Meeting the Demands of Modern Shipbuilding with Ultra-Wide Plates

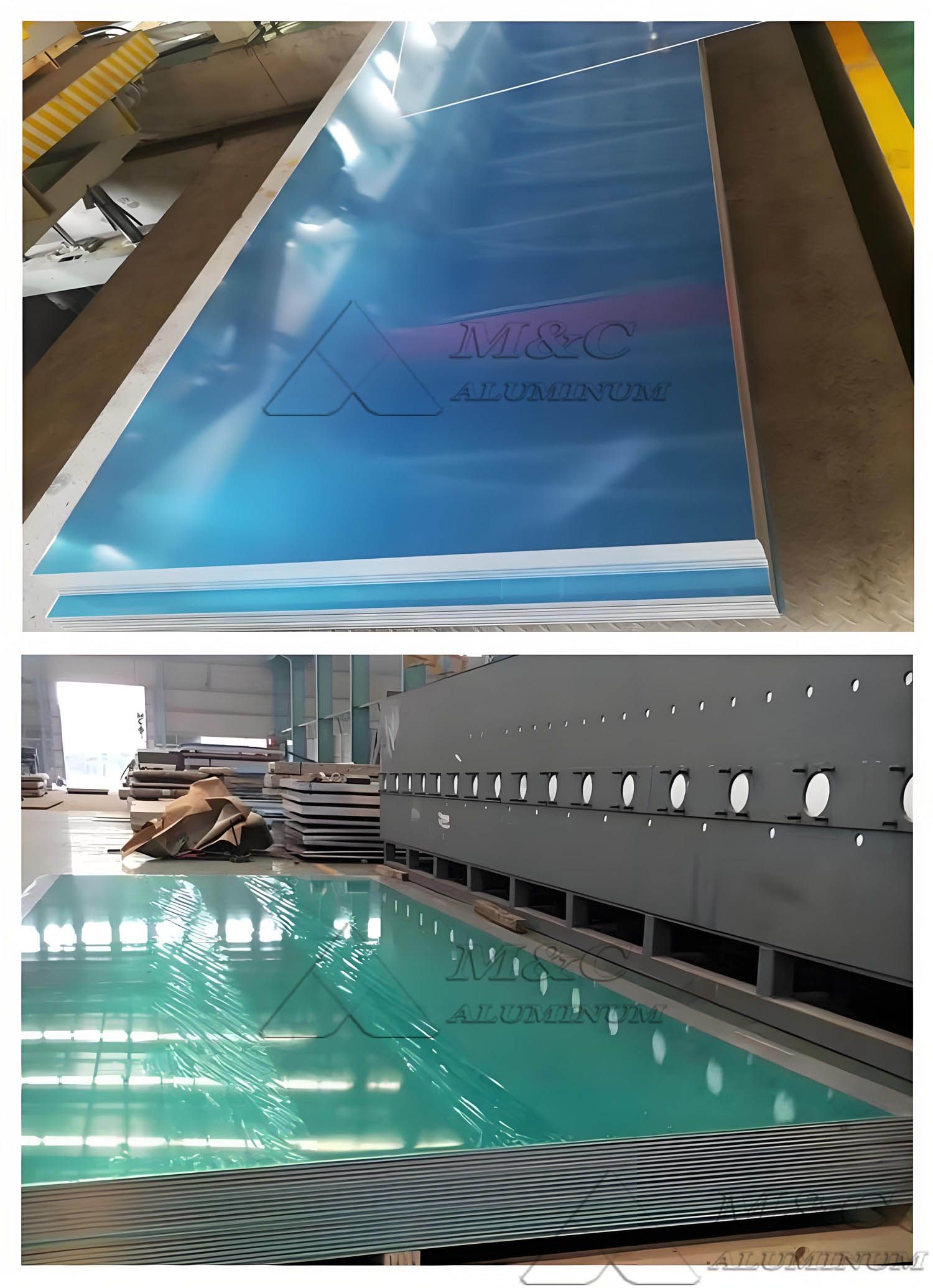

As shipbuilding moves toward larger and more integrated structures, traditional aluminum plates with widths of 1200mm–1600mm are no longer sufficient to meet design demands for single-sheet application, fewer welds, and cost reduction. The introduction of the 2600mm ultra-wide aluminum plate significantly reduces the number of joints, simplifies welding operations, and enhances the overall structural integrity and watertightness of the vessel.

