As the global shipbuilding industry increasingly demands lightweight, corrosion-resistant, and environmentally friendly solutions, aluminum alloys are playing a more prominent role in vessel construction. In particular, 5083 and 5086 marine-grade aluminum plates have become top choices for modern hulls, decks, and cabin structures, thanks to their excellent corrosion resistance, good weldability, and high strength-to-weight ratio.

The Value of Aluminum in Shipbuilding

While traditional steel hulls have high strength, they are heavy and prone to corrosion, requiring frequent derusting and repainting. In contrast, aluminum alloy hulls offer:

Lightweight: Reduces vessel weight, improving speed and fuel efficiency

Excellent corrosion resistance: Especially suitable for seawater environments

Good formability and weldability: Ideal for complex structures and modular construction

Low maintenance costs and long service life

Low-temperature toughness: Aluminum alloys remain ductile and crack-resistant even in cold sea conditions

Among many options, 5000-series marine aluminum alloys are the mainstream choice in shipbuilding thanks to their outstanding resistance to seawater corrosion.

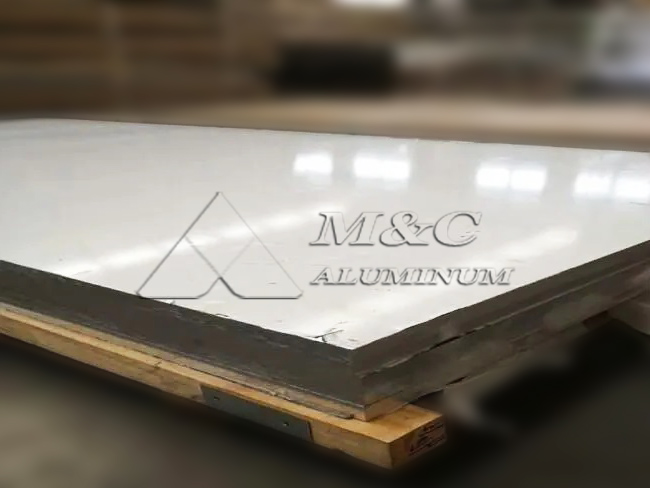

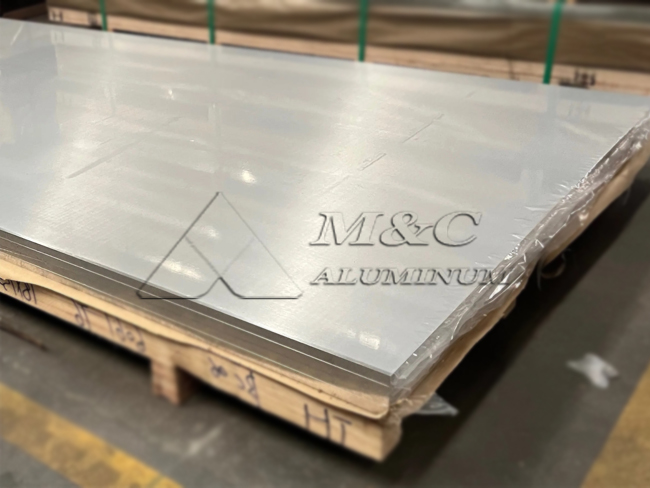

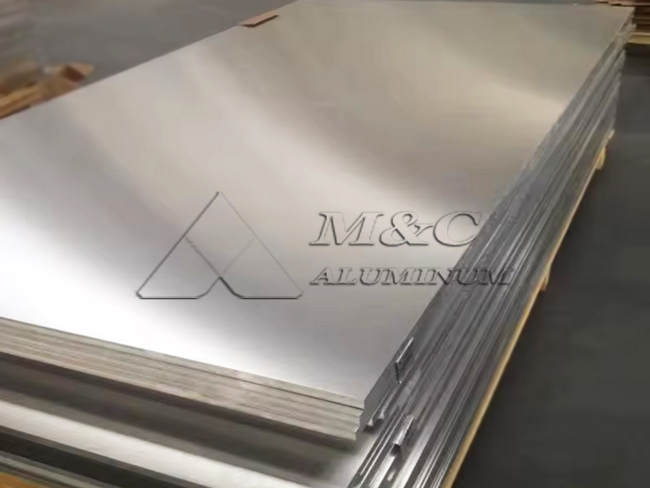

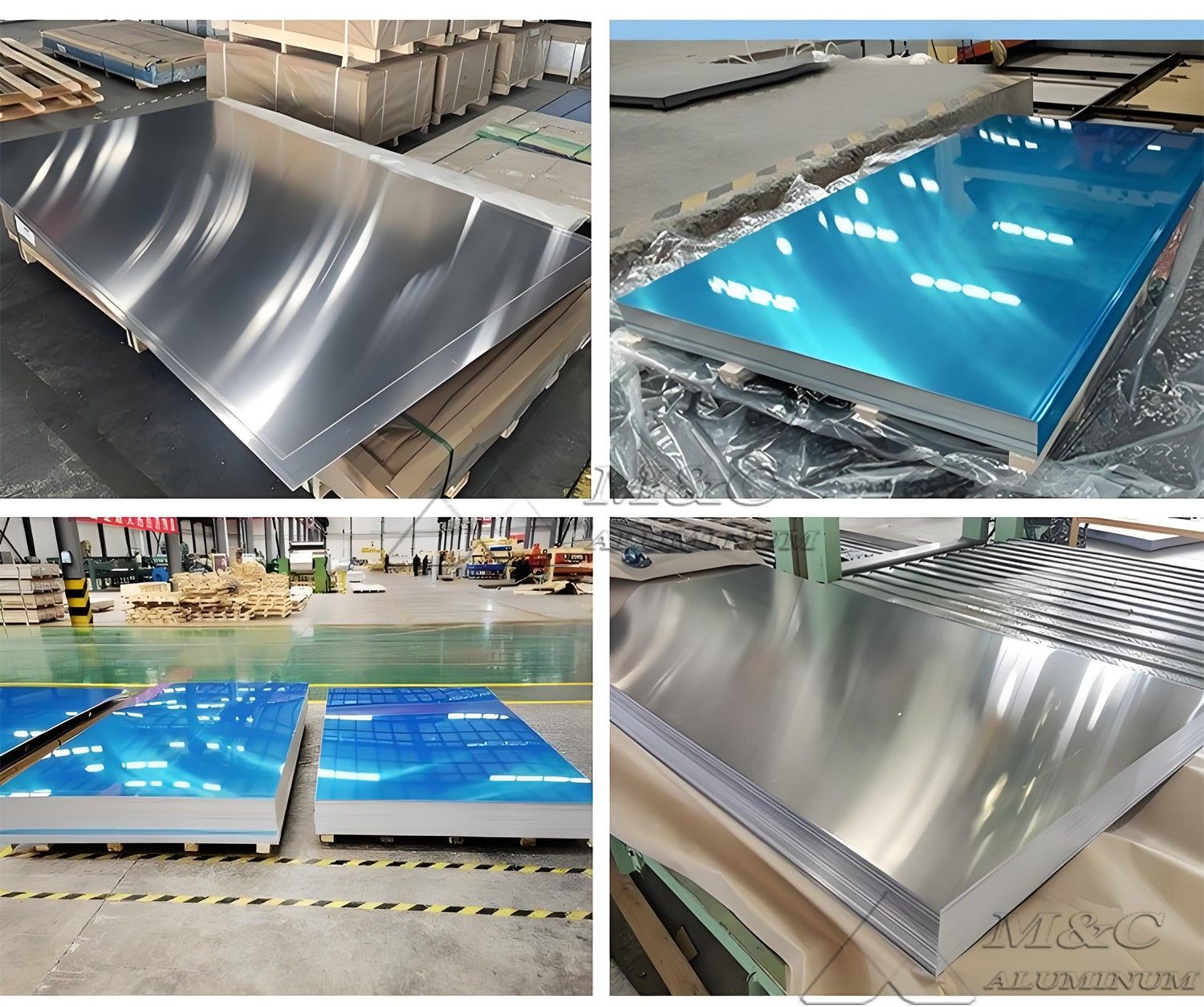

Basic Information for Marine-Grade Aluminum Plates

| Alloys | 5083,5086 |

| Temper | H116, H321, O, etc. |

| Thickness | 2-50 mm |

| Width | ≤2500 mm |

| Length | ≤12000 mm |

| Surface | Flat plate or embossed anti-slip pattern |

| Processing services | Cutting, bending, pre-forming, anodizing |

