What is marine aluminum profile?

Marine aluminum profile is an aluminum alloy profile specially designed for ships and marine environments. It is widely used in hull structures, decks, cabins and other shipboard components. The reason why this type of aluminum profile is popular is mainly because it has the characteristics of light weight, high strength, corrosion resistance, etc., especially suitable for long-term exposure to the marine environment.

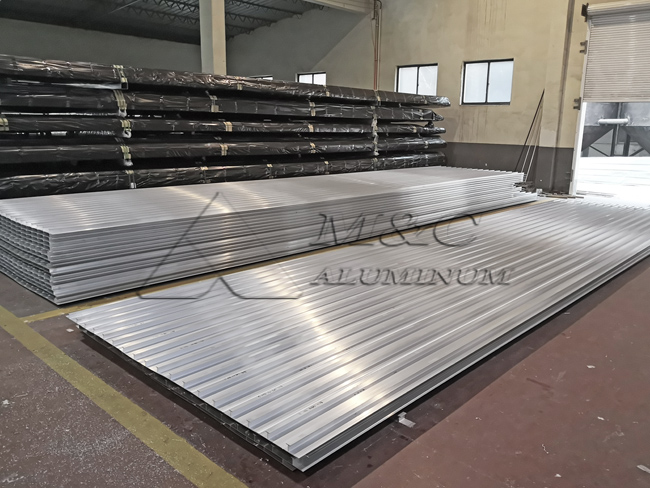

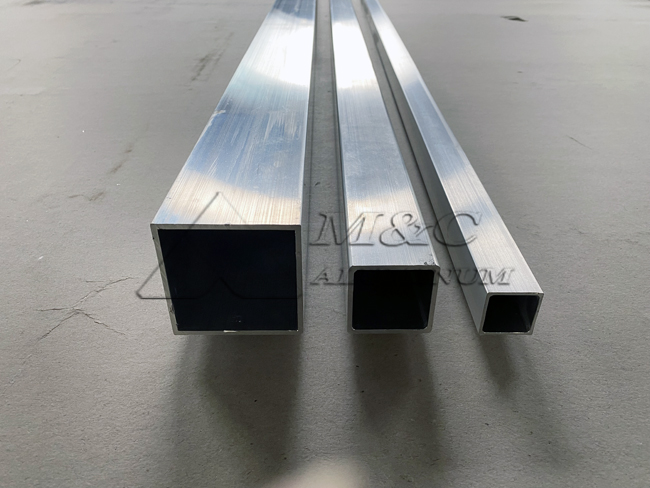

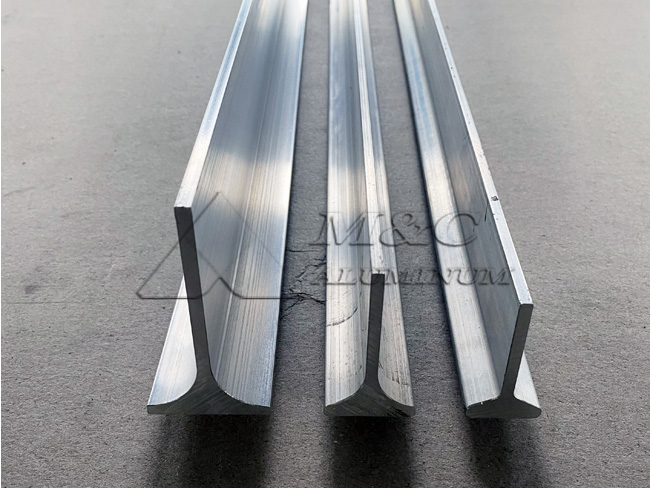

Common marine structural profiles include angular aluminum, T-type aluminum, aluminum trough, aluminum tubes, bars, plates, etc. The marine aluminum alloys available are 5083, 5052, 5383, 6061, 6063, 6082, etc. Customers can provide specific specifications or suggestions, and MC Aluminum can provide customized solutions according to specific needs.

Common types and applications of marine aluminum profiles:

Hull structure aluminum profile:

Alloy type: 5083, 5086, 5456, 6061, 6082, etc.

Application scenarios: used for structural components such as hull frames, keels, bulwarks, etc., which can effectively reduce the weight of the hull and improve speed and fuel efficiency.

Advantages: excellent corrosion resistance, high strength, easy processing and welding.

