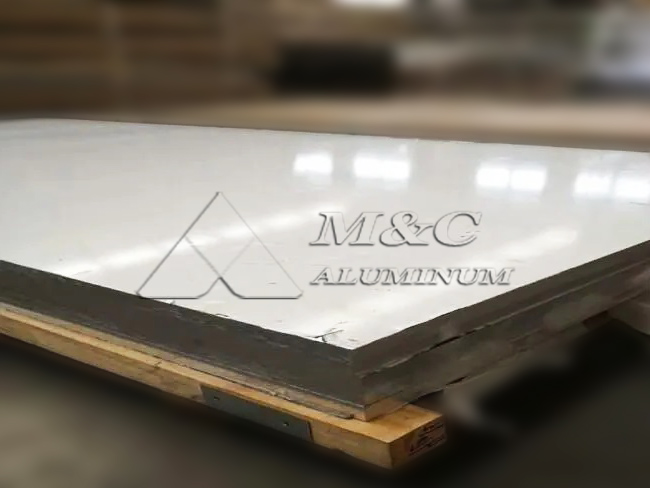

5083 aluminum alloy plates, as a typical 5xxx series Al-Mg alloy, are widely used in shipbuilding and marine engineering due to their excellent resistance to seawater corrosion and weldability. Marine-grade 5083 aluminum is particularly suitable for applications exposed to harsh environments, including seawater, chemicals, and extreme weather conditions.

Temper States: H321 and H116

Both H321 and H116 tempers are specifically designed for marine applications of 5083 aluminum plates, providing high resistance to stress corrosion cracking (SCC).

H116 Temper:

Designed for marine products with high sensitivity to stress corrosion, such as hull panels. Controlled rolling and heat treatment processes ensure maximum resistance to exfoliation and stress corrosion.

H321 Temper:

A strain-hardened and stabilized temper with slightly higher strength than H116, while still offering excellent corrosion resistance. Ideal for structural components requiring both high strength and weldability.

