According to the latest data from the International Shipbuilding & Offshore Materials Research Association, the global marine aluminum alloy plate market is projected to grow at an average annual rate of over 6.5% from 2024 to 2028. Among this, 5000 series aluminum-magnesium alloys and 6000 series aluminum-magnesium-silicon alloy plates are expected to account for more than 85% of total demand.

MC Aluminum has proactively invested in the marine aluminum plate sector, with an annual production capacity of 200,000 tons of marine-grade aluminum alloy plates. Our products have obtained certifications from multiple international classification societies (CCS, DNV, LR, ABS, etc.), fully meeting shipbuilding standards and requirements.

5000 Series Marine Aluminum Alloys

The 5000 series alloys are magnesium-based and renowned for their excellent corrosion resistance (especially in marine environments) and good weldability. These are non-heat-treatable alloys whose strength is primarily achieved through cold working (strain hardening).

Typical Marine Applications and Grades

5000 series alloys are widely used in hulls, decks, rivets, propellers, ship structures, tanks, pipelines, pressure vessels, and offshore platforms.

5052: The most common grade, suitable for freshwater vessels, offering good formability and excellent corrosion resistance. Often used for hulls, bottoms, bulkheads, and partitions.

5083: Considered the “gold standard” for marine use, with outstanding strength and corrosion resistance in seawater. Ideal for hulls, offshore platforms, and LNG storage tanks. Available in H111, H112, H116, and H321 tempers.

5086: Slightly lower strength than 5083 but with even better corrosion resistance. Used in electrical systems, piping, and other ship components. Easier to form than 5083.

5754: Resistant to seawater and chloride corrosion, suitable for offshore structures and oilfield equipment. Medium strength and easy to process.

5383: An improved version of 5083, offering higher strength and better weldability.

Advantages of 5000 Series Marine Aluminum Plates

Corrosion resistance: Forms a dense oxide layer, highly suitable for high salt-spray environments, with service life exceeding that of steel by over 30%.

Weldability: Excellent for MIG/TIG welding, with weld strength reaching ~90% of base metal, and minimal heat-affected zone degradation.

Low-temperature performance: 5083 maintains toughness down to -196 °C, making it ideal for LNG carrier storage tanks.

6000 Series Marine Aluminum Alloys

These are magnesium-silicon alloys (forming Mg₂Si phases), heat-treatable (e.g. T6 temper), and offer a balanced combination of strength, formability, and surface finishing compatibility. Corrosion resistance is good but slightly lower than 5000 series.

Typical Marine Applications and Grades

6061: A versatile alloy with good mechanical properties, corrosion resistance, and excellent weldability. Used for marine components, structural frames, and even automotive parts.

6063: Softer and lower in strength than 6061, but ideal for extruding complex shapes with high surface quality. Excellent for anodizing. Used in railings, window and door frames, decorative structures.

6082: The strongest of the 6000 series, particularly suitable for structural applications, welding, and machining. Commonly used in high-speed vessel components and marine plates.

Advantages in Application

Processing adaptability: Excellent for extrusion, enabling complex cross-sectional profiles (e.g. hollow masts, streamlined gangways).

Surface treatment: Outstanding anodizing and coloring capability, improving aesthetics and wear resistance.

Lightweight: Density of just 2.7 g/cm³, reducing superstructure weight by over 50% compared to steel.