| Certification standards | ABS, DNV, BV, CCS, and other classification societies |

| Packaging | Standard seaworthy packaging |

| OEM/ODM | Accepted |

| MOQ | 1–3 tons |

Mechanical Properties

| Item | 5083 H116 | 5086 H116 |

| Tensile Strength | 275-350 MPa | 240-290 MPa |

| Yield Strength | ≥215 MPa | ≥190 MPa |

| Elongation | 10–12% | 12–14% |

| Density | approx. 2.66 g/cm³ | approx. 2.66 g/cm³ |

How to Choose Between 5083 and 5086 for Shipbuilding

Selecting 5083 or 5086 aluminum plate in ship construction primarily depends on your specific application needs:

1. If your project demands very high strength, for parts that must bear greater loads and stress (such as the main structural components of large vessels), 5083 aluminum plate is typically the better choice.

2. If your project places a premium on weldability or has moderate strength requirements, 5086 aluminum plate may be preferable, thanks to its excellent weld performance and often lower cost.

Both alloys undergo strict marine-grade certifications (such as CCS, DNV, LR, ABS, etc.) to ensure their reliability and durability in harsh marine environments. Together, they offer modern shipbuilding lightweight, corrosion-resistant, high-performance solutions.

MC Aluminum is a professional manufacturer of marine aluminum plates, producing 5-series and 6-series marine-grade aluminum alloy plates, including 5083, 5059, 5456, 6061, and 6082. All products are certified to marine standards, meeting the needs of shipbuilding customers. Our products are exported overseas, samples are available, and we offer factory-direct sales with competitive pricing for worry-free ordering.