As early as August 1931, the UK built the Diana, the world's first all-aluminum yacht, pioneering aluminum shipbuilding.

With the development of the marine economy, shipbuilding companies have been continuously seeking lighter, more durable, and easier-to-process materials to reduce fuel consumption, increase sailing speed, and extend service life.

6061 aluminum plate, a heat-treatable aluminum alloy with magnesium and silicon as the main alloying elements, combines high strength + weldability + machinability, making it an ideal choice to meet the requirements of Zhoushan's high-salt marine environment, lightweight ship design, and heavy-duty port equipment.

In marine salt spray tests, 6061 aluminum plate showed no significant corrosion for 1200-1800 hours, which is 8-10 times longer than ordinary carbon steel, effectively resisting the erosion of high-salt, high-humidity coastal environments.

In fishing vessel manufacturing, 6061 marine aluminum sheets are mainly used for structural frameworks, decks, bulkheads, as well as various ship accessories and hardware.

Tempers

T6: Solution heat-treated and artificially aged.

T451: Solution heat-treated, stress-relieved, then naturally aged.

T651: Solution heat-treated, stress-relieved by stretching, then naturally aged.

T6511: Solution heat-treated, stress-relieved by stretching, artificially aged, and slightly straightened.

Professional Classification Society Certification

6061-T6 marine aluminum sheets used in shipbuilding must pass certification by CCS (China Classification Society) or DNV GL, ensuring excellent seawater corrosion resistance.

MC Aluminum’s 5000 and 6000 series marine aluminum plates have already obtained certifications from CCS and DNV.

