What is the 6061-T6 Aluminum Welded Concentric Reducer?

The 6061-T6 aluminum welded concentric reducer is a connecting pipe fitting made of 6061-T6 aluminum alloy, primarily used for transitioning between pipes of different diameters. Its “concentric” design ensures stable internal fluid flow, while the “T6” heat treatment process enhances its mechanical properties and corrosion resistance.

Once welded, 6061 butt-welded pipe fittings become an integral part of the system, providing leak-proof pipeline connections, increasing system strength, gradually changing the flow direction, optimizing space utilization, and minimizing the risk of erosion and corrosion caused by fluid turbulence. These fittings are available in various sizes and alloys, meeting multiple standards and specifications.

Advantages of Aluminum Alloy Concentric Reducers

1.Lightweight: Density is only one-third that of steel, significantly reducing equipment weight and improving energy efficiency.

2.High Strength: After T6 heat treatment, its strength is comparable to that of standard steel, meeting high-strength application requirements.

3.Corrosion Resistance: Excellent resistance to corrosion extends service life and reduces maintenance costs.

4.Aesthetic Appearance: The surface can be anodized or otherwise treated to enhance its visual appeal.

5.Weldability: Features excellent weldability; when using appropriate welding techniques such as TIG or MIG, it ensures high-strength and highly sealed connections, ensuring the safety and stability of the pipeline system.

Applications

Butt-weld fittings are widely used in industries that require durable welded connections for the transmission of liquids, gases, and chemicals while maximizing space utilization. These industries include marine, oil and gas, pulp and paper, pharmaceuticals, railways, food, and beverages.

Aerospace: Lightweight and high strength, suitable for aircraft fuel lines, hydraulic systems, etc.

Automotive Manufacturing: Extensively used in the cooling and exhaust systems of new energy vehicles.

Shipbuilding Industry: Excellent corrosion resistance, making it ideal for pipeline systems in marine environments.

Chemical and Pressure Vessels: High corrosion resistance, making it suitable for chemical transport pipelines.

High-End Engineering Pipelines: Ideal for food processing, pharmaceutical production, and other industries requiring high levels of cleanliness.

About MC Aluminum

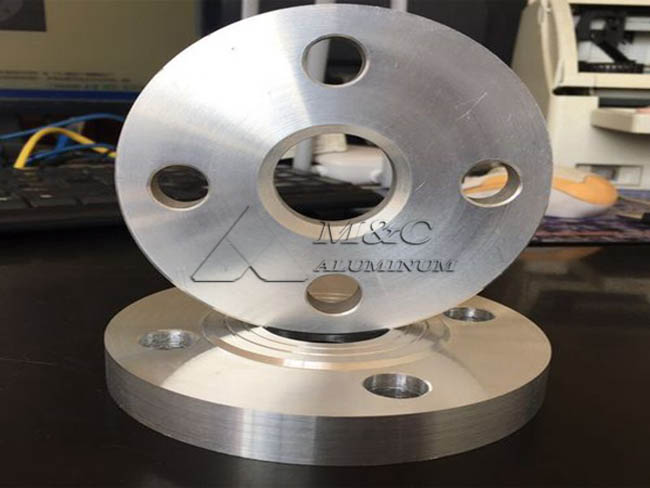

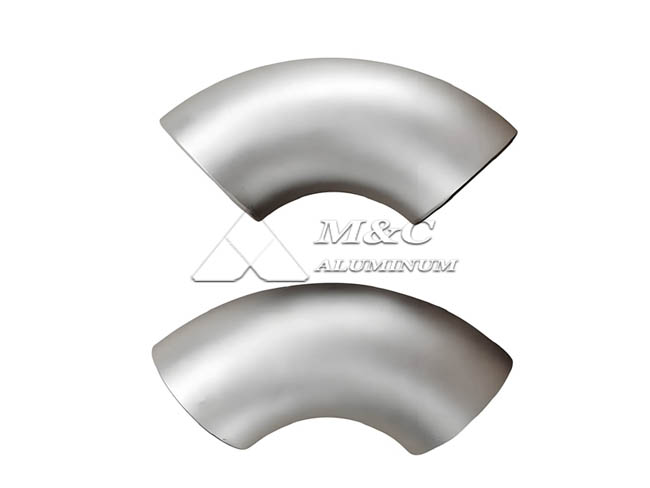

As a professional aluminum processing manufacturer, MC Aluminum specializes in producing marine-grade aluminum pipe fittings such as aluminum concentric reducers, aluminum pipe joints, aluminum eccentric reducers, aluminum flanges, aluminum 3D elbows, aluminum end caps, and more. Our products offer stable quality and can be customized according to customer requirements. We export globally, provide samples, and offer competitive pricing—ensuring reliable purchasing!