Ship aluminum profile refers to aluminum alloy profile used to manufacture ships. It has the advantages of high strength, corrosion resistance, and light weight. It is used to build various types of ships, including cargo ships, tankers, passenger ships, warships, etc., and is widely used in hull structures, decks, propulsion systems and other parts.

Compared with traditional steel, extruded aluminum profiles have better corrosion resistance and lighter weight, which can reduce the dead weight of the hull and increase the ship's load capacity and sailing speed. Therefore, marine aluminum profiles are increasingly favored in shipbuilding and have become one of the mainstream materials in today's shipbuilding industry.

The specifications and models of ship aluminum profiles mainly include the following

5 series aluminum alloy profiles

Common models are 5052, 5083, 5086, 5454, etc. The main component is magnesium. It has good corrosion resistance, weldability and medium strength.

5083 marine aluminum alloy is widely used in shipbuilding, and is used for local parts such as hull bulkheads and hull belly plates; 5086 marine aluminum plates are mainly used for ship bottom plates, and can also be used as materials for other local parts; 5454 marine aluminum alloy is often used in hull bulkheads, chemical storage tanks, hull tanks and other fields.

6 series aluminum alloy profiles

Common models include 6061, 6063, 6082, etc. The main components are magnesium and silicon, with high strength and good processing performance.

6061 marine aluminum alloy is widely used in the shipbuilding industry, mainly used in hulls, bridges and other parts, and can also be used for accessories manufacturing; 6082 marine aluminum alloy is mainly used for hull belly plates, bulkheads, etc., as well as accessories, vertical poles, etc.

Specific specifications for reference

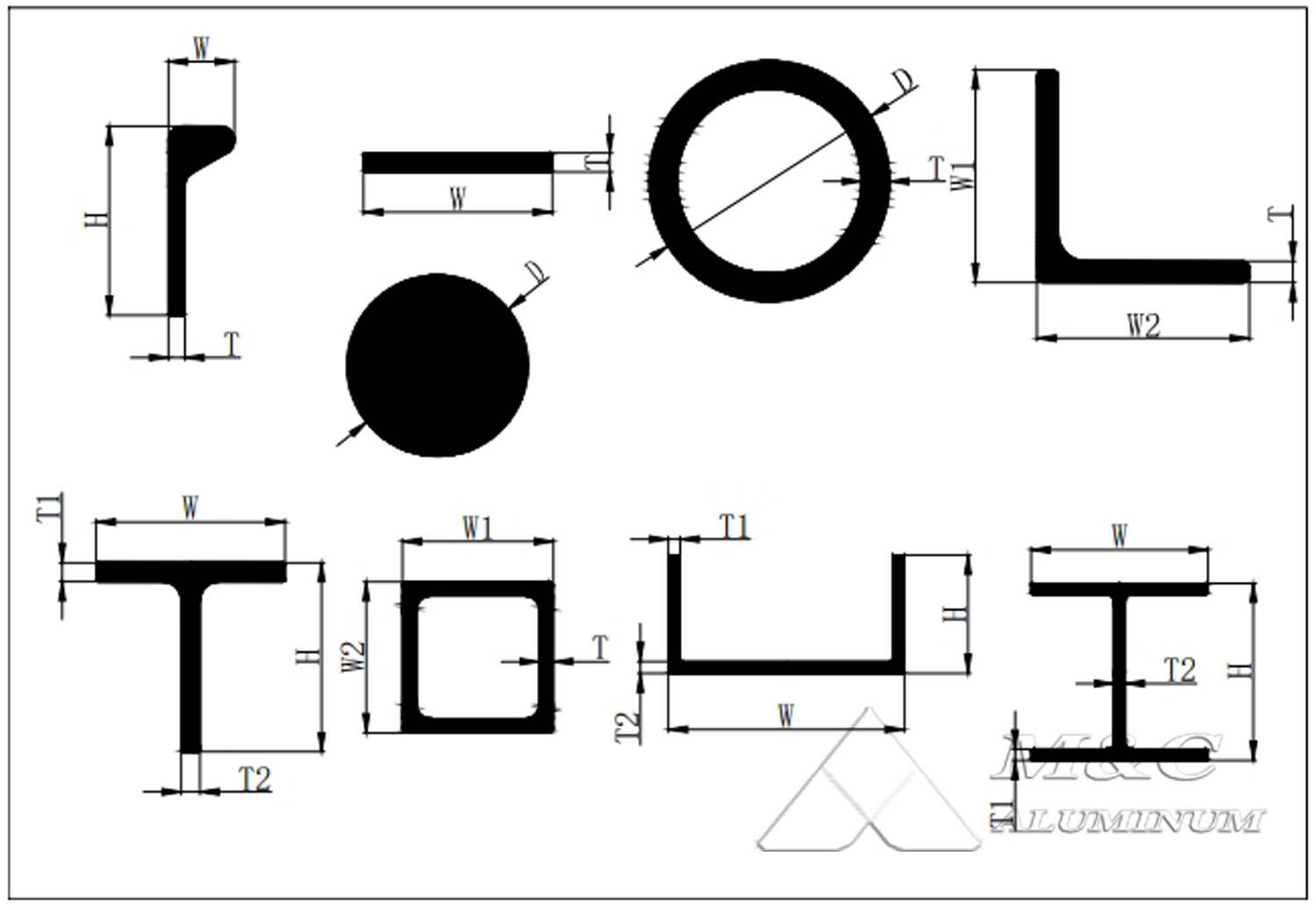

Pipe diameter: Φ10mm, Φ50mm, Φ100mm, Φ200mm, etc.