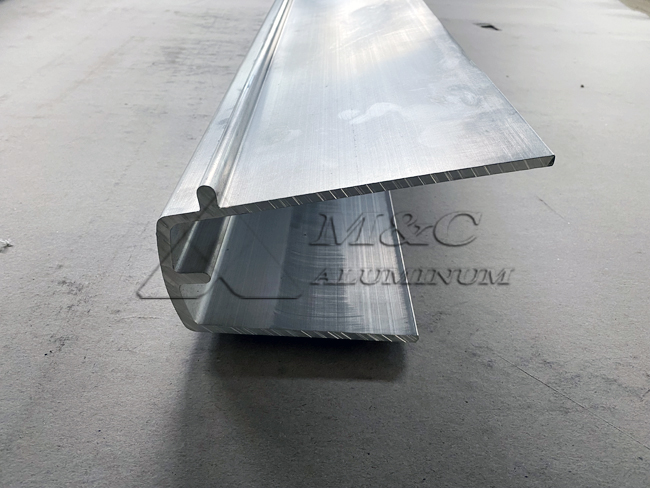

Deck and cabin aluminum profiles:

Alloy types: 6061, 6082, etc.

Application scenarios: used to make ship decks, cabin partitions and other ship interior decoration and functional parts, such as handrails, stairs, etc.

Advantages: light, can reduce the overall hull load, and has a high surface finish, resistant to seawater and chemical corrosion.

Ship-specific extruded aluminum profiles:

Alloy types: 6000 series, 5000 series aluminum alloys.

Application scenarios: Extruded aluminum profiles are used for various frame structures, stiffeners and profile components, etc.

Advantages: strong customization, can be extruded according to different shapes and sizes to ensure that it adapts to the complex structural design of ships.

Advantages of MC Aluminum Marine Aluminum Profiles

1. Good corrosion resistance: treated aluminum alloys can effectively resist salt water and moisture corrosion in the marine environment.

2. Lightweight: aluminum has a lower density than steel, which helps to reduce the weight of the ship, increase speed and reduce fuel consumption.

3. High strength: Modern aluminum alloys have sufficient mechanical strength after reasonable heat treatment to meet the needs of ships.

4. Machinability and customization: Aluminum profiles can be customized by extrusion, welding, cutting and other methods to meet the needs of different ship types and functions.

5. Excellent welding performance: The performance of aluminum joints is stable after welding, and it is not easy to produce defects such as cracks after welding, which is conducive to the stability and sealing of ship structures.

Aluminum profile customization process

1. Demand determination: Determine the required aluminum profile specifications, shapes, and alloy types according to the ship design plan and use environment.

2. Select materials: such as 5052, 5083, 6061, 6082, according to strength, corrosion resistance, and machinability.

3. Design drawing: Draw detailed drawings, including cross-sectional shape, size, connection method, and review.

4. Mold making: Make extrusion molds according to drawings to ensure accuracy and durability.

5. Manufacturing and processing: Aluminum is processed by extrusion, rolling and other processes, and welding, surface treatment (such as anodizing) and other processes can also be performed if necessary. Control the temperature and speed during the production process to ensure the size and surface quality.

6. Subsequent processing: cutting, punching, tapping and other processing, and surface treatment (such as anodizing).

7. Quality inspection: Check the dimensional accuracy, surface quality and performance to ensure that it meets the design requirements and passes the ship industry certification standards (ISO, DNV, ABS, etc.).

How much does it cost to customize aluminum profiles per ton?

The cost of customized aluminum profiles is generally the base price of aluminum ingots + processing fees (material extrusion, surface treatment) + mold fees. The mold fees are generally refundable, provided that the order volume reaches a certain amount.

The price of customized marine aluminum profiles is affected by many factors, including aluminum alloy grades, specifications, quantities, design requirements, production processes, etc. Therefore, before customization, it is necessary to communicate with the supplier in detail to clarify the price composition and calculation method in order to make a reasonable budget and procurement plan.

MC Aluminum is a professional manufacturer of marine aluminum alloys, including aluminum plates, patterned aluminum plates, ribbed plates, aluminum profiles, etc. It provides classification society certification and can be customized according to customer needs. It has a complete range of product models and excellent quality. It is exported to many countries and regions overseas and is very popular with customers.