In recent years, with the rapid development of domestic and foreign shipbuilding industry, reducing the weight of the hull, increasing the speed of the ship, and seeking aluminum alloy materials to replace steel parts have become important issues facing the aluminum processing industry and shipbuilding industry. 6082 marine grade aluminum profile has medium strength and good corrosion resistance, and is light in weight, making it an ideal material for manufacturing high-speed ship components.

Unique advantages of 6082 aluminum alloy

6082 alloy ship profile belongs to Al-Mg-Si series heat-treatment-strengthened aluminum alloy, with medium strength and good welding performance and corrosion resistance, making it an ideal material for shipbuilding. Compared with traditional steel, 6082 aluminum alloy has a lower density, which can greatly reduce the weight of the hull, thereby improving the speed and fuel economy. In addition, its excellent salt spray corrosion resistance can effectively resist the erosion of the marine environment.

6082 aluminum alloy specifications

| Alloy | 6082 |

| Temper | T3, T4, T5, T6 |

| Size | Conventional profile thickness 0.8~5.0mm, length 3m~6m or customized; Anodized protective film thickness 8~25um, powder spraying 40~120um. |

| Surface | anodizing, powder coating, polishing, etc. |

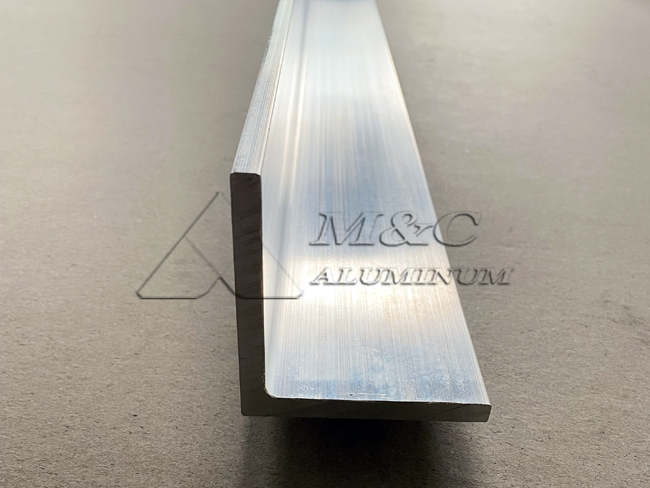

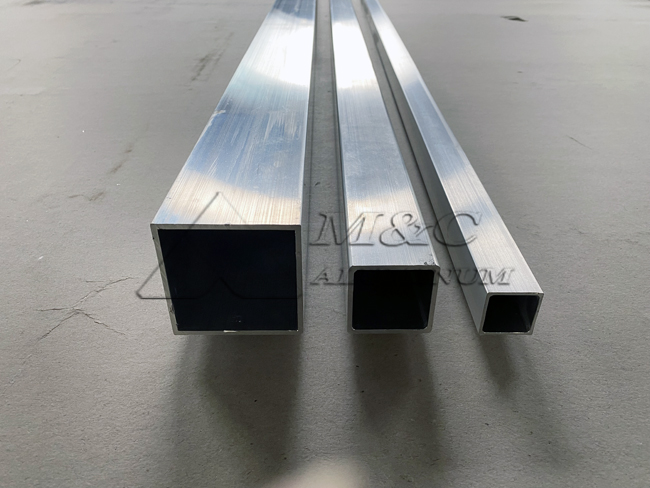

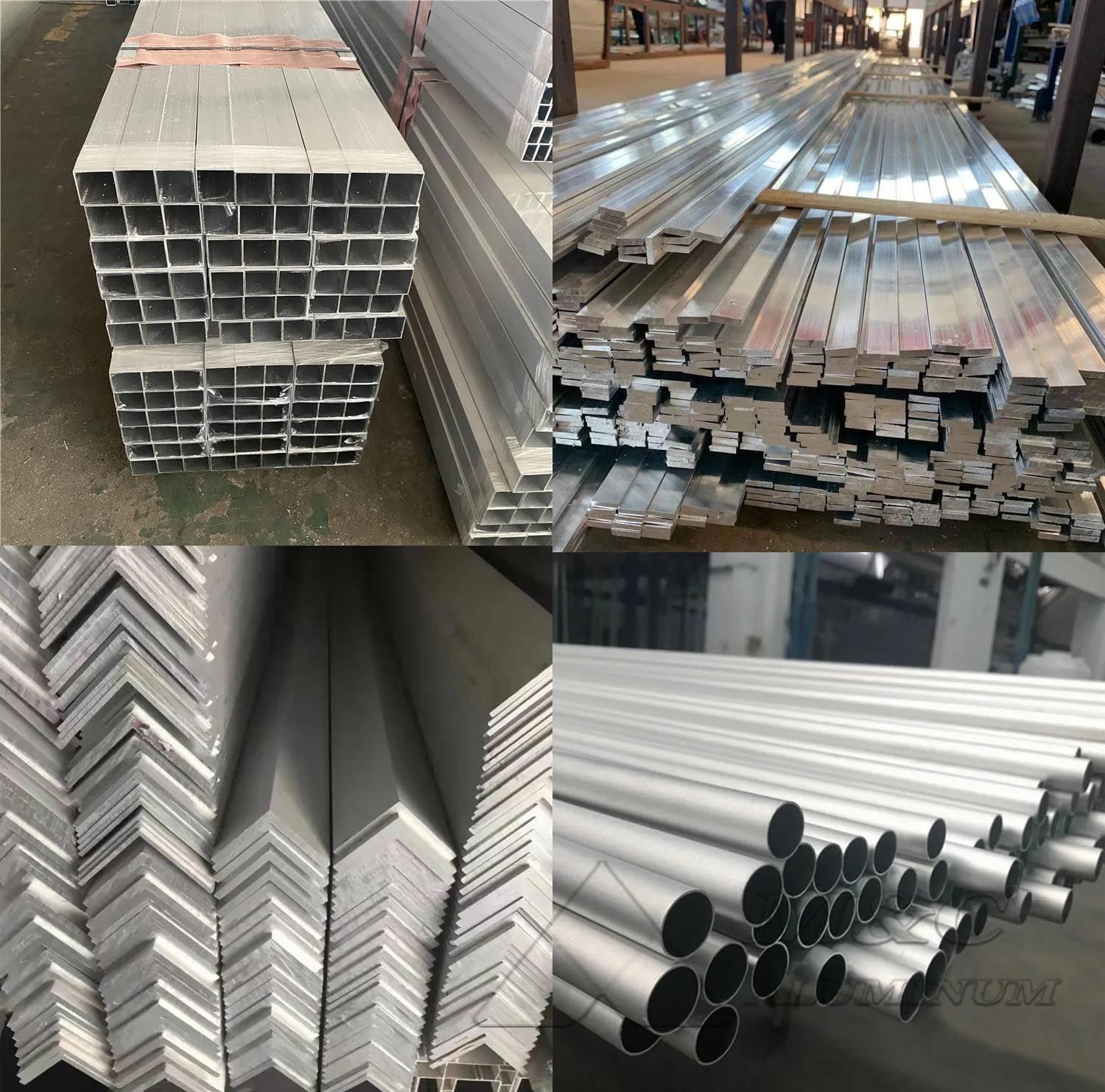

| Shape | square, tube, T-type, rod, I-shaped, angular aluminum, aluminum trough, etc. |

| Certificate | CCS, BV, LR, ABS, DNV-GL |

| Application | marine aluminum profile, ship aluminum profile, yacht aluminum profile |

6082 Aluminum alloy Chemical composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 6082 | 0.7-13. | 0.5 | 0.1 | 0.4-1.0 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | remainder |

6082 extruded aluminum profile production process for shipbuilding

1. Melting and ingot casting

Select high-purity aluminum ingots, add precise proportions of alloy elements such as magnesium, silicon, and manganese, and melt them in a high-temperature furnace to form a uniform aluminum liquid. After refining to remove impurities, the aluminum liquid is cast into ingots to provide basic materials for subsequent processing.