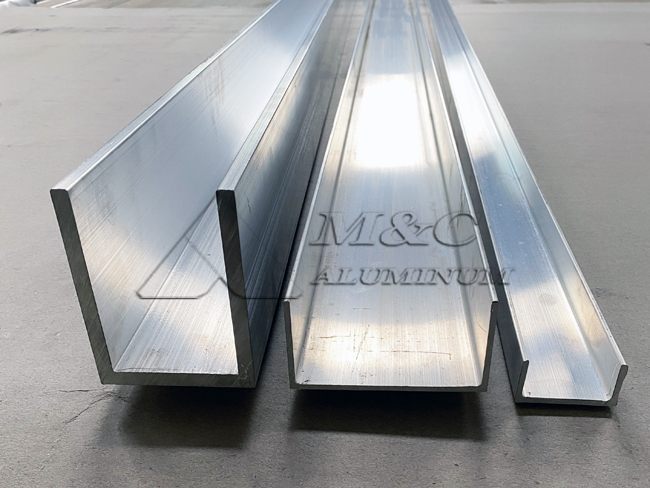

Angle aluminum specifications: 20×20mm, 50×50mm, 100×100mm, etc.

T profile specifications: width 50mm-200mm, thickness 3mm-10mm

H profile specifications: width 100mm-300mm, height 50mm-200mm

Ship aluminum profile processing technology

1. Profile selection: First, choose high-quality aluminum profiles that meet ship construction standards. Usually choose high-strength, corrosion-resistant, and lightweight aluminum profiles to meet the needs of ship construction.

2. Profile cutting: According to the design requirements of the ship, the aluminum profile is cut, usually using a CNC cutting machine or sawing machine to ensure that the size and shape of the profile meet the design requirements.

3. Profile forming: The aluminum profile is formed through cold and hot extrusion processes, usually using CNC machine tools for precise forming to ensure the accuracy and surface quality of the profile.

4. Profile welding: The aluminum profiles of different parts are welded, usually using MIG welding, TIG welding, laser welding and other welding processes to ensure the quality and strength of the welded joints.

5. Profile surface treatment: The formed aluminum profiles are surface treated, including anodizing, spraying, electrophoresis and other processes to improve the corrosion resistance and aesthetics of the profile.

6. Profile assembly: The aluminum profiles of each component are assembled, usually using screws, riveting and other methods to ensure the stability and sealing of the ship structure.

7. Profile inspection: Strict quality inspection is carried out on the processed aluminum profiles, including size, shape, surface quality, strength of welded joints, etc., to ensure that the profiles meet the shipbuilding standards.

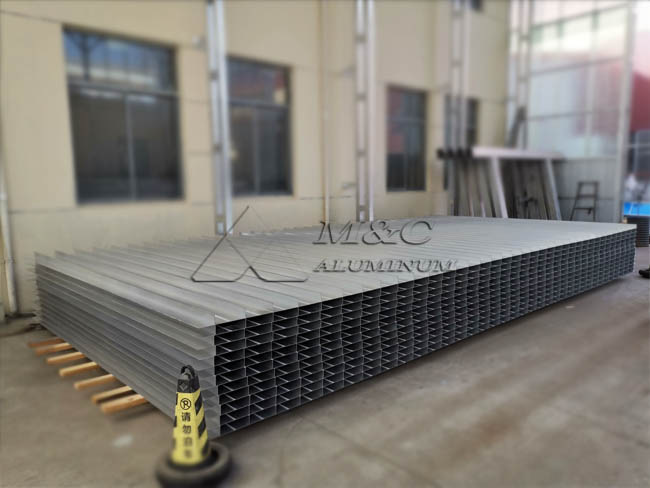

8. Profile packaging: Finally, the processed aluminum profiles are packaged, usually in a moisture-proof and shock-proof packaging method to ensure that the profiles are not damaged during transportation.

As an aluminum processing manufacturer, MC Aluminum has a stock of marine aluminum plates and aluminum profiles certified by classification societies such as CCS, DNV, and ABS, including 5000 series and 6000 series aluminum profiles for shipbuilding. The marine aluminum profile inventory also includes some special specifications of profiles, such as T-type, L-type, angle steel, square tube, etc., to meet the needs of different shipbuilding projects. These profiles have been precisely processed and inspected to ensure that their quality and performance meet international standards and can meet the requirements of various shipbuilding projects.