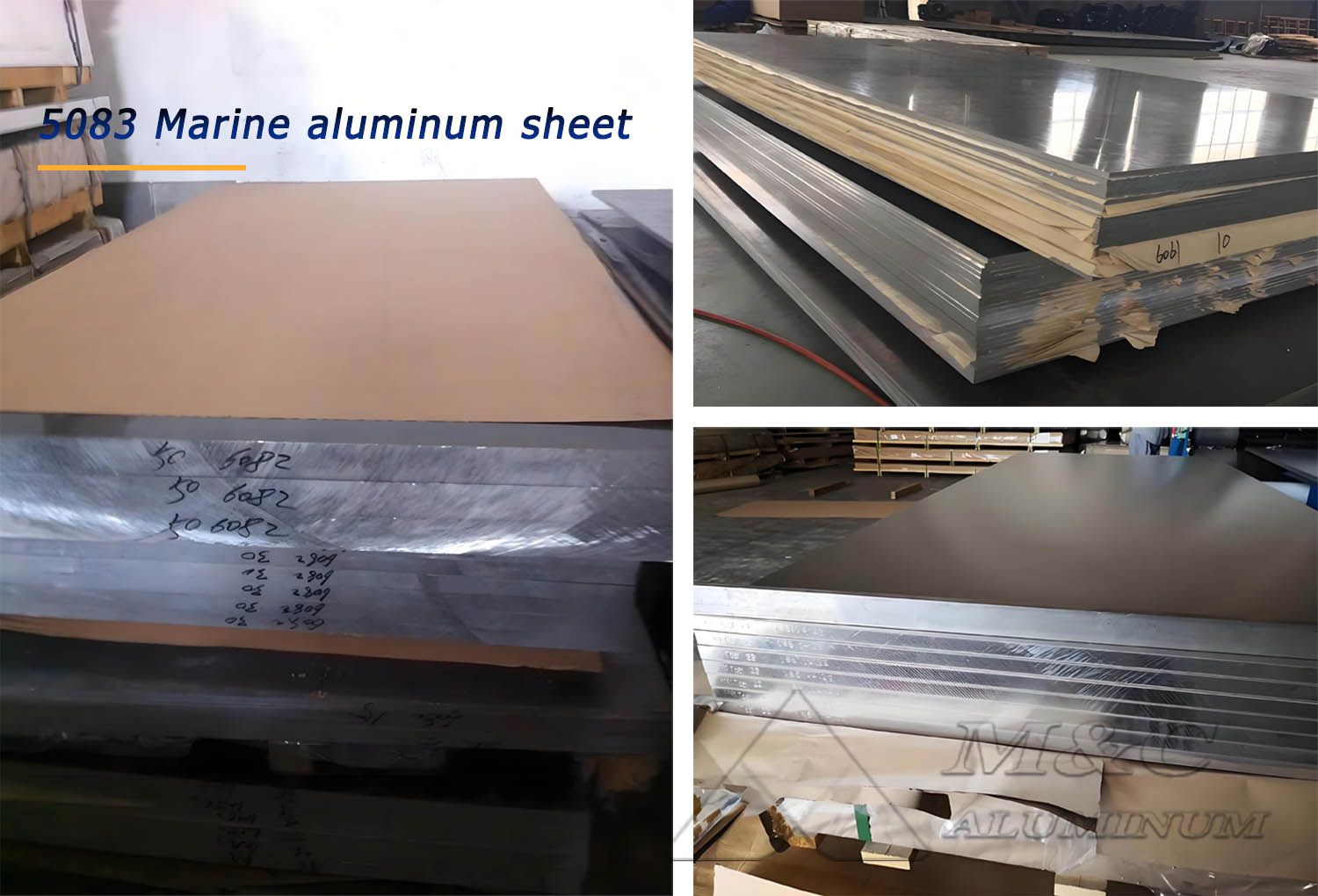

MC Aluminum produces 5083 marine-grade aluminum plates with a typical thickness range of 3–50mm, widths from 1000–3100mm, and lengths up to 1000–13000mm. These size specifications meet the manufacturing needs of various ship structures and components.

Common tempers for 5083 marine aluminum sheets include O, H32, H34, H22, H24, H116, H111, etc. The temper affects properties such as hardness, strength, and machinability. It’s essential to choose the appropriate temper based on the specific part and performance requirements in shipbuilding.

Technical Features of 5083 Marine Aluminum

1.Corrosion Resistance: As an Al-Mg alloy, with magnesium as the main element, 5083 has excellent corrosion resistance in marine environments, effectively resisting seawater corrosion and prolonging vessel lifespan.

2.Weldability: Excellent weldability compatible with multiple welding methods (e.g., TIG, MIG), ensuring strong and tight welds, improving structural integrity and sealing.

3.Strength: Medium strength that can be enhanced through work hardening. Different thicknesses offer varying strength levels, with thicker plates able to withstand higher loads.

4.Formability: Good cold-working performance, easily shaped into different forms as required by ship structure designs.

Specifications:

| Alloy | 5083 |

| Tempers | H116, H111, H321, H34, H12, H112, etc. |

| Thickness | 3–50mm |

| Width | 1000–2650mm |

| Length | 1000–16000mm |

| Type | Sheet |

| Applications | Hull sides, bottom plates, ribs, bulkheads, wheelhouse funnels, decks, bulwarks |

| Certificates | ABS, DNV, LR, etc. |

| MOQ | 1–3 tons |

5083 Aluminum Alloy Chemical Composition (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

Mechanical Properties of 5083 Marine Aluminum Plates

| Temper | Yield Strength Rp0.2 | Tensile Strength Rm | Elongation A50 | Bend Test (180°) | Applicable Standards |

| O | ≥145 MPa | ≥275 MPa | ≥20% | Pass (≤1t) | ASTM B209, GB/T 6892 |

| H111 | ≥170 MPa | ≥290 MPa | ≥17% | Pass (≤1.5t) | ASTM B928, EN 485 |

| H112 | ≥125 MPa | ≥275 MPa | ≥12% | Suitable for thick plates, easy to weld | ASTM B928 |

| H116 | ≥215 MPa | ≥305 MPa | ≥10% | Pass (≤1.5t) | ASTM B928, CCS, DNV |

| H321 | ≥240 MPa | ≥315 MPa | ≥10% | Pass (≤1.5t) | ASTM B928, BV, CCS |

| F | No specific value | No specific value | No specific value | Bending not guaranteed | For non-structural parts |

Applications of 5083 Marine Aluminum

Used in ship and offshore engineering superstructures, such as hull structures and cabins. Smaller diameter aluminum tubes are used in ship systems, while larger pipes and bars are used as masts, beams, etc. To reduce weight, thinner aluminum profiles are also used in some structural components.

Common applications include LNG storage tanks, ferries, yachts, patrol boats, and other large marine superstructures, lifting platforms, and offshore drilling platforms.

MC Aluminum, as a large-scale manufacturer of marine aluminum materials, offers aluminum plates/coils,aluminum profiles, pipe fittings, FSW plates, and aluminum-steel composite panels. Available aluminum alloys include 5083, 5052, 5754, 5059, 6061, 6082, and 6063. With stable product quality, customized production, rich export experience, and short delivery times, we welcome both new and existing customers to visit our factory.