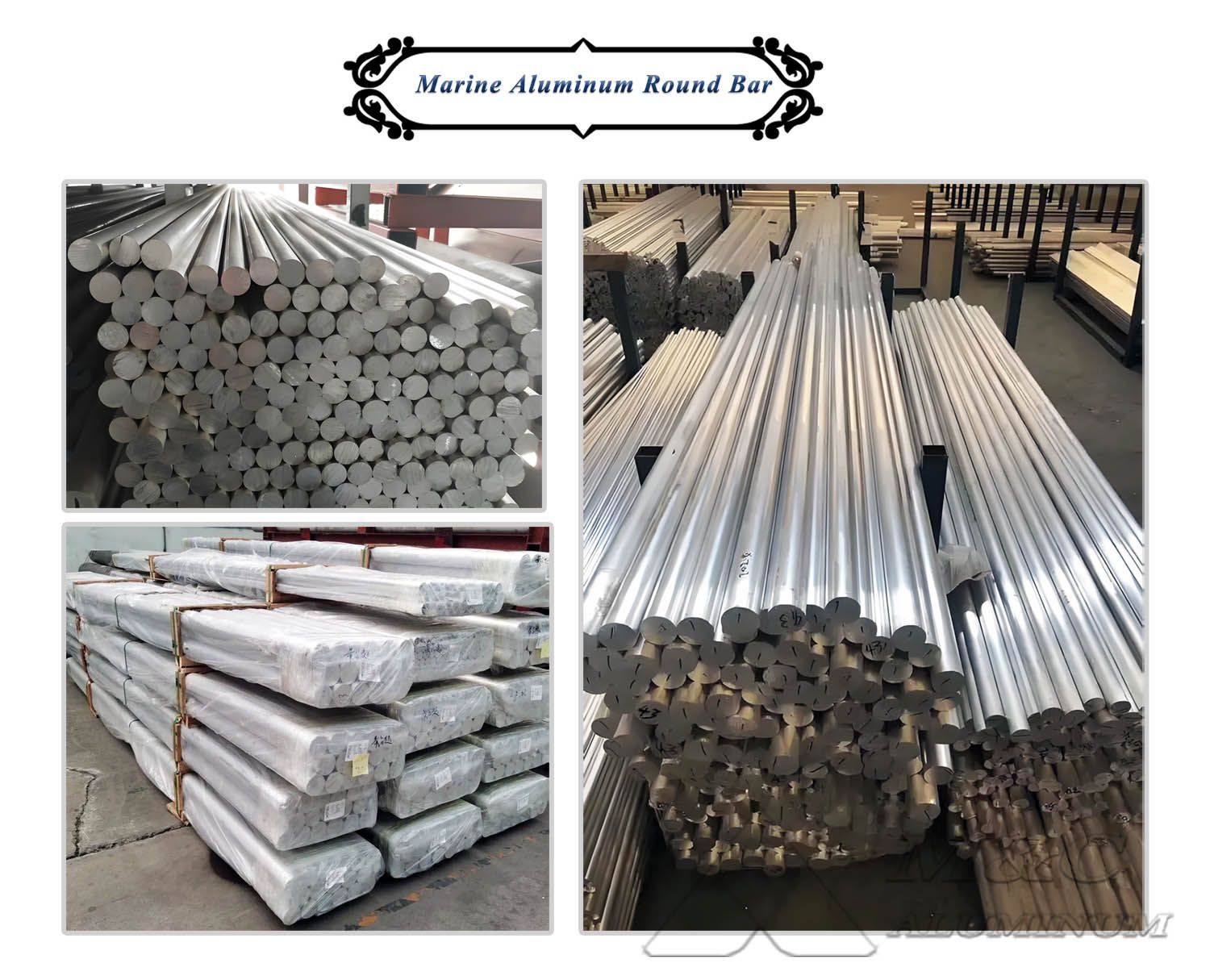

In shipbuilding, marine engineering, and high-end manufacturing industries, material selection directly determines product durability, safety, and performance. The 5-series marine-grade aluminum round bars produced by MC Aluminum, with their excellent corrosion resistance, high strength, and superior processing performance, have become the ideal choice for the shipbuilding and marine equipment industries.

