Marine-grade extruded aluminum round tube (seamless tube) is widely used in marine engineering, shipbuilding and related high-strength and anti-corrosion scenarios due to its excellent performance and characteristics.

High-precision aluminum round tubes made by extrusion process have seamless and gapless structures, usually using corrosion-resistant and high-strength aluminum alloy materials (such as 5 series and 6 series aluminum alloys). It has excellent corrosion resistance, fatigue resistance, salt spray resistance, and meets the long-term use requirements in marine environments.

Commonly used aluminum alloy materials include

1.5 series aluminum alloy (such as 5083, 5052)

1. Features: Aluminum-magnesium alloy with high strength and excellent corrosion resistance.

2. Application: Suitable for parts immersed in seawater for a long time, such as hull structures, marine equipment support pipes, etc.

2.6 series aluminum alloy (such as 6061, 6063)

1. Features: Aluminum-magnesium-silicon alloy, with high strength and good processability.

2. Application: Suitable for structural parts that require high strength and precision processing, such as ship masts and load-bearing frames.

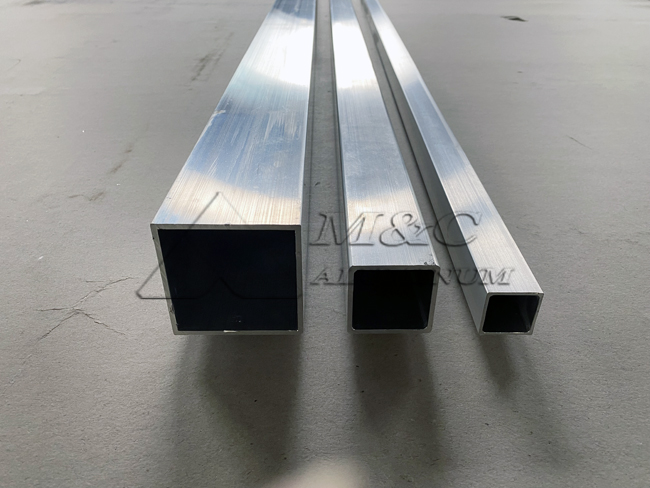

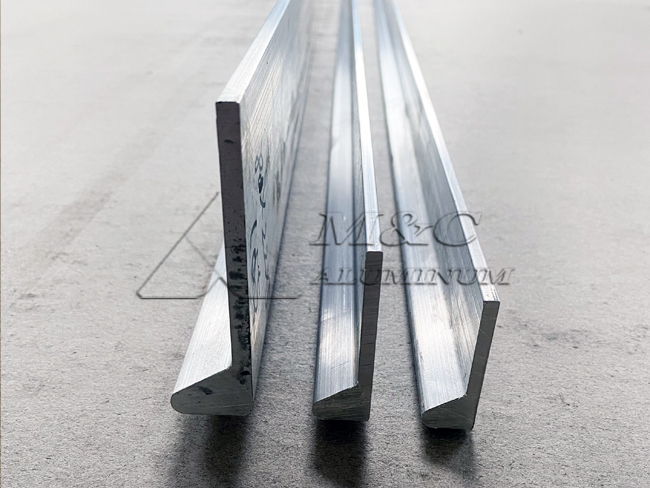

Marine aluminum round tube specifications

| Alloy | 5083, 5086, 5052, 5059, 6061, 6063, 6082 |

| Temper | H111/H112, T5/T6 |

| Certification | BV /DNV /ABS/Lioyds |

| Thickness | 3mm---50mm |

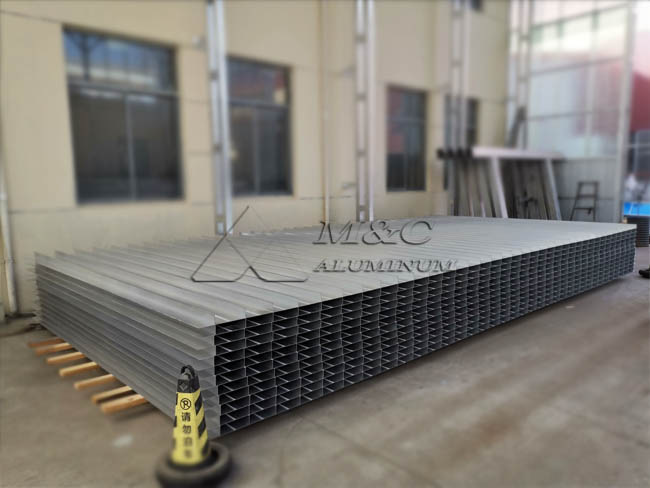

Manufacturing process

1.Extrusion process: The aluminum alloy billet is extruded into a tube of the required shape and size through an extruder, while ensuring the smoothness and seamlessness of the inner and outer walls of the tube.

2.Heat treatment: The extruded tube is heat treated to improve its strength and hardness, while eliminating internal stress and improving the stability of the tube.

3.Surface treatment: The pipe can be oxidized, sprayed and other surface treatments as needed to improve its corrosion resistance and aesthetics.

Performance characteristics of marine aluminum profiles

1. Excellent corrosion resistance: Aluminum alloy with surface treatment can resist seawater corrosion.

2. High strength and light weight: High strength and light weight, it is an ideal substitute for steel.

3. Excellent sealing: Seamless structure, high air tightness and water tightness, suitable for deep sea or high pressure environment.

4. Good processing performance: Good ductility, easy cutting, welding and surface treatment.

5. Strong fatigue resistance: Can resist frequent vibration and impact in the marine environment and extend life.

6. High safety: Small elastic modulus, large ability to absorb impact stress, and greater safety.

7. Environmentally friendly and recyclable: Aluminum waste is easy to recycle and can be recycled.

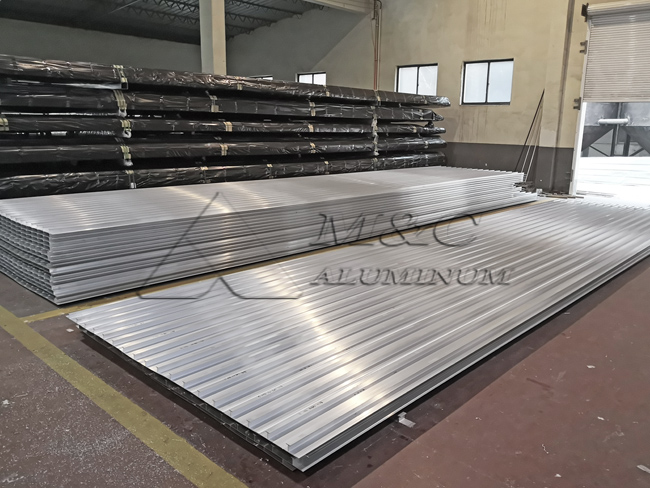

Application fields of marine-grade extruded aluminum profiles

Marine engineering: Marine-grade extruded aluminum tubes and seamless tubes are widely used in offshore platforms, submarine pipelines, offshore wind power generation and other fields as key components for conveying fluids and supporting structures.

Shipbuilding: Used to manufacture piping systems, cooling systems, drainage systems, etc. on ships to ensure the stable operation of ships in the marine environment.

Other fields: It can also be used to manufacture pipes and accessories in the fields of seawater desalination equipment and marine aquaculture equipment.

The marine-grade extruded aluminum round tubes (seamless tubes) produced by MC Aluminum have become ideal structural materials in the marine environment for their gap-free, corrosion-resistant, high-strength, and lightweight characteristics. Both performance and processing adaptability can meet the stringent requirements of marine applications, especially in high humidity, high salt, and high pressure environments.