Marine aluminum alloy sheet refers to thin aluminum alloy sheet used in the field of shipbuilding. On ships, these sheets are mainly used for ship superstructures (such as cabs, crew living cabins, etc.), interior decoration, ventilation systems, and some hull structures (such as the outer shell of some small ships).

Due to its own alloy properties and advantages after cold rolling, 5052 cold-rolled aluminum sheet meets the requirements of corrosion resistance, high strength, good weldability and excellent processability, so it has become the preferred material for marine aluminum alloy sheet.

5052 cold-rolled aluminum sheet is a high-performance aluminum sheet made by cold rolling process based on aluminum-magnesium alloy (5 series). Due to its excellent corrosion resistance, moderate strength, good processability and lightweight characteristics, it has become a widely used material in shipbuilding.

Specifications of 5052 marine grade aluminum for shipbuilding

| Alloy | 5052 |

| Temper | O, H32, H26, H36, H22, H28, H38, H111, etc |

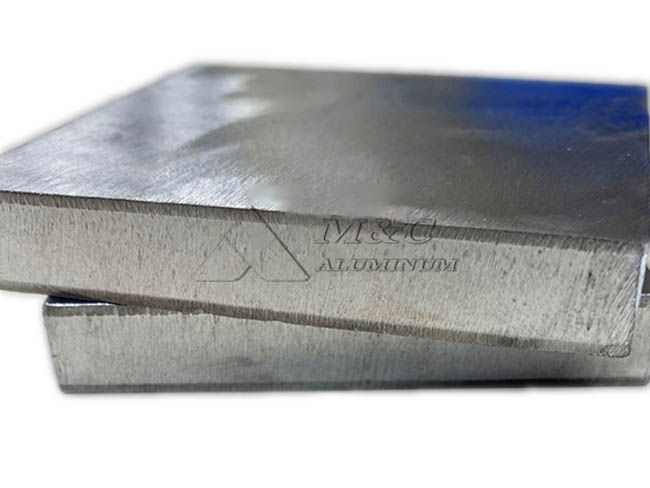

| Thickness | 3-50mm |

| Width | 100-2650mm |

| Length | 1000-16000mm |

| Certification | CCS, DNV, NK, ABS, BV, LR and other classification society certificates |

| Packaging | Standard export packaging, such as wooden box or as required. |

| MOQ | 1-3 tons |

Chemical composition of 5052 marine grade aluminum plate

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | remainder |

Mechanical properties of 5052 marine aluminum plate

Temper | Thickness (mm) | Tensile Strength MPa | Yield Strength MPa | Elongation % | Hardness HB |

O, H111 | 3-50 | Min. 165 Max. 215 | Min. 65 | 12 - 19 | 47 |

H22, H32 | Min. 210 Max. 260 | Min. 130 | 5-12 | 61 | |

H24, H34 | Min. 230 Max. 280 | Min. 150 | 4-9 | 67 | |

H26, H36 | Min. 250 Max. 300 | Min. 180 | 3-6 | 74 | |

H28, H38 | Min. 270 | Min. 210 | -3 - 4 | -3 - 4 |

Why choose 5052 instead of other materials?

1. Anti-corrosion in marine environment: Contains 2.2%-2.8% magnesium, which can effectively resist corrosion in seawater, salt spray and humid environment.

2. High strength and light weight: With moderate tensile strength and good toughness, it can meet the structural requirements of ships, while reducing the weight of the hull and improving fuel efficiency.

3. Excellent processing performance: The cold rolling process ensures that the surface of the plate is flat, easy to weld, cut and bend, and suitable for the manufacture of complex hull structures.

4. Low temperature adaptability: Maintains good performance in cold environments, suitable for ships sailing in polar or low-temperature waters.

5. Good weldability: 5052 aluminum alloy has good weldability, ensuring the structural strength and sealing during the hull manufacturing process.