2. Homogenization treatment

The ingot is subjected to high-temperature homogenization annealing treatment to make the elements in the alloy more uniform, eliminate casting stress, and improve the extrusion performance and mechanical properties of the finished product.

3. Extrusion molding

The ingot is heated to 450-500°C and extruded through a pre-designed die in an extruder. The die design needs to be based on the use requirements of the ship profile to ensure the accuracy and surface quality of the product.

4. Heat treatment strengthening

The extruded profile is subjected to T6 heat treatment (solid solution treatment + artificial aging) to greatly improve the material strength by precipitating strengthening phases. The heat treatment process requires precise control of temperature and time to ensure the performance stability of the product.

5. Surface treatment

In order to further improve the corrosion resistance and appearance quality of the profile, anodizing or spraying processes are often used to form a dense protective layer on the surface of the profile to meet the long-term use requirements of ships in marine environments.

Technical requirements for 6082 extruded aluminum profiles

1. Chemical composition: strictly control the content of major alloying elements such as Si, Mg, and Fe to ensure stable alloy performance.

2. Appearance quality: The surface should not have cracks, delamination, corrosion, oxidation inclusions, peeling, bubbles and mechanical damage, and the edges should be flat and free of burrs.

3. Mechanical properties: Tensile strength σb ≥ 310MPa, yield point σ0.2 ≥ 250MPa, elongation δ ≥ 10%

4. Environmental protection requirements: The material meets environmental protection standards, no harmful substances are released during production and processing, and it can be recycled.

5. Corrosion resistance: It has good seawater corrosion resistance to ensure long-term use in the marine environment without serious corrosion.

6. Dimensional accuracy: The size and shape accuracy of the profile must meet the design requirements to ensure the accuracy of installation and connection.

7. Welding performance: It has good welding performance and is convenient for welding and connection of ship structures.