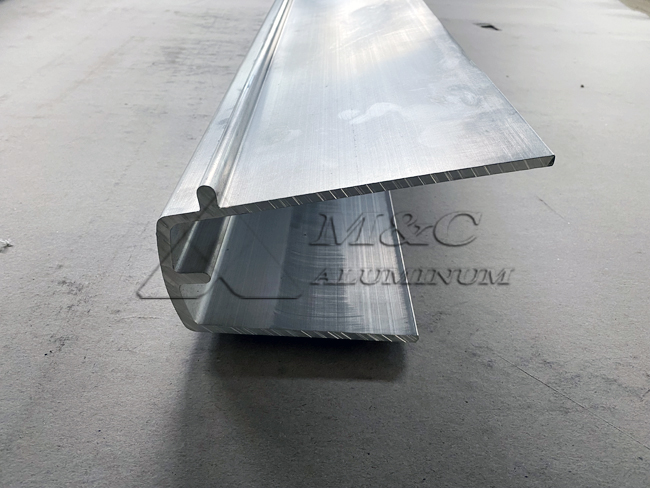

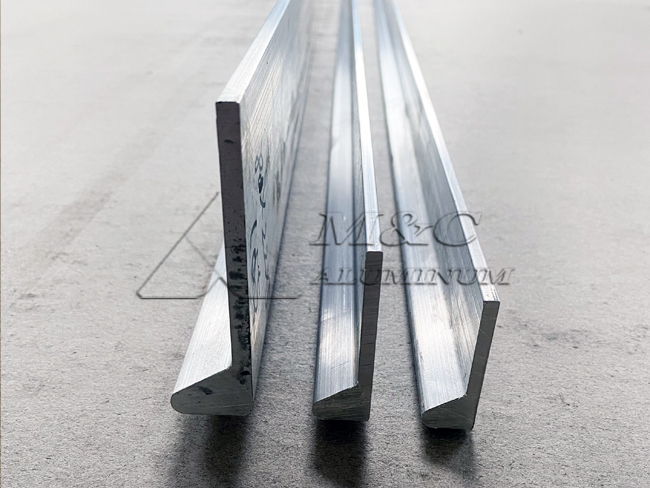

Aluminum profiles for ship railings are a type of aluminum material specially designed for ship structures. They are lightweight, corrosion-resistant, high-strength, easy to process and install.

