In the field of shipbuilding, aluminum sheet is a lightweight and high-strength material, among which 5 series aluminum sheet and 6 series aluminum sheet are two common materials. They are widely used in key parts such as hull structure, deck, cabin, etc.

Basic concepts of 5 series marine aluminum sheet and 6 series marine aluminum sheet

5 series aluminum sheet

Definition: 5 series aluminium sheet mainly uses magnesium as the main alloying element, and the magnesium content is usually between 3% and 5%, so it is also called aluminum-magnesium alloy.

Representative grades: 5052, 5083, 5754, 5383, etc.

Features:

(1) Low density, high tensile strength, high elongation, and good fatigue strength.

(2) Excellent corrosion resistance, especially suitable for use in harsh environments such as seawater.

(3) Relatively weak processing formability, but its mechanical strength can be improved through work hardening.

6 series aluminum sheet

Definition: 6 series aluminium plate uses magnesium and silicon as the main alloying elements, and the ratio of magnesium to silicon determines its performance characteristics. The main strengthening phase is Mg2Si, which can be strengthened by heat treatment.

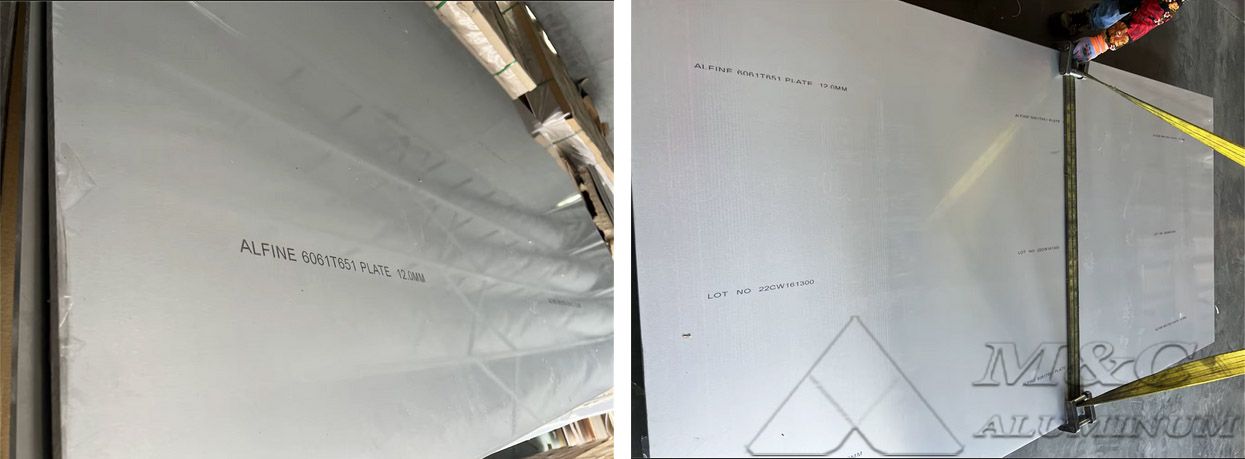

Representative grades: 6061, 6082, 6083, etc.

Features:

(1) It has medium strength, good plasticity and excellent corrosion resistance.

(2) It has excellent weldability and no tendency to stress corrosion cracking.

(3) It has good processability and can be strengthened by heat treatment.

Marine aluminum sheet specifications

| Alloy | 5052, 5083, 5383, 5754, 6061, 6062, 6083, etc |

| Temper | H112, O, H32, H111, T6, T5, T651, etc |

Thickness | 3-50mm |

| Width | 100-2650mm |

| Length | 1000-16000mm |

| Application | yachts, fishing boats, speedboats, etc. |

Performance comparison between 5 series aluminum sheet and 6 series aluminum sheet

| Performance Indicators | 5 series aluminum sheet | 6 series aluminum sheet |

| Corrosion resistance | Extremely strong, suitable for long-term contact with seawater and humid environments. | Stronger, but not as good as the 5 series, surface treatment is required to improve performance in marine environments. |

| Strength | Higher strength, but lower than 6 series, usually suitable for medium strength requirements. | Higher strength, suitable for parts with higher structural requirements. |

| Weldability | Excellent welding performance, good mechanical properties after welding. | General weldability, heat treatment after welding may cause performance changes. |

| Processability | Good ductility, suitable for cold processing, such as bending and stretching. | Excellent machining performance, suitable for precision processing such as turning and milling. |

| Heat treatment | Cannot be strengthened by heat treatment, mainly relies on cold working hardening. | Strength and hardness can be improved by heat treatment (T6 state). |

| Weight | Relatively light, suitable for ship structures with high weight requirements. | Slightly heavier, but stronger, suitable for load-bearing parts. |

Marine-grade aluminum sheet application areas

1.5 series aluminum sheet application

(1) Hull and deck

For example, 5083 aluminum sheet has excellent corrosion resistance and medium-to-high strength. It is widely used in marine hull and deck materials, especially for fishing boats, passenger ships and other occasions that need to be in contact with seawater for a long time.

(2) Fuel tank and cabin lining

5754 aluminum sheet is used for fuel tanks, cabin linings and other parts that require corrosion resistance due to its good oxidation resistance and formability.

2. Application of 6 series aluminum sheet

(1) High-strength structural parts

6061 aluminum sheet is often used for ship frames, support beams and other structural parts due to its high strength and excellent processability, especially in high-speed boats and yachts.

(2) Complex mechanical parts

6082 aluminum sheet is suitable for ship parts that require complex processing, such as cabin equipment brackets, ship control system components, etc.

How to choose between 5 series and 6 series in shipbuilding

1. For ship parts that require high strength, good corrosion resistance and light weight, such as instruments and sheet metal parts, 5 series aluminum sheets are a more suitable choice.

2. For ship parts that require good processing formability, excellent weldability and high requirements for strength and corrosion resistance, such as some complex structural parts or equipment parts, 6 series aluminum sheets may be more suitable.

In summary, when selecting marine aluminum sheets, 5 series or 6 series aluminum sheets should be selected according to the specific use environment and needs to ensure the performance and safety of the ship.