Introduction to 5-Series Marine Aluminum Alloy for Extruded Aluminum Round Bars

The 5-series aluminum alloy belongs to the aluminum-magnesium alloy family, with magnesium (Mg) as the primary alloying element. Common marine aluminum alloy grades include 5052, 5083, 5456, 5754, and 5454.

5052 Aluminum Alloy:

Offers good corrosion resistance and medium strength, suitable for marine fuel tanks, bulkheads, decks, etc. It has excellent weldability and is ideal for medium-strength marine applications.5083 Aluminum Alloy:

Features high strength and outstanding seawater corrosion resistance, widely used in hull structures, marine engineering equipment, decks, and other high-strength ship components.5456 Aluminum Alloy:

Has higher strength than 5083, suitable for high-load hull structures, armored hulls, and high-stress environments, with superior fatigue resistance.5754 Aluminum Alloy:

A non-heat-treatable Al-Mg alloy with good corrosion resistance, weldability, formability, and surface treatment properties. It is used for ship interiors, cabins, bulkheads, and other lightweight applications.5454 Aluminum Alloy:

A rust-proof aluminum alloy known for its good rigidity, high strength, excellent fatigue resistance, superior corrosion resistance, and good weldability. It is mainly used in welded structures for marine facilities, pressure vessels, pipelines, etc.

Why Choose MC Aluminum’s 5-Series Marine Aluminum Round Bars?

To ensure the safety and reliability of 5-series marine-grade aluminum round bars, MC Aluminum’s products are certified by multiple international classification societies:

✔ China Classification Society (CCS)

✔ American Bureau of Shipping (ABS)

✔ Lloyd’s Register (LR, UK)

✔ DNV-GL (Norway-Germany Classification Society)

✔ Bureau Veritas (BV, France)

These certifications ensure that the aluminum alloy materials meet international shipbuilding standards, providing reliable material guarantees for shipbuilding projects.