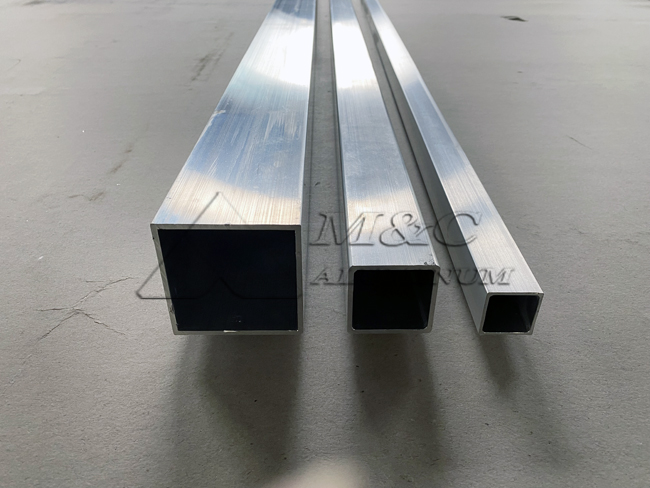

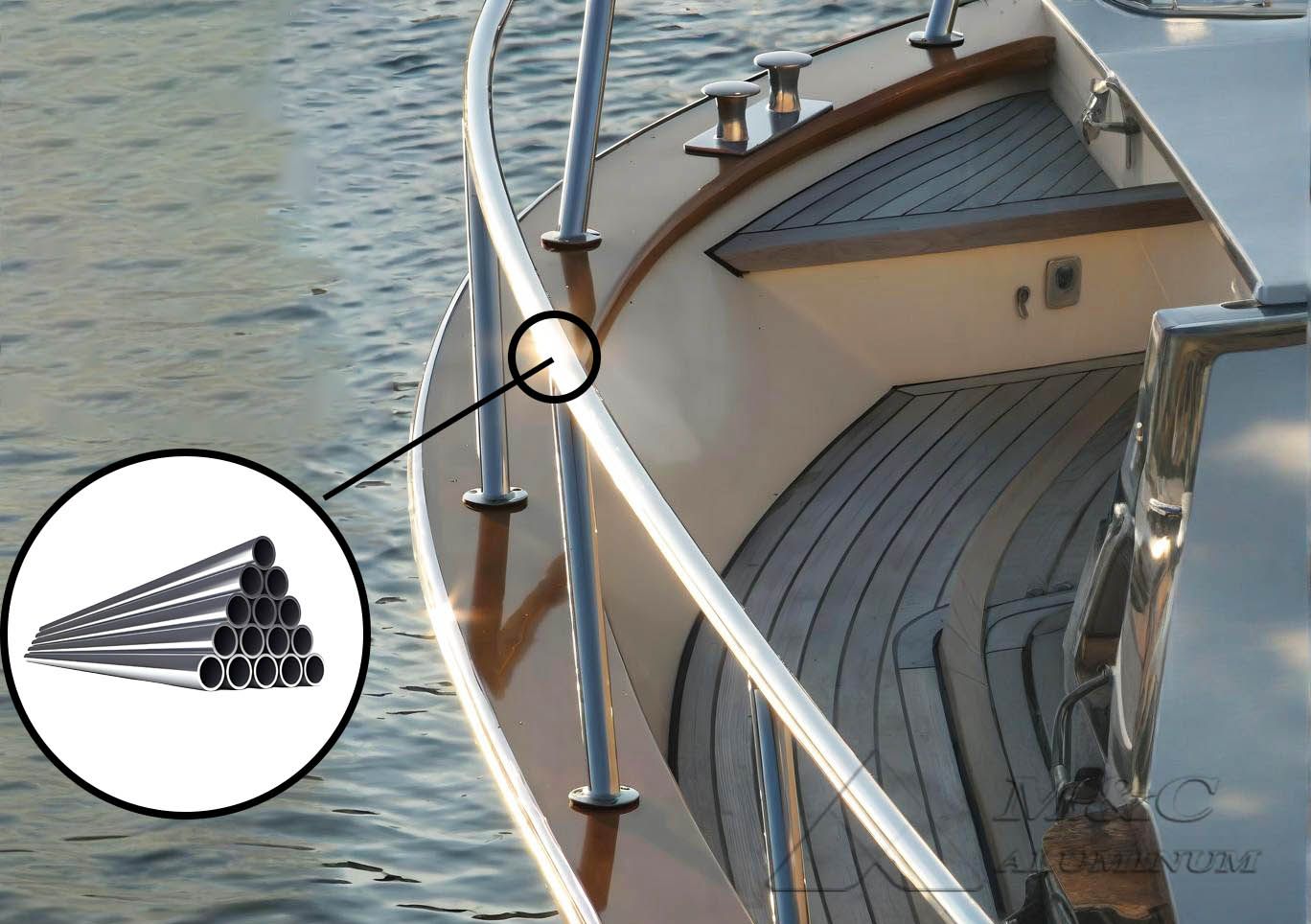

Anodized marine grade aluminum profiles handrails usually use 6061, 6063, 6082, 5083 aluminum alloy industrial profiles. The type of aluminum profile is aluminum tube, with classic shape, simple and generous, widely used in yachts, passenger ships, cargo ships, external deck railings, etc., providing a good grip.

Features of aluminum tubes for ship railings:

1. Lightweight and high strength: Aluminum profiles have low density but high strength, which reduces the overall weight of the ship and improves navigation efficiency and load-bearing capacity.

2. Strong corrosion resistance: Aluminum alloy has excellent corrosion resistance, especially in marine environments, can effectively resist seawater erosion and extend service life.

3. Beautiful: The surface of aluminum profiles can be anodized, sprayed and other treatments, showing a variety of colors and textures, improving the beauty of the ship.

4. Easy to process: Aluminum profiles are easy to cut, weld, bend and other processing, and can meet the design requirements of various complex shapes.

5. Convenient installation: Aluminum profiles have various connection methods, easy and quick installation, reducing construction costs and time.

6. Low maintenance cost: Aluminum profiles are easy to maintain, do not require frequent maintenance, and reduce long-term use costs.

Marine aluminum tube specifications:

| Alloy | 6061, 6063, 6082, 5083, etc |

| Temper | T5, T6,H116 |

| Size | Φ30mm × 2mm Φ35mm × 5mm Φ45mm × 4mm Φ50mm × 4mm Φ60mm × 3mm Φ70mm × 6mm Φ80mm × 5mm ,Customizable |

| Certificate | CCS, BVLR, ABS, DNV-GL |

| Application | Suitable for main handrails and railing frames |

Surface treatment of marine grade aluminum profiles

Surface treatment of marine aluminum tubes can not only improve the aesthetics, but also enhance the anti-corrosion performance. Common surface treatment methods include:

Anodizing: Enhances anti-oxidation and corrosion resistance. Common colors include silver, black, bronze, etc.

Powder coating: Provides a richer range of color options and improves weather resistance and wear resistance.

Electrophoresis Coating: Smooth surface, excellent anti-corrosion ability, suitable for high-end ship handrail applications.

Sandblasting + oxidation: Remove surface defects, increase texture, prevent fingerprints and scratches.

Why choose us?

1. The marine grade aluminum profiles produced are in compliance with the certification of classification societies such as CCS, DNV, ABS, etc.

2. Aluminum alloy has sufficient corrosion resistance.

3. The aluminum tube has no obvious scratches, cracks, pits, inclusions, oxidation spots and other defects.

4. If it is a welded aluminum tube (TIG/MIG welding), the weld must be uniform, without cracks, pores, slag inclusions, unfused defects, etc., to ensure that the welding area does not affect the overall strength and corrosion resistance.