With the growing trend toward lightweight and energy-efficient ships, aluminum plates have increasingly replaced traditional steel materials in marine construction.

Among these, 5052 aluminum plate has become an important material for marine sheet metal components due to its excellent corrosion resistance, superior weldability, and high strength-to-weight ratio.

What Are Marine Sheet Metal Components?

Marine sheet metal components are structural and functional parts used in ships, yachts, offshore structures, and naval vessels. Common types include:

Hull Plates

Hull plates form the exterior of a ship and must withstand water pressure and wave impacts.

They require high strength and rigidity.

Typically, hull plates are made from high-strength 5083 or 5052 aluminum plates to ensure stability even in harsh sea conditions.

Decks

Decks provide platforms for crew and equipment. They must bear weight from equipment and cargo while offering sufficient friction to prevent slipping.

Decks are often made from materials with anti-slip surfaces to ensure safety.

Bulkhead Plates

Bulkheads divide internal spaces of a ship, providing structural support, fire protection, and sound insulation.

Material selection and thickness are carefully designed to meet specific functional and safety requirements.

What Is 5052 Marine Aluminum Plate?

5052 marine aluminum plate is an aluminum-magnesium alloy with a tensile strength of 18-51 ksi (non-heat-treatable).

Among non-heat-treatable alloys, 5052 has relatively high strength.

It is easy to weld and particularly suitable for marine environments.

Temper Conditions:

O (Annealed): Best ductility, ideal for deep drawing and forming.

H32: Balanced strength and formability, commonly used in marine sheet metal components.

H34: Higher strength, suitable for load-bearing parts.

5052 Marine-Grade Aluminum Plate Specifications

| Temper | O, H32, H34, H112 |

| Thickness | 3mm - 50mm |

| Width | 1000mm - 2000mm |

| Length | 2000mm - 6000mm |

| Tensile Strength | 210 - 260 MPa (H32) |

| Yield Strength | ≥130 MPa |

| Elongation | ≥12% |

| Hardness (Brinell) | 60 - 70 HB |

| Density | 2.68 g/cm³ |

| Thermal Conductivity | 138 W/m·K |

| MOQ | 1-3 tons |

Why Choose 5052 Aluminum Plate for Marine Sheet Metal?

1. Excellent Seawater Corrosion Resistance:

Forms a strong oxide layer, keeping surfaces smooth and protected during long-term marine exposure.

2. Ductility Combined with Strength:

Provides sufficient structural support while allowing complex shapes and forming.

3. Lightweight for Energy Efficiency:

Reduces overall hull weight, improving fuel economy.

4. Easy to Weld and Repair:

Simplifies maintenance and replacement of ship components.

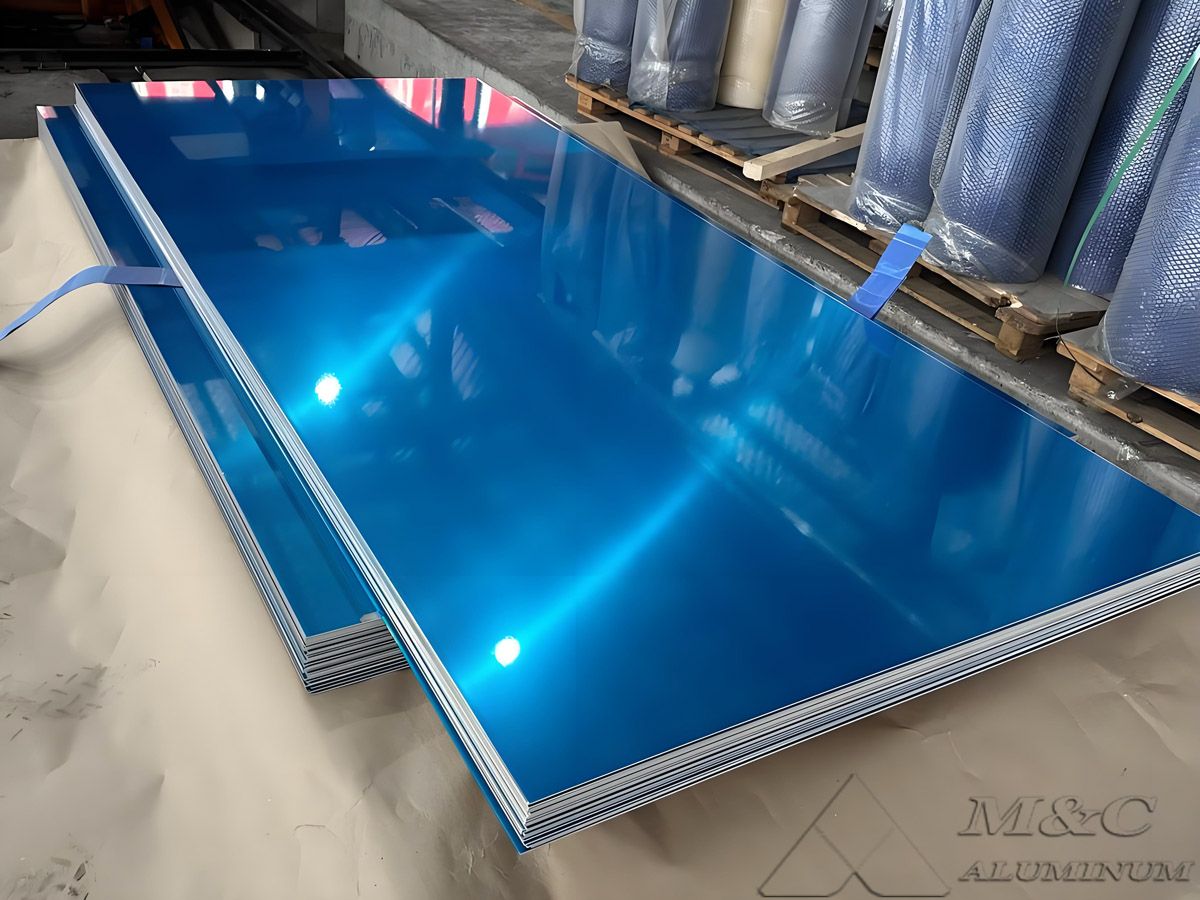

5. Aesthetic and Decorative Surface:

Can be anodized to silver or colored finishes, offering both functional and decorative benefits.

6. Low Maintenance and Long Service Life:

Natural corrosion resistance extends lifespan and reduces maintenance costs and downtime.

Applications of 5052 Aluminum Plate in Shipbuilding

Superstructures:

Cabin walls, bridge structures, and top decks for lightweight design.Deck Components:

Hatch covers, platforms, ladders, railings, etc.Ship Accessories:

Storage cabinets, fuel tanks, water tanks, ventilation ducts.Yachts and Speedboats:

Widely used for hulls and interior components due to corrosion resistance and aesthetic appeal.

Processing and Manufacturing of 5052 Marine Aluminum Plates

1. Cutting and Shaping:

Plates can be processed by laser cutting, CNC punching, or shearing, ensuring high precision and smooth edges.

2. Bending and Welding:

Excellent bendability makes 5052 ideal for sheet metal bending.

Welding methods include TIG, MIG, and laser welding, providing strong joints with high structural integrity.

3. Surface Treatment:

Options include anodizing, electrophoretic coating, fluorocarbon spraying, or anti-slip patterns to improve aesthetics and corrosion resistance.

4. Inspection and Assembly:

Components undergo dimensional checks, stress tests, and corrosion protection inspection before assembly to ensure safety and long-term stability.