Yes, 5052-H32 aluminum is considered a type of marine-grade aluminum alloy.

“Marine-grade aluminum alloy” typically refers to alloys that offer excellent corrosion resistance in marine environments (especially seawater corrosion) and good mechanical properties. The 5000 series marine aluminum alloys, thanks to their primary alloying element—magnesium—perform exceptionally well in these areas.

What is 5052-H32 Aluminum Plate?

5052 Alloy Composition Features: Belongs to the Aluminum-Magnesium (Al-Mg) series, with magnesium content around 2.2–2.8%. It has excellent corrosion resistance, especially in atmospheric and seawater environments.

H32 Temper Definition: A half-hard temper achieved through moderate strain hardening followed by stabilizing anneal. H32 is widely used within the 5052 series, balancing strength with formability.

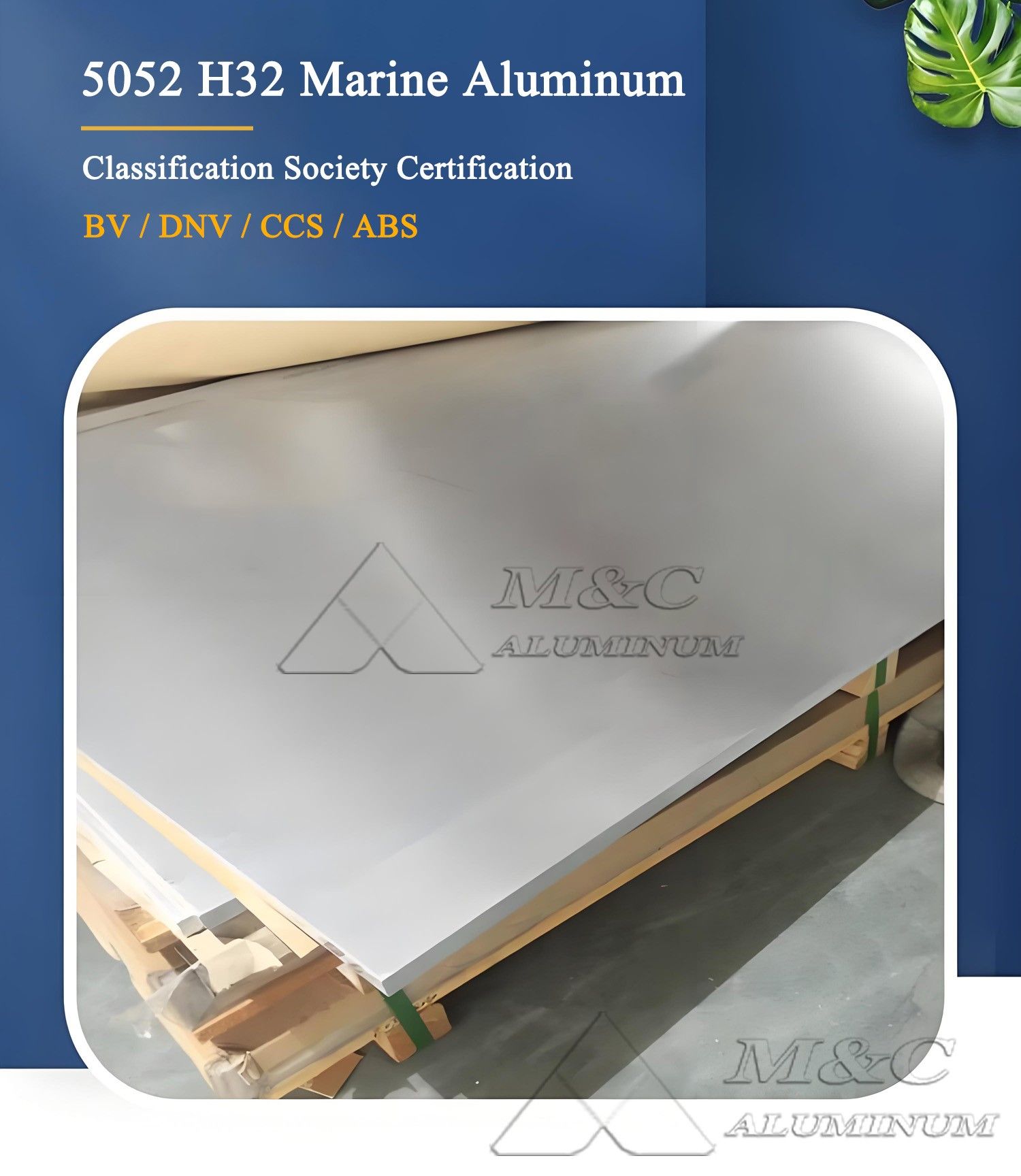

5052-H32 Marine Aluminum Plate Product Introduction

| Alloy | 5052 |

| Temper | H32 |

| Thickness | 3-50 mm |

| Width | 1000-2650 mm |

| Length | 1000-16000 mm |

| Surface Finish | Anodized, mill finish, matte, brushed, oxide film |

| Certification | BV, DNV, CCS, ABS and other classification societies |

| Packaging | Standard marine packaging, customizable |

| Delivery Time | 25-35 days |

| MOQ | 1-3 tons |

Mechanical Properties

| Property | Typical Value |

| Tensile Strength (σb) | 210 - 260 MPa |

| 0.2% Proof Stress (σ0.2) | 130 - 195 MPa |

| Elongation (A50) | 7% - 12% |

| Brinell Hardness (HB) | ≈ 60 - 65 |

| Elastic Modulus | ≈ 70 GPa |

| Density | ≈ 2.68 g/cm³ |

| Thermal Conductivity | ≈ 138 W/(m·K) |

| Electrical Conductivity (%IACS) | 33 - 35 |

Marine Characteristics of 5052-H32

Corrosion Resistance: Excellent resistance to seawater and marine atmosphere. Magnesium addition improves oxidation and pitting resistance.

Strength-to-Weight Ratio: Medium strength and lighter than steel, helping reduce overall vessel weight and improve fuel efficiency.

Formability: Outstanding cold working properties, easy to bend, stamp, and deep draw—ideal for manufacturing complex marine shapes.

Weldability: Excellent weldability, compatible with common methods like MIG and TIG, critical for structural assembly in shipbuilding.

Common Marine Applications of 5052-H32

Small boat and yacht hulls: Especially in freshwater environments or saltwater where extreme strength is not critical.

Decks, cabin tops, and other non-structural components: Great for parts requiring bending or complex shapes due to excellent formability.

Other internal ship components and equipment.

Comparison with Other Marine-Grade Aluminum Alloys

While 5052-H32 is an important marine-grade aluminum alloy, it’s important to note that there are other alloys designed for even higher performance in certain marine applications:

5083 and 5086 Aluminum Alloys: Higher magnesium content, typically regarded as higher-tier marine-grade alloys with greater strength and superior seawater corrosion resistance (including better resistance to stress corrosion cracking and exfoliation). Commonly used for large vessel structures, high-stress hull sections, and ships operating in harsher marine environments.

6061 Aluminum Alloy: Belongs to the Al-Mg-Si series, heat-treatable. Offers good corrosion resistance, strength, and weldability. Commonly used in structural frameworks, masts, and tubing on vessels.

In Summary

5052-H32 marine aluminum plate is widely recognized as a marine-grade aluminum alloy, particularly well-suited for applications requiring excellent formability, moderate strength, and superior corrosion resistance (including seawater environments).