tube is an ideal material for marine platform supports due to its corrosion resistance and high strength, ensuring long-term stable operation.

Special Equipment Protection: Copper-nickel coated conductive aluminum foil tubes are used in research vessels’ radar cabins to reduce electromagnetic interference and maintain good thermal conductivity.

Fireproof Isolation Systems: Double-layer aluminum foil composite tubes are used in luxury cruise ships as fireproof partitions, ensuring safety in case of fire.

Liquefied Natural Gas (LNG) Vessels: Aluminum round tubes are utilized in LNG storage tanks and cryogenic pipeline systems, ensuring flexibility and reliability at -50°C.

Standards for Marine Aluminum Round Tubes

1. Classification Society Certification Standards:

For marine applications, aluminum round tubes must meet the specific requirements of classification societies to ensure compliance with ship structure and safety standards. Certifications include DNV, LR, ABS, and others.

2. Dimensional and Surface Quality:

Standards specify the outer diameter, wall thickness, length, and other dimensional parameters, while also requiring the surface to be free from cracks, bubbles, inclusions, and other defects to ensure reliability during use.

3. Chemical Composition and Performance Requirements:

The chemical composition of marine aluminum round tubes must comply with GB/T 26006-2010 standards, with strict control over the content of major alloying elements such as Silicon (Si), Magnesium (Mg), Copper (Cu), and Zinc (Zn) to ensure corrosion resistance and mechanical performance.

Mechanical performance tests include tensile testing, bending testing, and hardness testing to verify that the strength and ductility meet the requirements.

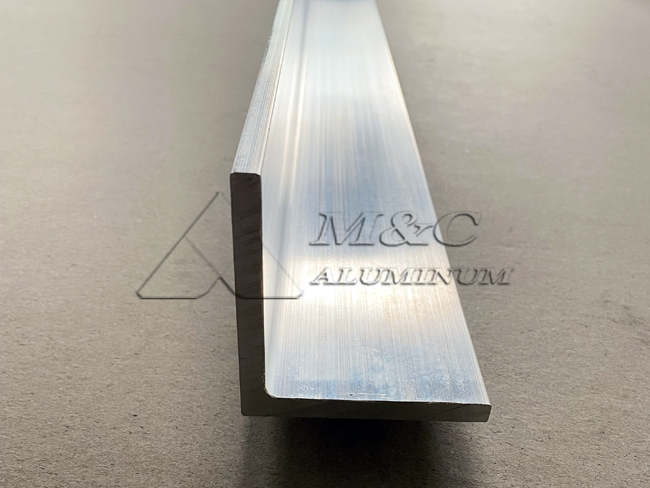

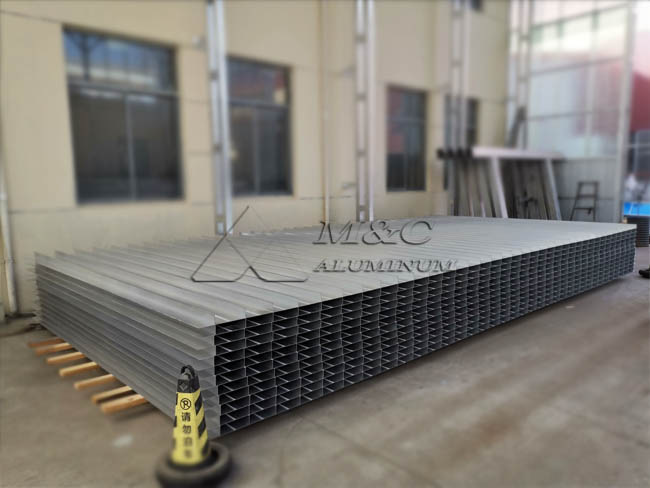

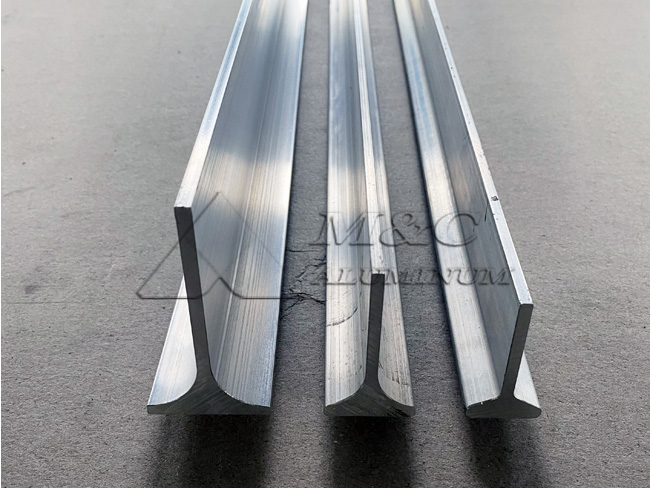

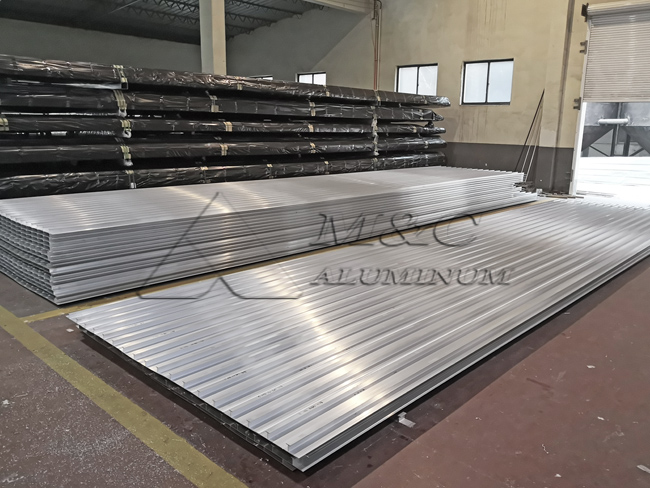

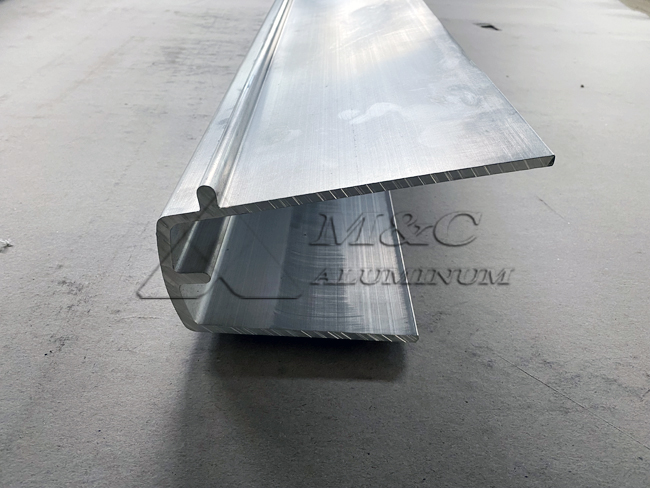

As a large-scale aluminum processing manufacturer for ships, MC Aluminum mainly produces various specifications of extruded aluminum profiles, including aluminum round tubes, angular aluminum, aluminum trough, I-type aluminum, T-type aluminum, aluminum square tubes, aluminum bars and other products. The aluminum alloy materials are: 6061, 6063, 6082, etc. The product variety is rich and the models are complete. It can be customized according to customer needs and exported to many countries and regions overseas. Samples are provided and after-sales service is perfect. Customers can order with confidence!