In the field of shipbuilding and offshore engineering, aluminum alloys have become ideal materials due to their lightweight, high strength, and excellent corrosion resistance. Especially when facing high-salinity, high-humidity, and highly corrosive seawater environments, the selection of materials directly determines the service life and maintenance cost of the vessel.

Among the many aluminum alloys, 5052 marine aluminum and 6061 mareine aluminumare two of the most commonly used materials for marine structures and ocean-engineering equipment. Although both belong to the aluminum-magnesium or aluminum-magnesium-silicon alloy systems, they differ significantly in chemical composition, corrosion resistance, weldability, and mechanical properties.

Challenges Faced by Marine Aluminum Plates in Ocean Environments

1. Chloride Ion Corrosion

Seawater contains a large number of chloride ions that can destroy the passive oxide film on aluminum surfaces, causing pitting corrosion, crevice corrosion, and other forms of localized corrosion.

2. Marine Atmosphere

Ocean spray creates a salt-rich atmospheric environment. A thin film of saltwater forms on metal surfaces, accelerating electrochemical corrosion.

3. Marine Biofouling

Attached marine organisms not only increase weight but may also form oxygen-concentration cells, accelerating localized corrosion.

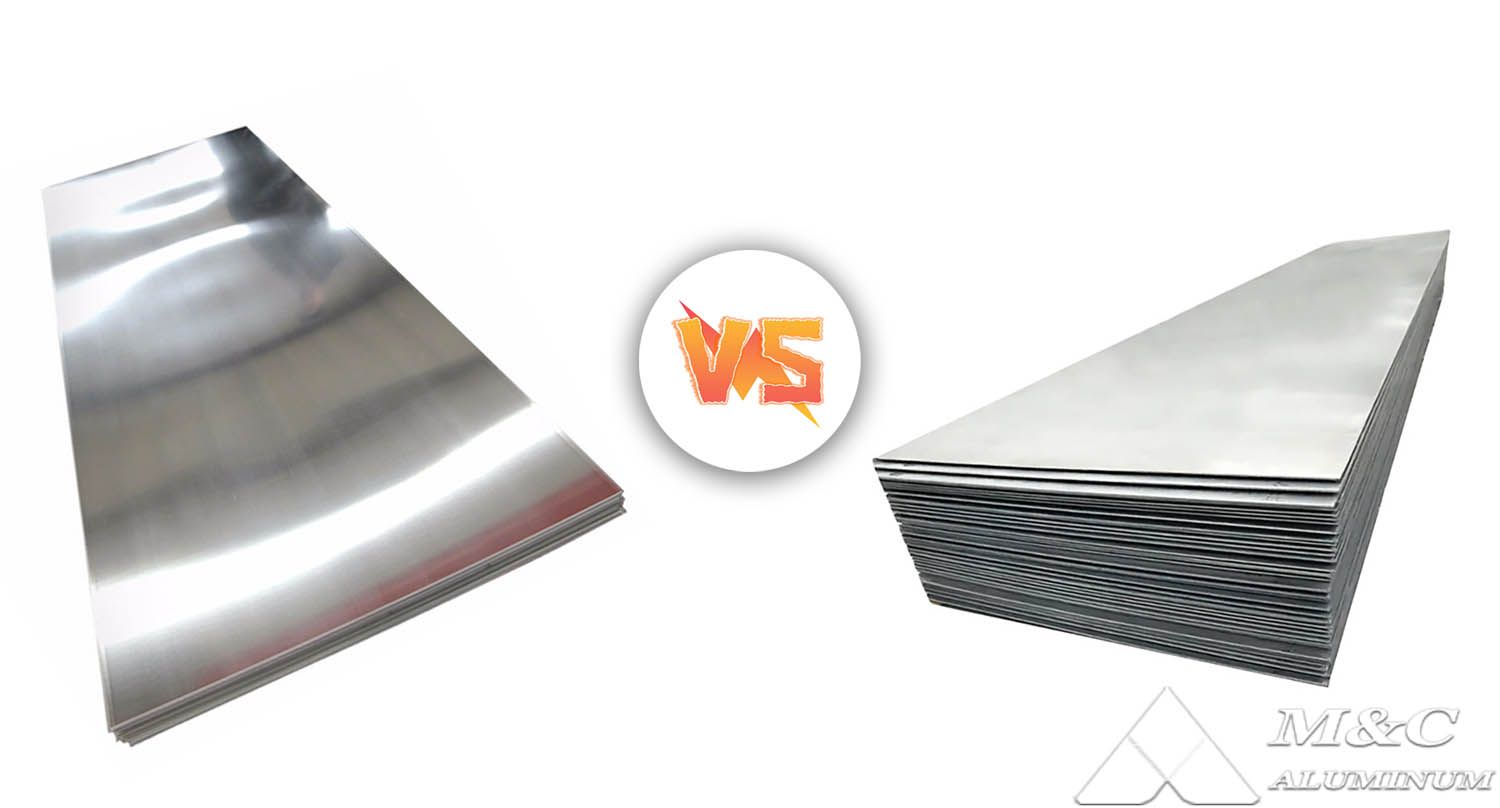

Marine Aluminum Plate: 5052 vs. 6061

1. Chemical Composition

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | remainder |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

5052 contains more magnesium, giving it stronger corrosion resistance and better weldability.

6061 contains higher silicon and copper, giving it higher strength and precipitation hardening ability, but slightly weaker corrosion resistance.

2. Mechanical Properties Comparison

| Mechanical Properties | 5052 Aluminum Alloy | 6061 Aluminum Alloy |

| Tensile Strength | 210-260 MPa | 290-310 MPa |

| Yield Strength | 130 MPa | 240 MPa |

| Elongation | 6-12% | 12-20% |

| Brinell Hardness | 61 HB | 95 HB |

| Fatigue Strength | 117 MPa | Lower than 5052 |

| Elastic Modulus | 70.3 GPa | 68.9 GPa |

From the comparison above:

For hulls, decks, and structural components, 5052 offers a better balance of corrosion resistance and workability.