Standard Dimensions and Specifications

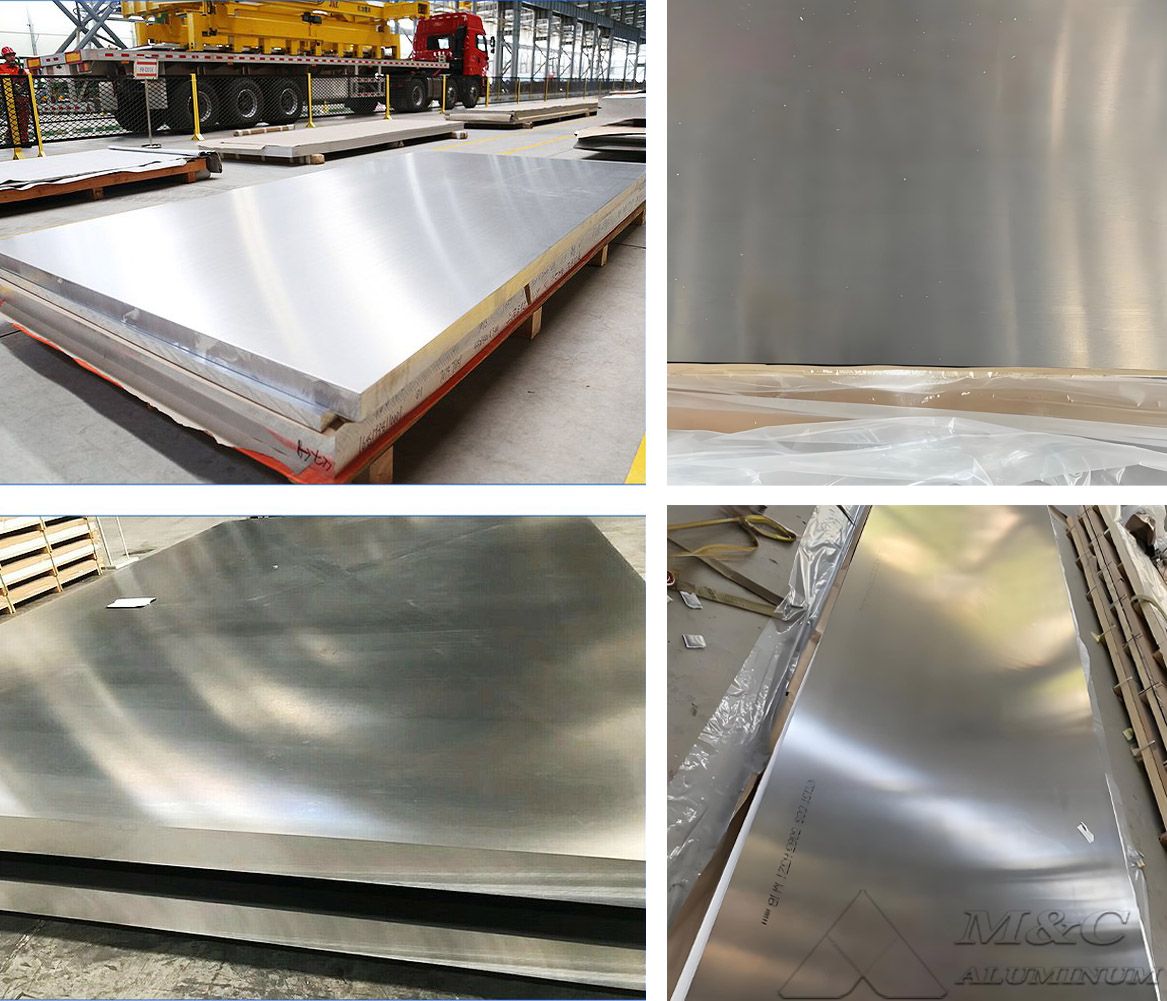

MC Aluminum produces plates sized 1200mm x 2400mm (1.2m x 2.4m), which are easy to transport, store, and cut on-site, maximizing material utilization.

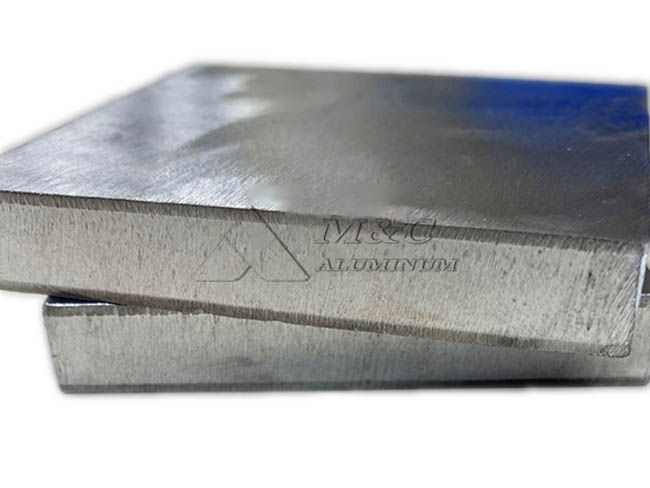

Specifications of 5083 marine aluminum plate

| Material Grade | 5083-H321 / H116 |

| Dimensions | 1200mm x 2400mm |

| Thickness | 3.0mm |

| Weight | 23.4 kg |

| Surface | Smooth mill finish, ready for use or further processing |

| Application | Designed for heavy-duty projects requiring corrosion resistance and strength |

| Sample | Available |

| Packaging | Standard maritime packaging |

| MOQ | 1-3 tons |

Performance Advantages of 5083-H321/H116 Aluminum Plates

1. Lightweight: Aluminum weighs only 1/3 of steel, reducing overall hull weight, improving speed, and fuel efficiency.

2. Seawater Corrosion Resistance: Long-term use in saltwater and high-humidity environments without rusting or flaking.

3. Excellent Weldability: Suitable for various welding methods (TIG, MIG, etc.) with high weld strength.

4. Strength and Toughness: Withstands wave impact and structural stress, with superior fatigue resistance.

5. Flexible Processing: Can be bent, punched, and cut, adapting to diverse design and construction needs.

Typical Marine Engineering Applications

Shipbuilding

Hull panels for workboats, patrol boats, and fishing vessels

Superstructures for large vessels, lowering the ship’s center of gravity

Bulkheads and deck panels

Offshore Oil Platforms

Helicopter deck panels

Walls and roofs of living modules

Walkways, anti-slip flooring, and stair treads

Maritime Equipment and Structures

Desalination plant tanks and pipelines

Dockside auxiliary facilities

Seafood transport containers

Classification Society Certifications: 5083 Marine Aluminum Plates

MC Aluminum's 5083 marine-grade aluminum plates are certified by DNV-GL, ABS, CCS, and other classification societies, ensuring the quality and safety of materials used in marine engineering projects.

Original Source: https://www.marinealum.com/a/1200mm-x-2400mm-x-30mm-5083-h321-h116-aluminum-plate-for-marine-engineering-projects.html

Tag: 5083 marine aluminum plate 5083 marine-grade alloy 5083 H321 marine aluminum plate 5083-H321 aluminum plate 5083-H116 aluminum plate 1200x2400mm aluminum plate marine engineering aluminum plate 5083 aluminum plate manufacturer DNV-certified alumin