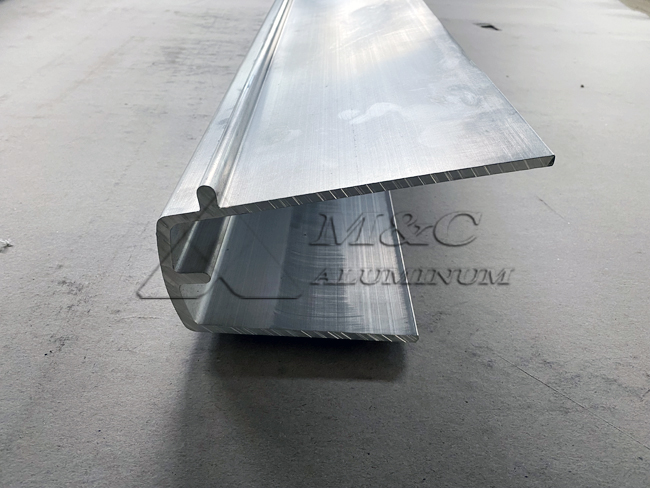

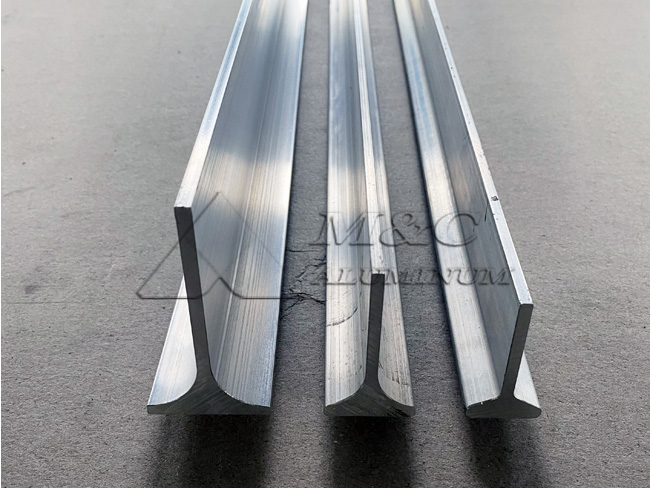

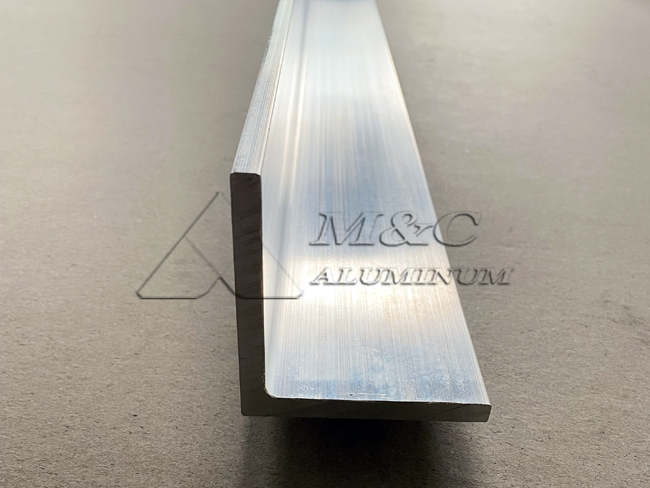

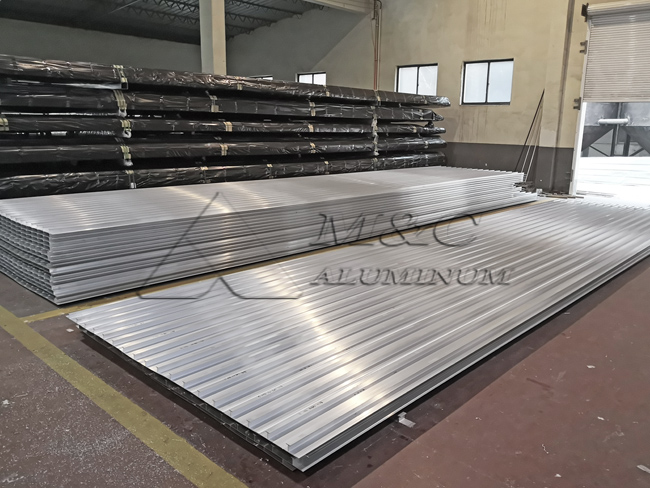

Friction stir welding(FSW), as an emerging welding technology, has gained widespread recognition and rapid adoption in the marine industry due to its stable, excellent joint performance and automated welding capabilities. MC Aluminum offers single, double, and multi-ribbed plates.

