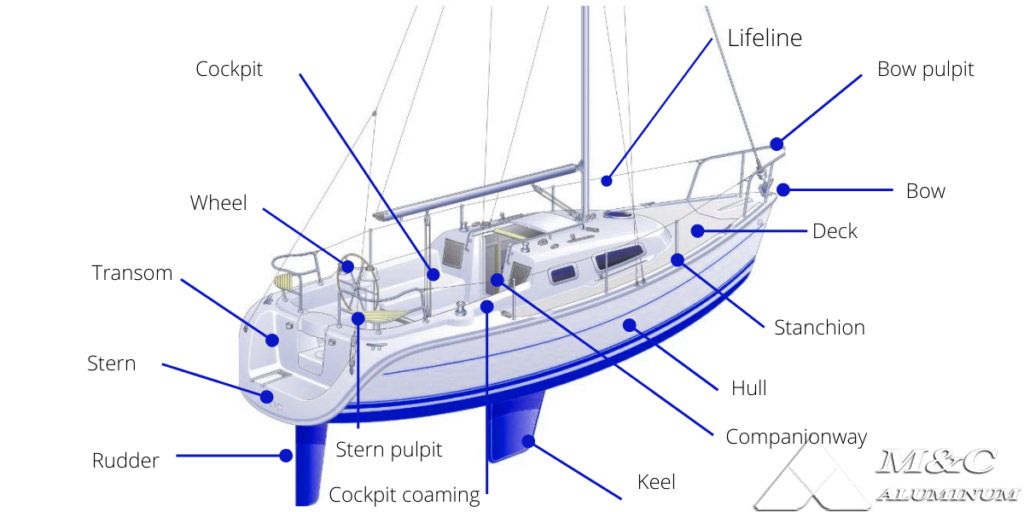

Introduction to ship keel

The keel is a longitudinal member connecting the bow column and the stern column in the center of the base of the hull. It is located at the bottom of the ship and is usually the first part of the ship to be built. The main function of the keel is to bear the longitudinal bending moment of the hull. The second function is to expand the side area of the ship, increase the parallel impedance of the ship in the water, and prevent the side wind from turning, which is especially important for sailing against the wind. In addition, the keel also plays an important role in the weight stability of the ship, reducing the tilt or reverse rotation of the ship.

Introduction to ship aluminum alloy

5083 aluminum sheet is an Al-Mg alloy with magnesium as the main alloying element. It is a typical rust-proof aluminum sheet. It has good corrosion resistance and medium strength. It is particularly suitable for use in marine environments, such as the keel of ships and other key parts. In addition, 5083 aluminum sheet also has good weldability and cold processing properties, which is convenient for various processing and welding operations during ship manufacturing.

Therefore, choosing 5083-H116 and 5083-H321 aluminum sheets as the material for the ship's keel can ensure the strength and durability of the ship, and is also conducive to improving the manufacturing efficiency and quality of the ship. In the shipbuilding industry, marine-grade 5083 aluminum sheets have been widely used and a stable production process has been formed.

5083 aluminum plate specification requirements

| Alloy | 5083 |

| Temper | H116, H321, etc |

| Thickness | 3-50mm |

| Width | 1000-2650mm |

| Length | 1000-16000mm |

5083 mechanical properties

| Tensile strength | ≥275 MPa |

| Yield strength | ≥125 MPa |

| Elongation | ≥20% |

Chemical composition of 5083 marine aluminum plate

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

5083 marine aluminum sheet application areas

1. Ship keel and bottom plate structure

2. Ship bulkhead, deck, hull and other parts

3. Other hull structural parts that require high corrosion resistance and high strength

Keel performance requirements for aluminum plate

1. Light weight: low aluminum density (2.71g/cm³), reducing the weight of the ship, improving performance and economy.

2. High strength: high tensile strength and yield strength are required to withstand large loads.

3. Corrosion resistance: can resist seawater erosion well and is suitable for long-term use in marine environment.

4. Easy to process and weld: good processing performance and welding performance make the manufacturing process smoother.

5. Good surface condition: the surface is smooth, flat, and undamaged, and the appearance is beautiful after anodizing.

6. Recyclable: highly recyclable, in line with sustainable development requirements, and reduce environmental impact.

Marine aluminum plate quality inspection standards for keels

1. Surface quality: the surface is flat, without cracks, oxidation spots, scratches and other defects.

2. Ultrasonic flaw detection: no internal pores, inclusions and other defects (in accordance with ASTM B594 standard).

3. Corrosion resistance test: in accordance with GB/T 228.1 or ISO 6892 standard requirements.

4. Classification society certification: must pass relevant classification society certification (such as CCS, ABS, DNV, LR) to ensure that the material meets the international specifications for shipbuilding.