5083 Marine Aluminum Plate: The Ideal Material for Shipbuilding

5083 aluminum is a classic magnesium-aluminum-silicon alloy known for its excellent corrosion resistance and anti-rust properties, making it the top choice for marine applications. It is especially well-suited for the underwater parts of ship hulls, which require materials capable of withstanding long-term seawater exposure.

Among the available temper options, 5083-H116 and 5083-H321 offer superior corrosion resistance and post-weld stability, making them more suitable than H111 and H112 for demanding marine environments. These tempers are widely used in critical areas such as hull bottoms and below-waterline side shells.

Common Tempers of 5083 Marine Plate:

Specifications

| Alloy | 5083 |

| Tempers | H116 / H321 / H112 (Others available) |

| Thickness | 3.0mm – 50.0mm (Standard: 6mm, 8mm, 10mm, 12mm) |

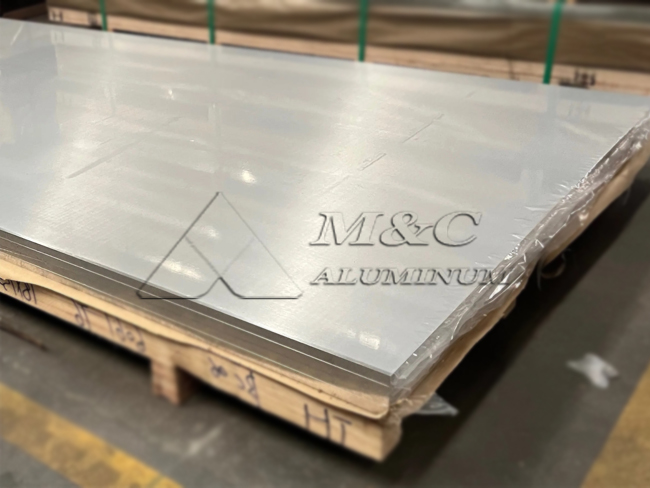

| Width | 1000mm – 2600mm (Ultra-wide customization supported) |

| Length | 2000mm – 16000mm (Custom lengths available) |

| Density | 2.66 g/cm³ |

| Surface Finish | Mill finish, brushed, anodized, or customized |

| Certifications | CCS, DNV, NK, ABS, BV, LR, KR |

| Origin | Zhengzhou, Henan, China |

| MOQ | 1–3 tons |

2600mm Ultra-Wide: A Leap in Shipbuilding Efficiency

Traditionally, shipbuilding relies on narrow aluminum sheets that require extensive welding. The 2600mm ultra-wide format brings several critical advantages:

Fewer Welds: Reduces the number of joints and weld seams, minimizing structural weak points and potential defects.

Higher Productivity: Less welding leads to faster construction times and lower labor costs. Large sheets also improve automation efficiency for cutting and forming.

Improved Structural Integrity: Fewer seams lead to better structural continuity, reducing stress concentrations and enhancing overall fatigue resistance and strength.

New Possibilities for Modern Marine Design

The 2600mm 5083-H112 ultra-wide marine aluminum plate is ideal for:

High-speed vessels, fishing boats, and yachts

Offshore wind platforms, pontoons, and workboats

LNG ships, cargo vessels, coast guard ships, and military vessels

As a professional manufacturer of marine-grade aluminum plates, MC Aluminum strictly controls production processes, from alloy composition optimization to casting, homogenization, and rolling. Our 5083 plates deliver performance on par with international standards and are exported to multiple countries worldwide.

We offer samples, support OEM customization, and provide direct factory sales. New and existing customers are welcome to visit our facility for inspection and cooperation.