What is a marine aluminum ribbed plate?

A marine aluminum ribbed plate is a planar structure with multiple parallel lines running in one direction. The application of marine aluminum ribbed plates offers significant advantages in terms of structural performance, hull quality, and construction time, improving the performance of ship structures.

6082-T6 marine-grade aluminum ribs, with their high strength, corrosion resistance, and classification society certifications (ABS, CCS, LR, DNV, etc.), are an ideal steel replacement for marine engineering applications. They excel in lightweighting structures for high-speed craft, large yachts, and other marine applications.

Why choose 6082 T6 aluminum alloy for FSW panels?

6082 aluminum alloy belongs to the 6xxx series (aluminum-magnesium-silicon alloys) and is a heat-strengthened alloy. Its superior performance is primarily reflected in the following aspects:

High Strength: The T6 heat-treated state, characterized by solution heat treatment and artificial aging, significantly increases the yield strength and tensile strength of 6082 alloy, reaching medium-to-high strength levels, fully capable of meeting the load-bearing requirements of marine skeleton structures.

Good Corrosion Resistance: While its corrosion resistance is slightly inferior to that of 5xxx series alloys designed specifically for marine environments (such as 5083), 6082 alloy maintains excellent corrosion resistance in standard marine environments, effectively resisting corrosion from seawater and moisture.

Excellent Weldability: 6082 alloy exhibits excellent weldability. Appropriate welding processes (such as friction stir welding or inert gas shielded welding) can produce high-strength welds, ensuring a secure connection between the rib and the hull plating.

Advantages of Marine Aluminum Ribs

1. High Weld Strength and Reliability: FSW technology maintains material strength, resulting in welds that are nearly as strong as the parent material, avoiding the heat-affected zone (HAZ) issues associated with traditional fusion welding.

2. Excellent Fatigue Life: FSW welds are porosity- and crack-free, offering superior fatigue resistance and are suitable for hull structures subjected to long-term wave and vibration conditions.

3. Lightweight and Efficient: Utilizing the lightweight properties of aluminum alloy, the lightweight design reduces ship weight, improves speed and fuel efficiency, and increases payload.

4. Minimal Welding Distortion: FSW utilizes low heat input, maintains high dimensional accuracy and flatness, and reduces subsequent corrective work and manufacturing costs.

5. Efficient Production Process: Automated welding in a controlled environment improves production efficiency and shortens shipbuilding cycles. Simplified Assembly: Dimensionally precise and flat panels simplify assembly, reducing the need for highly skilled welders and saving labor costs.

6082 T6 Aluminum Alloy Extruded Ribs Product Information

Wall Thicknesses: 4mm, 5mm, 6mm

Common Specifications:

4+ IP 50, b=250mm, (6000×2000mm)

5+ IP 50, b=300mm, (6000×2100mm)

6+ IP 60, b=250mm, (6000×2000mm)

6+ IP 60, b=300mm, (6000×2100mm)

Customization available upon request

Applications

Superstructure: Frames and stiffeners (ribs) for the wheelhouse, cabin walls, and deckhouses.

Internal Structure: Floor supports, platforms, and equipment bases (e.g., generator and electronic equipment mounts). Reinforcement for various bulkheads and partitions.

Hull frames and ribs for small boats and workboats.

Comparison with 6061-T6 marine aluminum ribs

Strength: 6082-T6 boasts 10-18% higher tensile strength and approximately 15% higher hardness, making it more suitable for highly loaded structures.

Corrosion Resistance: Its lower copper content (0.15-0.4% vs. 0.2-0.6%) reduces the risk of intergranular corrosion, making it particularly suitable for marine environments.

Applications: 6082-T6 is primarily used in high-strength applications such as ships, bridges, and rail transit; 6061-T6 is more commonly used in electronics and building structures.

Original Source: https://www.marinealum.com/a/6082-t6-marine-grade-aluminum-ribbed-plate.html

Tag: FSW panel marine grade aluminum ribbed plate marine aluminum ribbed plate aluminum alloy ribbed plate 6082 T6 marine aluminum ribbed plate 6082 marine aluminum 6082-T6 marine aluminum plate extruded aluminum profile marine aluminum profile marine