Specifications of 5-Series Marine-Grade Aluminum Round Bars

| Alloys | 5052, 5083, 5456, 5754, 5454 |

| Temper | O-H112 |

| Maximum Diameter | 320mm |

| Length Options | 3000mm, 4000mm, 6000mm (customizable) |

| Surface Treatment | Anodizing, grinding, bright finish, polishing |

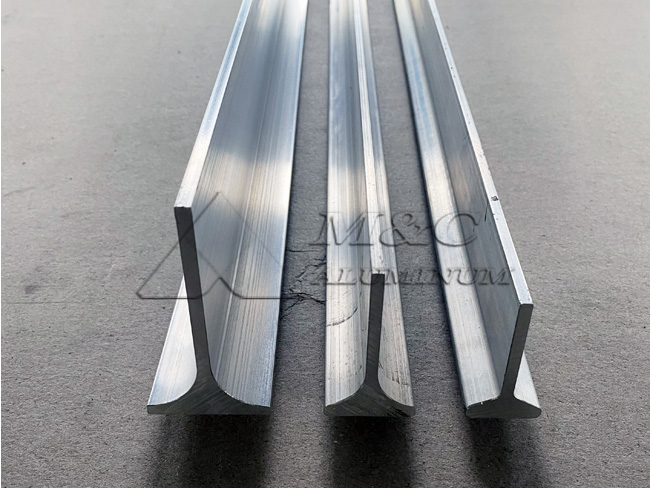

| Technology | Extrusion, cold drawing, forging |

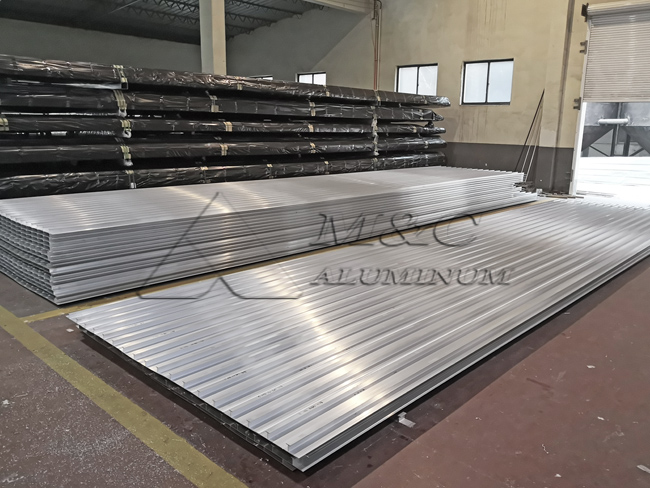

| Packaging | Wrapped in plastic bags and kraft paper, then secured on pallets |

Chemical Composition of 5052, 5083, 5456, 5754, and 5454 Solid Aluminum Round Bars (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Ohter:Total | Al |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remainder |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Remainder |

| 5456 | 0.25 | 0.4 | 0.1 | 0.5-1.0 | 4.7-5.5 | 0.05-0.2 | 0.25 | 0.20 | 0.05 | 0.15 | Remainder |

| 5454 | 0.25 | 0.4 | 0.1 | 0.5-1.0 | 2.4-3.0 | 0.05-0.2 | 0.25 | 0.2 | 0.05 | 0.15 | Remainder |

| 5754 | 0.4 | .04 | 0.1 | 0.5 | 2.6-3.6 | 0.3 | 0.2 | 0.15 | 0.05 | 0.15 | Remainder |

Mechanical Properties of 5-Series Marine-Grade Aluminum Bars

| Alloy | Temper | Thickness (mm) | Tensile Strength (N/mm²) | Yield Strength (N/mm²) | Elongation (%) |

| 5052 | H32 | 1.0-50 | 210-260 | 130-16 | ≥12 |

| 5083 | H116/H321 | 1.0-50 | 275-350 | 145-200 | ≥10 |

| 5456 | H116/H321 | 1.0-50 | 310-370 | 200-260 | ≥10 |

| 5754 | H111 | 1.0-50 | 190-260 | 80-130 | ≥12 |

| 5454 | H32 | 1.0-50 | 250-310 | 150-200 | ≥10 |

Product Advantages of 5-Series Marine-Grade Aluminum Bars

1.Strong Seawater Corrosion Resistance:

5-series aluminum round bars can withstand long-term exposure to marine environments without being easily corroded by salt mist, moisture, and chemicals, ensuring durability for ships and marine equipment.

2.High Strength and Lightweight:

Compared to traditional carbon steel materials, 5-series aluminum alloys have only one-third the density of steel, while maintaining high tensile strength. This reduces ship weight while improving navigation performance.

3.Excellent Weldability:

5-series aluminum alloys are particularly suitable for welding processes, meeting various shipbuilding requirements while improving production efficiency and welding quality.

4.Good Ductility and Processability:

Easily formed and machined to meet various shapes and specifications, making them suitable for complex hull structures.

5.Eco-Friendly and Recyclable:

5-series extruded aluminum round bars are environmentally friendly and recyclable, aligning with the trend of sustainable manufacturing.

Applications of Marine-Grade Aluminum Round Bars

Shipbuilding: Used for hull structures, decks, cabins, keels, and other key components.

Marine Engineering: Such as offshore drilling platforms, floating docks, and marine monitoring equipment.

Aerospace: Some high-end 5-series aluminum alloys are used in lightweight aerospace structural components.

Rail Transit: Applied in high-speed trains, subways, and light rail carriages.

Automotive Industry: Used in high-performance automotive chassis and body structures.