In the field of shipbuilding, the choice of materials directly affects the performance, durability and economy of the ship. As a typical aluminum-magnesium alloy, 5083 aluminum plate has become an indispensable material in modern shipbuilding with its excellent corrosion resistance, high strength and good welding performance. Especially in the face of high-salt and high-humidity marine environment, 5083 aluminum plate provides reliable guarantee for the stability and efficiency of ships with its superior corrosion resistance and lightweight characteristics.

5083 aluminum plate, which belongs to the 5 series aluminum-magnesium alloy, is a typical rust-proof aluminum alloy. It is currently widely used in ships and yachts, with medium and thick aluminum plates being the most commonly used. The common states are H111, H112, H116, and H321. It is an aluminum alloy material commonly used by domestic and foreign shipbuilding companies.

Common states of 5083 marine aluminum plate:

1.H111 state

Features: After slight work hardening, no annealing treatment is performed, with certain strength and good toughness.

Application: Commonly used for parts with moderate strength requirements and certain processing and corrosion resistance, such as hull shells.

2..H112 state

Features: Suitable for the state of processing after hot rolling of ingots, with good comprehensive performance.

Application: Suitable for marine parts that do not require further strengthening but require higher corrosion resistance.

3. H321 state

Features: After work hardening treatment and stabilization annealing (usually used for hot-formed products), it has high strength and excellent corrosion resistance.

Application: Widely used in parts with strong load-bearing capacity such as hull frames, especially suitable for seawater environments.

4. H116 state

Features: After special work hardening treatment, it has higher corrosion resistance, especially in marine environments.

Application: Suitable for hulls, decks and other key structural parts that require high strength and corrosion resistance.

Summary:

Among them, 5083-H111 state is more inclined to forming processing performance; 5083-H116 state and 5083-H321 state are more suitable for high strength and corrosion resistance requirements of marine environment. Users can choose the appropriate state according to actual application requirements.

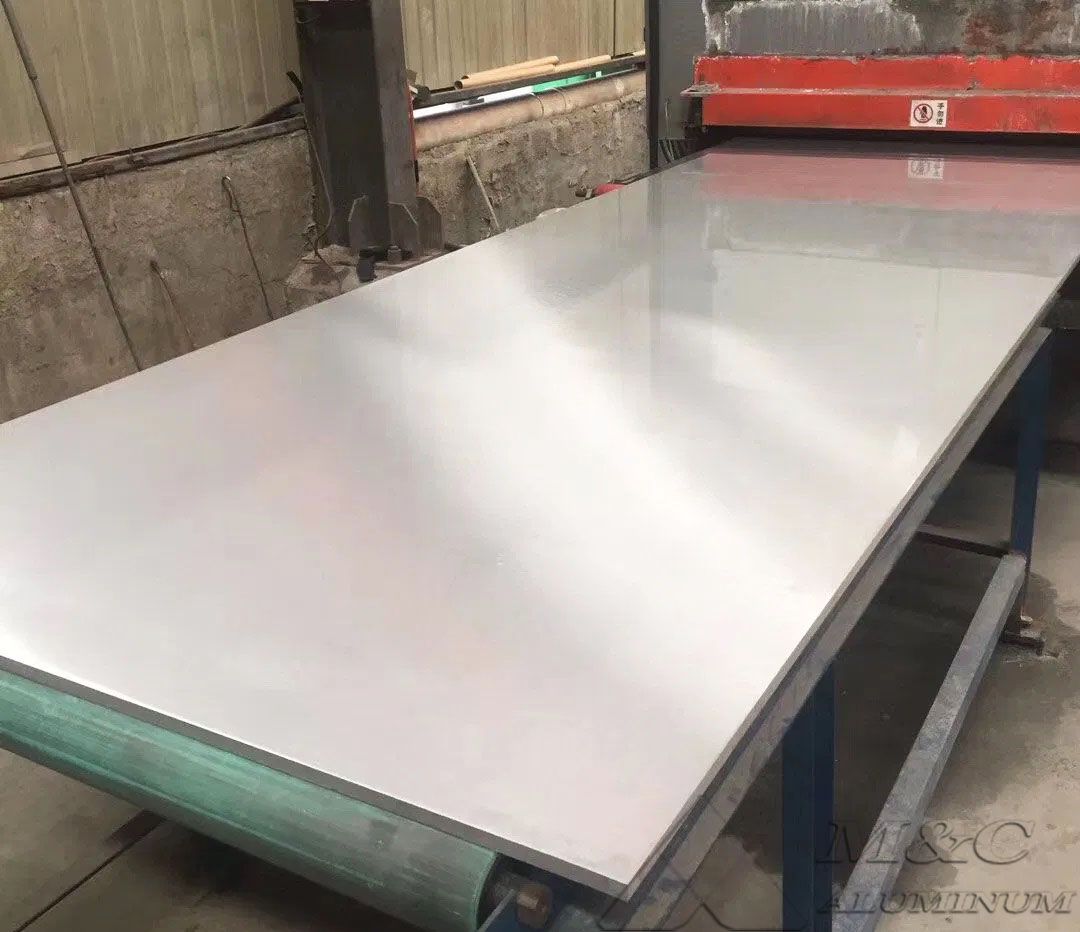

5083 marine grade aluminum plate specifications:

| Alloy | 5083 |

| Temper | H111, H112, H116, H321, etc |

| Thickness | 3-50mm |

| Width | 100-2650mm |

| Length | 100-16000mm |

| Packaging | fumigation-free wooden pallet + waterproof cloth + waterproof protective film + PE |

5083 marine grade aluminum plate features:

1. Excellent corrosion resistance: anti-corrosion of seawater and industrial environment, suitable for high humidity and high salt environment.

2. High strength: Although it cannot be heat treated, the strength can be improved by cold working hardening.

3. Excellent welding performance: supports a variety of welding methods, and has good strength and corrosion resistance after welding.

4. Good processing and forming performance: suitable for bending, stamping, stretching and other processes, easy to manufacture hulls and internal components.

5. Low density and lightweight: The density is lower than traditional steel, which helps to reduce weight, improve fuel efficiency and speed.