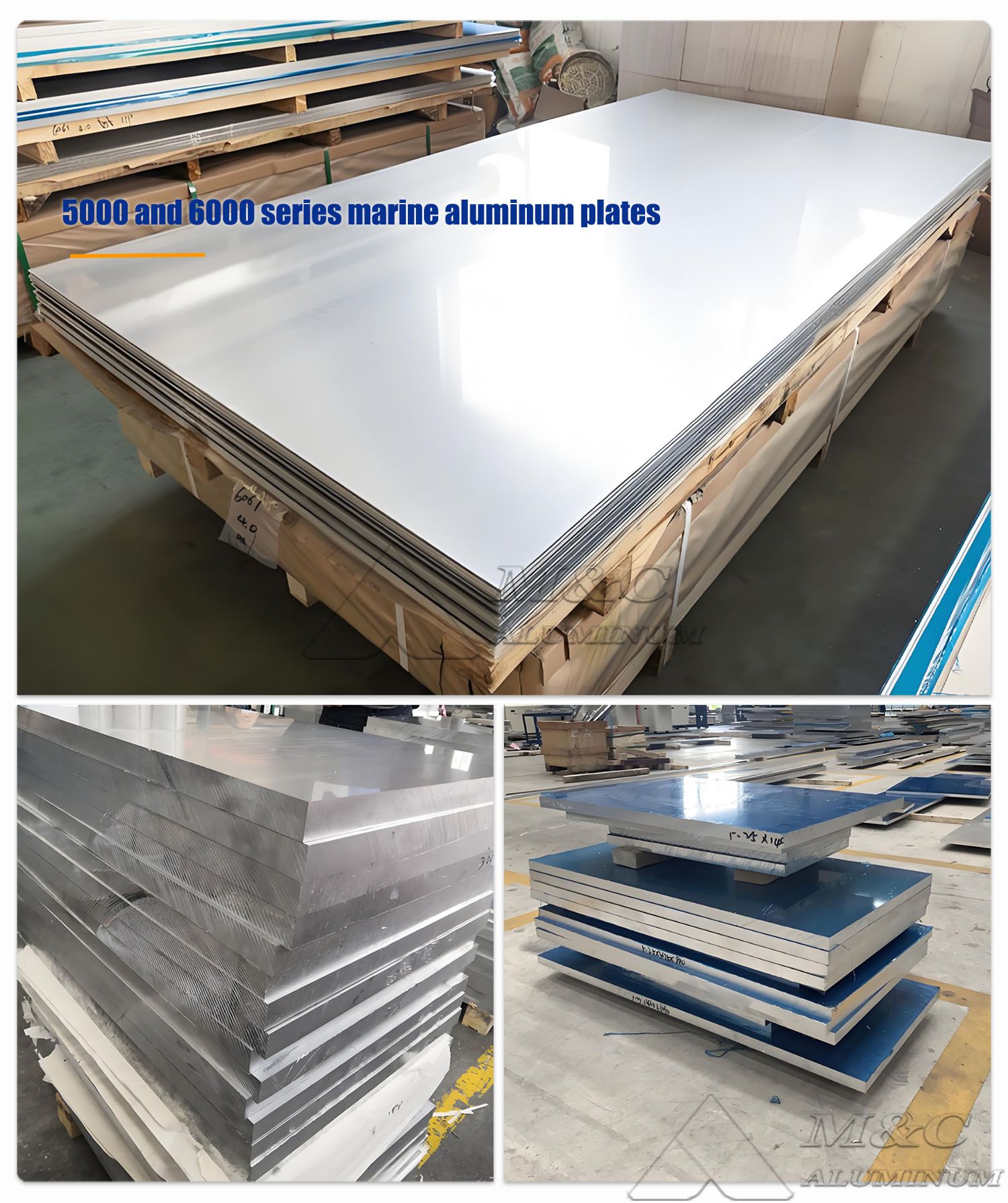

Expert View: 5000 and 6000 Series as the "Best Combination"

Industry experts widely recognize that 5000 and 6000 series alloys are not simple substitutes, but complementary solutions.

5000 series alloys (magnesium-based) are renowned for excellent seawater corrosion resistance and superior weld integrity, making them the first choice for hulls, decks, and storage tanks. However, high magnesium content can increase susceptibility to stress corrosion cracking, which must be mitigated via specific tempers (like H116 and H321).

In contrast, 6000 series alloys (magnesium and silicon) can be heat-treated for higher strength and hardness. They strike a balanced combination of strength, formability, and corrosion resistance, while offering superior stress corrosion cracking resistance. This makes 6000 series alloys ideal for extruded profiles, frames, and internal structural components—though welding can reduce strength in the heat-affected zone.

MC Aluminum: Professional Marine Aluminum Plate Manufacturer

As a specialist marine aluminum plate supplier, MC Aluminum offers a full range of 5000 series and 6000 series marine-grade aluminum plates with stable quality and classification society certifications.

In addition, we also manufacture marine aluminum extrusions, aluminum pipe fittings, and other components. Our products are exported globally, with sample availability, direct factory pricing, and reliable after-sales service.

Original Source: https://www.marinealum.com/a/5000-and-6000-series-marine-aluminum-alloy-plates.html

Tag: marine aluminum plate marine aluminum alloy plate marine-grade aluminum sheet 5000 series marine aluminum alloy 6000 series marine aluminum alloy 5000 series aluminum plate 6000 series marine aluminum sheet marine aluminum plate manufacturer