In shipbuilding, the choice of material directly determines the structural strength, durability, and weight of the vessel. 5083 marine aluminum plate, thanks to its outstanding performance, has become one of the preferred materials for manufacturing stiffened panels.

What is a Marine Aluminum Alloy Friction Stir Welded Stiffened Panel?

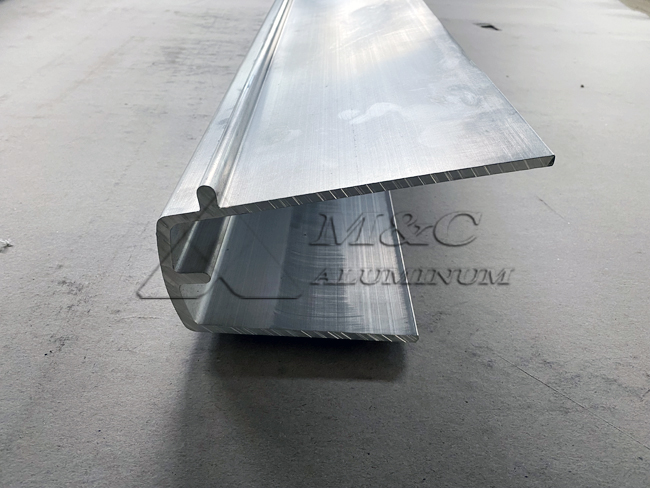

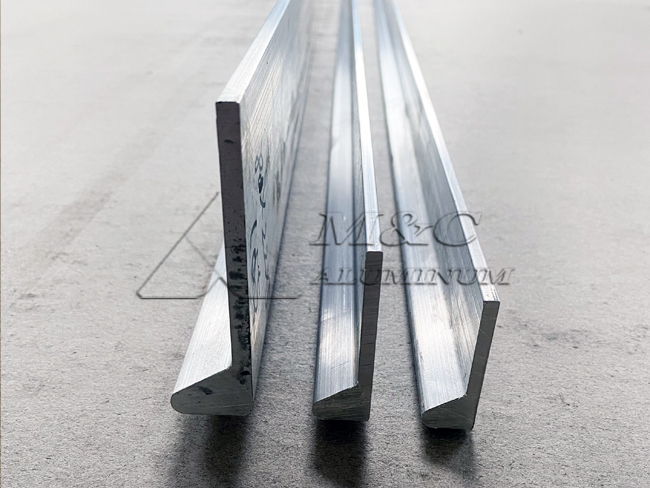

A stiffened panel is a critical structural component in shipbuilding, consisting of a skin plate and reinforcing stiffeners welded together. It significantly increases structural strength while reducing weight. Friction stir welding (FSW) joins aluminum alloy components without melting the material, resulting in joints of extremely high strength and reliability. Stiffened panels are widely used to reinforce hull plates, decks, and bulkheads, preventing buckling and deformation under external loads.

Why is Friction Stir Welding the Preferred Choice for Marine Stiffened Panels?

1. Stiffened panels form the core load-bearing structure of hulls and decks, composed of plates and stiffeners. Using 5083 aluminum plate for stiffened panels offers:

2. Enhanced Rigidity: Improves bending and torsional resistance while maintaining lightweight characteristics.

Higher Safety: Better fatigue resistance extends vessel service life.

3. Lower Maintenance Costs: Excellent corrosion resistance reduces the need for protective coatings and frequent repairs.

Reduced Defects: FSW eliminates common fusion welding defects such as porosity and hot cracking.

Tempers of 5083 Marine Aluminum Plate

5083 aluminum plate used for stiffened panels is typically supplied in O-temper or H116-temper:

O-temper (annealed): High ductility, suitable for complex bending and forming.

H116-temper: Specially stabilized for superior resistance to stress corrosion cracking, specifically developed for marine and offshore applications.

MC Aluminum ensures strict quality control of FSW panels, with each batch undergoing ultrasonic inspection, mechanical testing, and corrosion resistance evaluation, guaranteeing compliance with certifications from major classification societies such as ABS, BV, and CCS.

Main Material Choices for Marine FSW Stiffened Panels

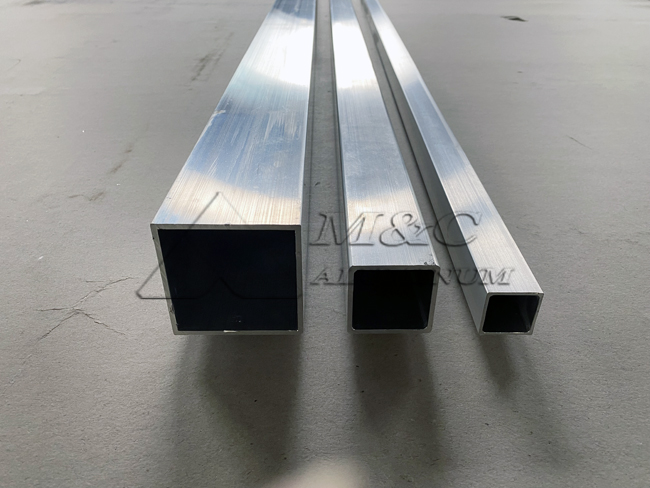

Marine FSW stiffened panels typically adopt 5XXX and 6XXX series aluminum alloys due to their corrosion resistance and mechanical strength.

5083 Aluminum Plate - The most widely used marine alloy, offering excellent seawater corrosion resistance and weldability, ideal for hull stiffened plates and decks.

5052 Aluminum Plate - Strong corrosion resistance and exceptional ductility, suitable for medium-strength and deep-drawing parts, commonly used for interior panels or secondary structural elements.

5456 Aluminum Plate - Higher magnesium content than 5083, providing greater strength, suitable for high-speed vessels and naval ships requiring higher structural strength.

6061 Aluminum Plate - High strength and heat-treatable, suitable for structural parts requiring both strength and light weight, though its corrosion resistance is slightly weaker than 5XXX alloys.

6082 Aluminum Plate - Among the 6XXX alloys, it offers better corrosion resistance with high tensile strength, widely used in deck frameworks and bulkheads.

Advantages of Aluminum Alloy Stiffened Panels Compared with Traditional Steel

Compared with steel, aluminum alloy FSW stiffened panels provide significant weight reduction - aluminum density is only one-third that of steel, improving payload capacity and fuel efficiency. Alloys such as 5083 and 5052 offer outstanding seawater corrosion resistance, lowering maintenance costs and extending service life. With superior weldability and formability, aluminum stiffened panels also enable more flexible structural designs and advanced manufacturing processes, making them widely adopted in modern shipbuilding.

As an experienced marine aluminum processor, MC Aluminum has introduced large-scale FSW equipment capable of producing panels up to 15 meters in length, 3.3 meters in width, and thicknesses ranging from 2 mm to 12 mm, with full customization available. Using high-precision FSW technology, we achieve defect-free weld seams on 5083, 5052, and 6061 aluminum plates, ensuring optimal strength and corrosion resistance. Our FSW panels are certified by CCS, BV, LR, and other major classification societies, fully meeting shipbuilding requirements.

Original Source: https://www.marinealum.com/a/5083-marine-aluminum-plate-for-stiffened-panels.html

Tag: marine aluminum alloy friction stir welded stiffened panel aluminum stiffened panel aluminum reinforced plates for ships marine FSW stiffened panel stiffened aluminum profiles 5083 marine stiffened panel marine FSW panel 5083 marine aluminum plate