Aluminum sheet coils used for ships and yachts are often made of aluminum alloy materials with excellent corrosion resistance, high strength and processability. Marine-grade aluminum sheets are suitable for use in marine environments because they are resistant to salt water corrosion, are not prone to rust, and are lightweight, helping to reduce the overall weight of the hull and improve fuel efficiency and stability.

Aluminum alloy models for ships/yachts

1.5052 aluminum alloy

Features: 5052 aluminum alloy has good corrosion resistance and medium strength, and is suitable for ship structures that require rust prevention.

Application: small yachts, hull structures, decks, etc.

2. 5083 aluminum alloy

Features: 5083 aluminum alloy is known for its high strength and excellent corrosion resistance, and is especially suitable for use in harsh marine environments.

Application: large and medium-sized hull outer panels, cabin partitions, bottom sheets, etc.

3. 6061 aluminum alloy

Features: 6061 aluminum alloy has high mechanical properties, good processability, and excellent welding performance.

Application: Structural components such as ship decks, hatches, frames, etc.

4. 5754 aluminum alloy

Features: 5754 aluminum alloy has excellent corrosion resistance, moderate strength, and good formability and weldability.

Application: Suitable for internal and external structural parts in marine environments.

5. 6063 aluminum alloy

Features: 6063 aluminum alloy is usually used for parts that require high corrosion resistance and beautiful surface, and its strength is slightly lower than 6061.

Application: decorative parts, railings, handrails, etc.

Summary of advantages of marine aluminum coils

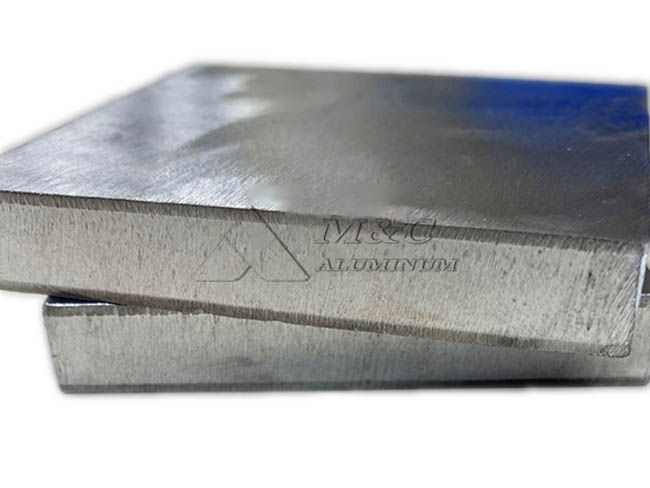

1. Light weight and high strength: low density and high strength, reducing the weight of the hull, improving fuel efficiency and reducing operating costs.

2. Strong corrosion resistance: Special anti-corrosion treatment effectively resists seawater corrosion and oxidation, prolongs service life and reduces maintenance frequency.

3. Good processing performance: easy to cut, bend and weld, ensuring design accuracy and stability.

4. Good weldability: reliable connection with other metals or aluminum alloys. After welding, the structure has high strength and is not easy to crack.

5. Good fatigue resistance: long-term use maintains fatigue resistance and ensures stable navigation in bad weather.

6. High aesthetics: The surface is smooth and easy to handle, which improves the beauty of the hull and enhances market competitiveness.

7. Environmental protection: Recyclable materials meet environmental protection requirements and reduce resource waste.