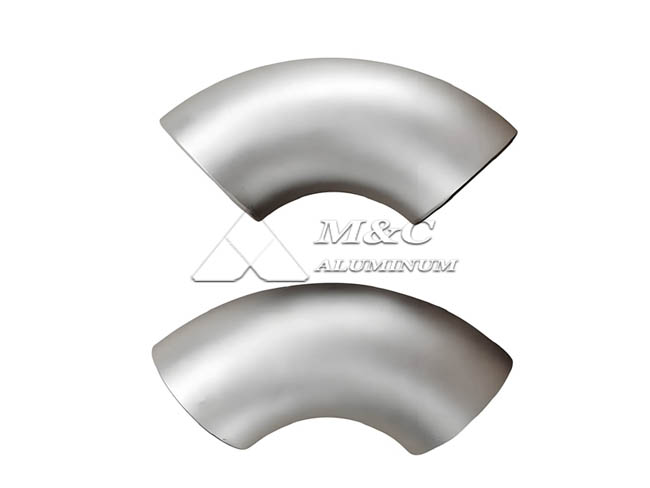

The aluminum alloy 90-degree elbow is a common pipe fitting used to change the direction of fluid flow by 90 degrees. Due to the excellent properties of aluminum alloys, these elbows are widely applied in various industrial and civil pipeline systems.

Common Aluminum Alloy Grades:

6061-T6: High strength, good corrosion resistance, easy to weld. Ideal for structural and general engineering applications.

5083-H112: Excellent resistance to seawater corrosion, suitable for marine and chemical environments.

7075-T651: Ultra-high strength for demanding applications such as aerospace and military.

3003, 1060 series: Lightweight and cost-effective, suitable for low-pressure systems.

Size Range:

| Specification | Range / Options |

| Nominal Diameter (DN) | DN10 (10 mm) to DN100 (100 mm) or larger (e.g., DN150, DN200) |

| Centerline Radius (R) | 1D, 1.5D, 2D, 3D (D = nominal diameter) |

| Wall Thickness (t) | Typically 1 mm to 5 mm depending on pressure rating and alloy |

| Elbow Angle | 45°, 90°, 180°, etc. |

| Length (L) | Generally 50 mm to 300 mm, customizable based on project needs |

Advantages of 90-Degree Aluminum Elbows

Compared to carbon steel or stainless steel elbows, aluminum alloy elbows offer unique benefits such as lightweight, corrosion resistance, and ease of processing—making them increasingly popular among engineers.

1. Lightweight Design

Aluminum has a density of approximately 2.7 g/cm³—about one-third that of steel. This significantly reduces the overall weight of equipment, which is crucial for aerospace, rail transportation, and other weight-sensitive applications.

2. Excellent Corrosion Resistance

A naturally formed oxide layer protects aluminum from water, oils, and mild corrosive media. This makes aluminum elbows especially suitable for petrochemical, marine, and food-grade systems.

3. Superior Machinability & Weldability

Aluminum alloys have excellent ductility and can be formed using extrusion, forging, CNC machining, etc. They are compatible with various connection types—welding, clamps, threads, quick-connects, and more.

4. Good Thermal Conductivity

Ideal for hot fluid or cooling systems, aluminum offers efficient thermal conduction, enhancing the performance of temperature control systems.

5. Eco-Friendly & Recyclable

Aluminum alloy elbows are highly recyclable and align with sustainable development goals and green manufacturing initiatives.

Application Areas:

HVAC Systems: Aluminum elbows reduce the weight and installation complexity of ventilation and air conditioning pipelines.

Industrial Piping: Compatible with chemical and energy industries, offering high-pressure resistance and excellent sealing.

Architecture & Construction: Suitable for aesthetic or weight-sensitive applications like railings, structural frames, etc.

Aerospace: High-strength aluminum elbows are used in ultra-lightweight, performance-critical systems.

Machinery: Connective components in various mechanical equipment and devices.

Automotive Industry: Used in exhaust systems, intake pipes, cooling systems—leveraging their lightweight and thermal properties.

Manufacturing Processes:

1. Extrusion Forming

Aluminum billets are pushed through a die using an extruder to form elbows. Ideal for high-volume production with good dimensional accuracy and surface finish.

2. Forging

Aluminum is shaped under high pressure using molds, resulting in dense material structure and enhanced strength—suitable for high-pressure or high-temperature pipelines.

3. Welded Assembly

Multiple aluminum segments are welded and polished into an elbow shape—used for large-diameter or custom-designed elbows.

4. CNC Machining

Precision processing for small-diameter elbows or unique geometric designs using CNC equipment.

How to Select the Right Aluminum Alloy 90-Degree Elbow:

Pressure Rating: Determine the operating pressure of the system and select the elbow thickness and alloy accordingly.

Connection Type: Choose from welding (butt/socket), threaded, compression, or quick-connect based on pipe design.

Dimensions: Standard nominal diameters range from DN10 to DN600, with wall thickness as per standard or custom requirements.

Corrosion Resistance: For marine or harsh environments, 5083 or 6063 alloys are recommended.

Heat Treatment Condition: T6 (solution heat-treated + artificially aged) enhances mechanical performance.

Certifications: Ensure compliance with ISO, ASME, or other project-specific standards.