In modern shipbuilding, lightweight materials, corrosion resistance, and structural strength are considered key design priorities. Aluminum profiles that have undergone T3, T4, T5, or T6 tempering and anodizing treatment offer outstanding comprehensive performance and are widely used in various ship structures, interior components, and functional parts—making them a critical material choice in marine equipment manufacturing.

What Are T3/T4/T5/T6 Tempers?

The temper of an aluminum alloy determines its mechanical and processing properties:

T3: Solution heat-treated and then cold worked; offers good ductility and moderate strength. Ideal for components requiring some flexibility, such as cabin walls and pipe connectors.

T4: Solution heat-treated and naturally aged. Combines good formability with moderate strength—suitable for parts that need shaping but don’t require high strength.

T5: Cooled after extrusion and artificially aged. Offers good dimensional stability and strength; widely used for finished structural parts.

T6: Solution heat-treated and then artificially aged, achieving the highest strength. Commonly seen in 6063-T6 aluminum plates, ideal for load-bearing structures like decks and hull components.

Advantages of Anodized Extruded Aluminum Profiles

Anodizing is an electrolytic process that forms a protective oxide layer on the aluminum surface. When applied to marine-grade aluminum profiles, it offers several advantages:

1.Enhanced Corrosion Resistance: Especially effective in salt spray and seawater environments, extending aluminum's service life.

2.Increased Surface Hardness: Resistant to scratches and mechanical damage—suitable for high-traffic or frequently handled areas.

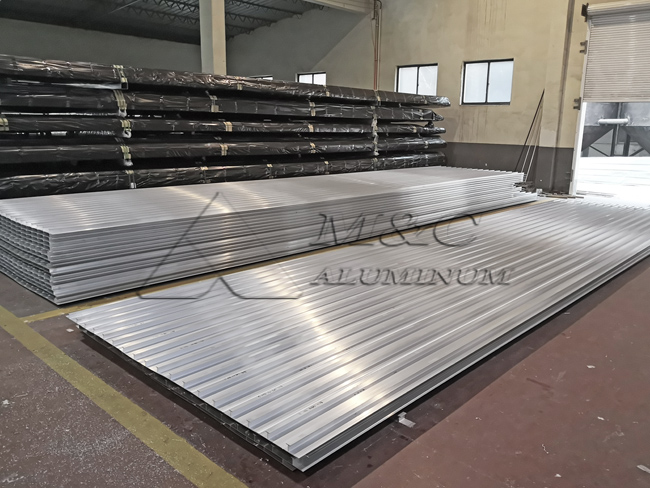

3.Welding Compatibility: Even after anodizing, T5/T6 profiles support friction stir welding (FSW), meeting the requirements for welding large ship panels (e.g., 26m × 3.5m panels).

4.Aesthetic Appearance: Surfaces can be finished in silver, black, gold, bronze, and more—improving interior and exterior vessel aesthetics.

5.Improved Coating Adhesion: The anodized layer enhances bonding with paints or adhesives, improving subsequent surface treatments.

Common Marine-Grade Aluminum Alloys and Their Applications

| Alloy | Temper | Features | Applications |

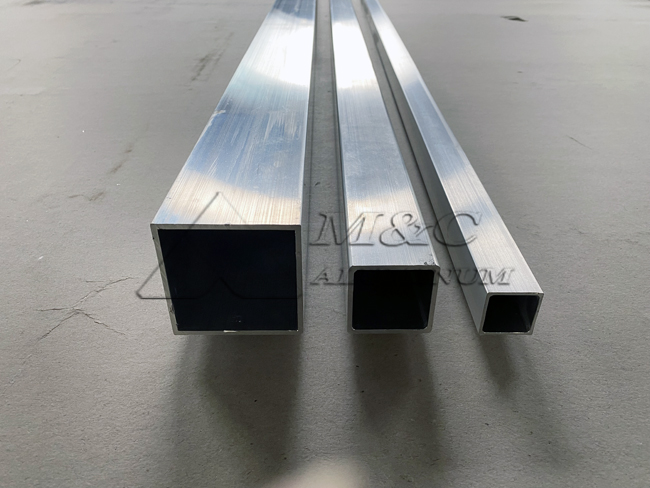

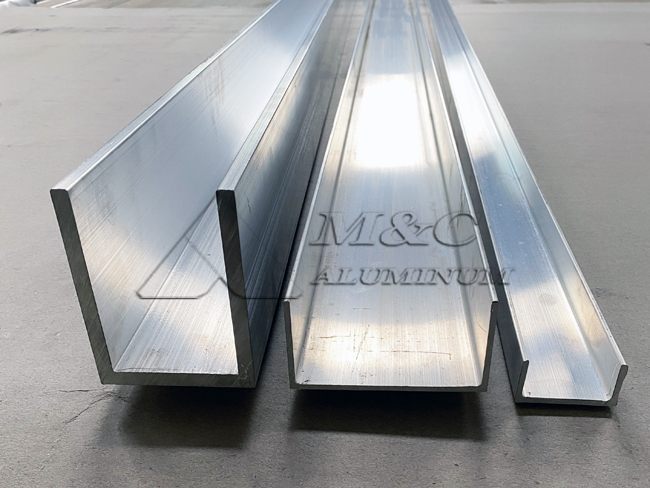

| 6061 | T5 / T6 | High strength, weldable, easy to machine | Ship railings, handrails, hatch frames, sliding tracks |

| 6082 | T6 | High strength and corrosion resistance, suitable for heavy loads | Hull frameworks, structural beams, platform supports |

| 5052 | H32 (similar to T4) | Excellent corrosion resistance and formability | Interior panels, cabin parts, ventilation covers |

| 5083 | H116 / T5 | Marine-grade with superior corrosion resistance | Hulls, deck plates, side shell structures |

Application Scenarios

Hull Framework: Used for keels, ribs, and longitudinal beams—reducing weight while maintaining structural integrity.

Deck Systems: Extruded profiles used to build non-slip, corrosion-resistant working platforms.

Cabin Structures: Ideal for cabin walls, ceilings, door/window frames—lightweight and easy to install.

Equipment Mounting & Rails: Standard profiles for navigation equipment, lifeboat mounts, and electrical systems.

Aluminum profiles in T3, T4, T5, and T6 tempers with anodized surfaces combine strength, corrosion resistance, visual appeal, and workability—making them one of the most ideal structural and decorative materials in modern marine design. Whether used in offshore engineering vessels, high-speed boats, yachts, or new-energy fishing boats, they deliver long-lasting, durable performance that supports the industry's goals for lightweighting, safety, and aesthetics.

About MC Aluminum

MC Aluminum is a large-scale aluminum processing manufacturer specializing in marine-grade aluminum plates, aluminum profiles for ships, FSW panels, and aluminum-steel composite plates. We offer a wide selection of marine-grade alloys including 5083, 5086, 5052, 5059, 5754, 5456, 6061, 6063, 6082, with customizable dimensions. Our products are exported worldwide and trusted by customers for their reliability. We provide samples, fast delivery, and after-sales assurance—making us a dependable partner for your marine aluminum needs.