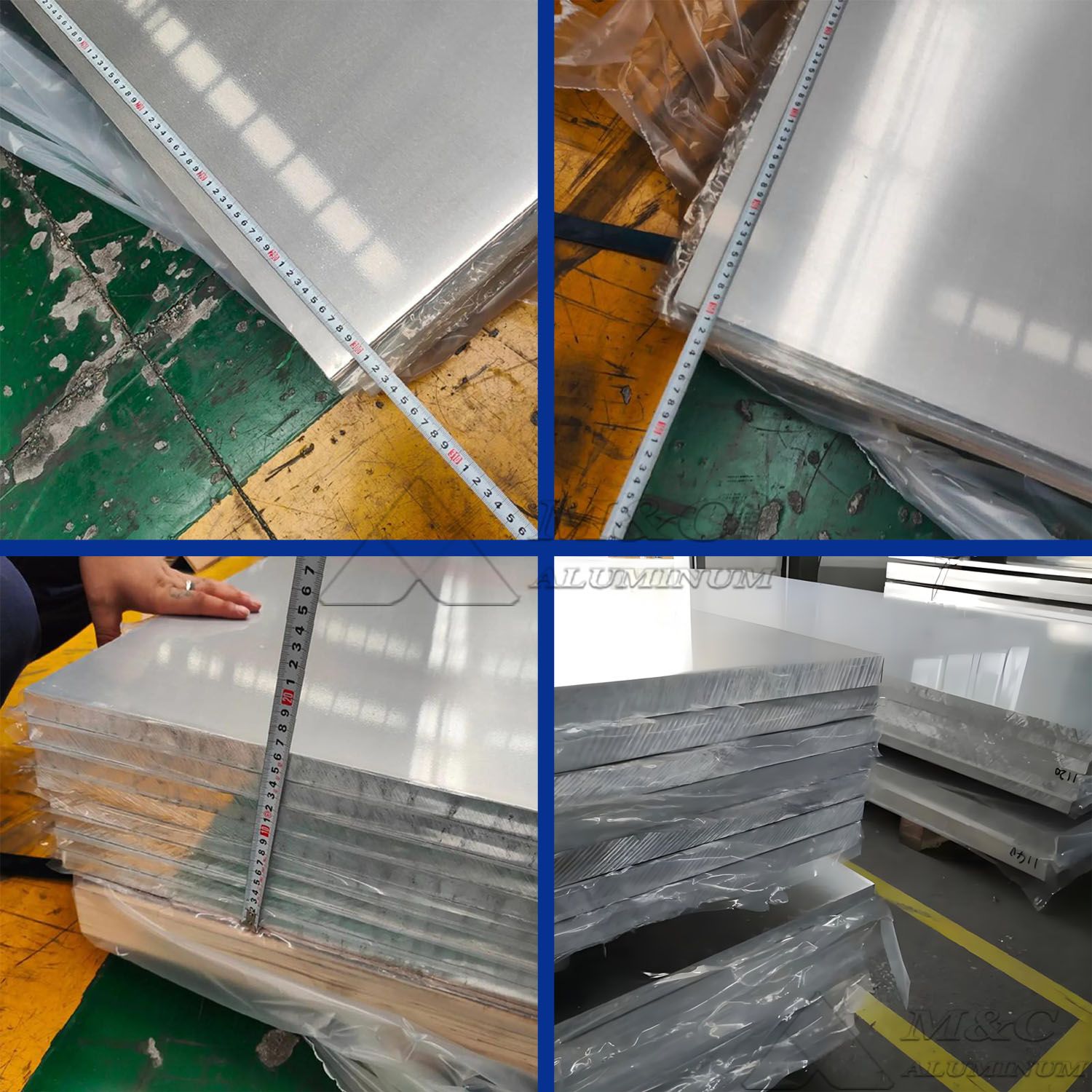

Marine Aluminum Plate Specifications

Alloy: 6061

Tempers: O, T6, T451, T651, T6511

Thickness: 3-50 mm

Width: 1000-2650 mm

Length: 1000-16000 mm

Mechanical Properties of 6061-T6 Aluminum Sheet

Tensile strength: 310-380 MPa

Yield strength: 275-310 MPa

Advantages of 6061 Marine Aluminum Sheet

1. Lightweight: Aluminum density is only one-third that of steel. Using 6061 marine aluminum sheets in fishing vessels significantly reduces hull weight, increasing vessel speed, reducing fuel consumption, and improving operational efficiency.

2. Corrosion resistance: Fishing boats operate long-term in high-salinity seawater. Traditional steel ships are prone to rust and corrosion, while 6061 aluminum sheets, after anodizing or protective coating, resist seawater corrosion effectively, extending service life by 5-10 years compared to steel ships.

3. Weldability: 6061 aluminum sheets have excellent welding performance, with no tendency toward stress-corrosion cracking. They feature good weldability and cold workability.

4. Machinability: 6061 sheets in O and T4 tempers are suitable for bending and forming, while T5 and T6 tempers are ideal for applications requiring good machinability.

5. High strength & safety: 6061 aluminum offers higher strength than common 5 series marine aluminum (such as 5083, 5052), capable of withstanding strong wave impacts, ensuring hull stability, and improving navigation safety.

6. Eco-friendly & recyclable: Aluminum alloys are recyclable, supporting sustainability in the fishing and shipbuilding industries.

Applications of 6061 Marine Aluminum Sheet

6061 aluminum sheet has become a core material for ship structures and accessories. In the shipbuilding sector, 5-15mm thick 6061-T6 aluminum sheet is commonly used to manufacture decks, side panels, bulkheads, and other components for small vessels.

In the shipbuilding accessories sector, 6061 aluminum sheet is widely used in engine cooling components, pipe supports, and guardrail structures.

The application of 6061 aluminum sheet in marine engineering is growing. In the offshore wind power sector, 8-20mm thick 6061-T6 aluminum sheet is commonly used to manufacture platform treads, equipment supports, and cable trays for wind turbine towers.

Surface Treatment & Processes

To enhance the service life and appearance of 6061 marine aluminum sheets, the following treatments are commonly used:

Anodizing: Improves corrosion resistance and forms a protective oxide layer.

Patterned anti-slip sheets: Used for decks and work platforms to prevent slipping.

Spraying/coating: Enhances weather resistance and decorative effects.

Heat treatment: T6 temper significantly improves strength.

Dimensions

MC Aluminum produces 6061 aluminum plates in thicknesses ranging from 3-50 mm and widths from 600-2650 mm, meeting various shipbuilding requirements.

Common sizes: 2x6m, 2x8m, with custom options available.

MC Aluminum manufactures marine-grade 6061 sheets with thicknesses from 3.0-50 mm, widths of 1000-1600 mm, and in multiple tempers including T4, T6, and T651. All products are certified under ISO 9001 quality management and approved by major classification societies (CCS, LR), fully meeting marine industry standards.

Original Source: https://www.marinealum.com/a/6061-aluminum-sheet-for-fishing-vessels.html

Tag: 6061 marine aluminum sheet 6061 marine-grade aluminum plate 6061-T6 marine aluminum sheet 6061 shipbuilding aluminum 6061 aluminum plate for boats 6 series marine aluminum plate 5 series marine aluminum plate 2x6m marine aluminum plate 2x8m marine