6061 is more suitable for reinforcement components and load-bearing structures.

3. Corrosion Resistance

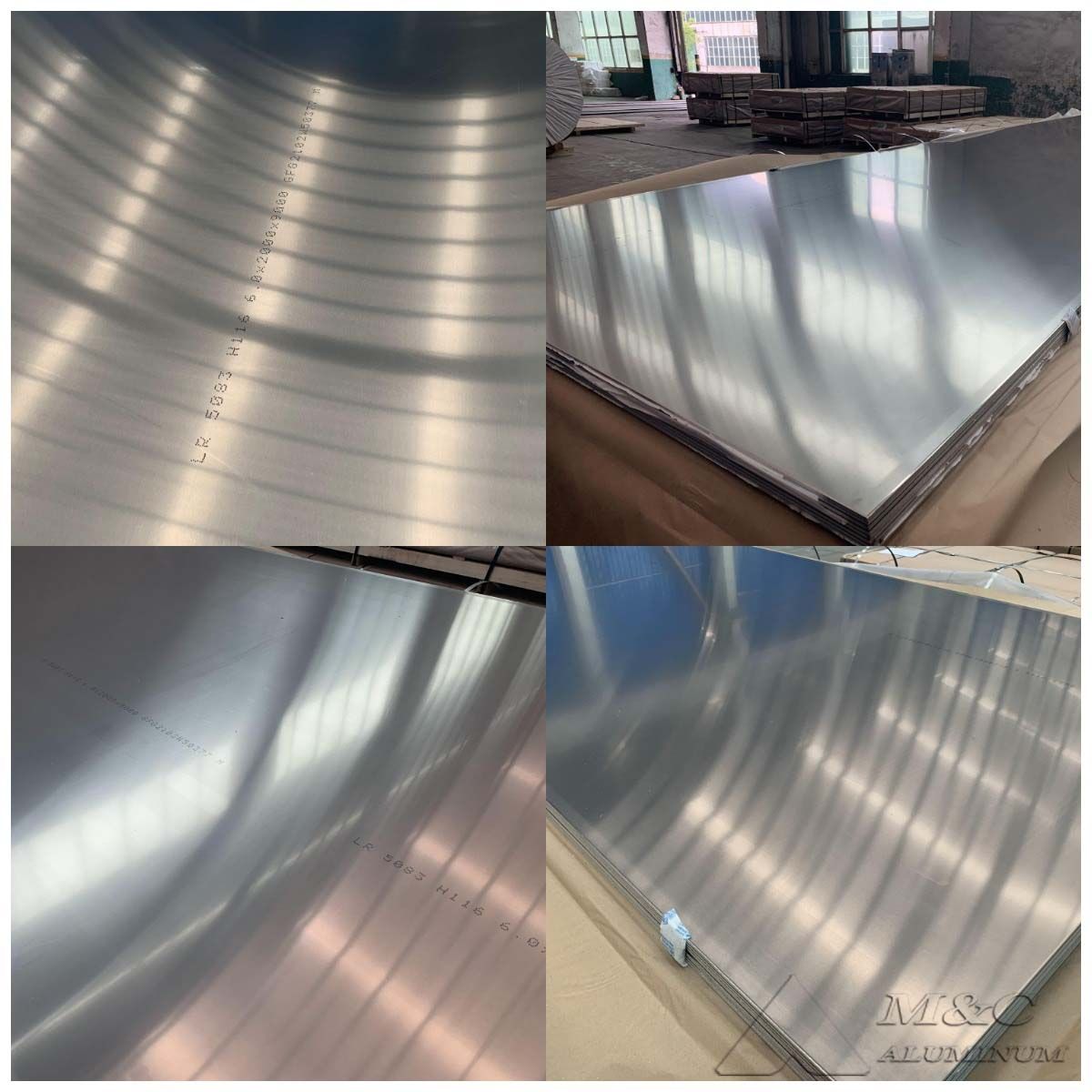

5052 aluminum alloy, with a magnesium content of about 2.5%, forms a stable and dense oxide film in seawater that effectively prevents chloride penetration.

6061 aluminum alloy, due to its copper content, is more susceptible to micro-galvanic corrosion, accelerating local oxidation.

4. Weldability

5052 can be welded using TIG or MIG methods, producing strong welds without cracking.

6061 can also be welded, but due to its Si and Cu content, it is more prone to thermal cracking and post-weld strength reduction.

5. Forming and Processing Performance

5052 has excellent cold-working properties and can withstand deep drawing, bending, and stamping.

6061 is harder and more prone to cracking or spring-back during forming operations.

6. Fatigue Resistance and Service Life

5052 has slower crack-propagation under cyclic loading and offers superior fatigue life.

6061, despite its higher initial strength, is more susceptible to crack initiation under prolonged vibration.

7. Application Fields

5052 marine aluminum sheet is widely used in ship hulls, decks, cabin structures, fuel tanks, water tanks, pressure vessels, etc., where it is in direct contact with seawater for extended periods or where high corrosion resistance is required.

6061 marine aluminum sheet has high strength but lower corrosion resistance than 5052, making it unsuitable for the main ship structure. Therefore, it is suitable for internal support frames, guide rails, machine parts, high-strength structural components, and building structures in terrestrial or freshwater environments.

8. Cost Comparison

5052 is slightly less expensive than 6061 (5%–10% lower), with more abundant supply.

6061, due to its heat-treatable strengthening capability, can be slightly more expensive in certain specifications.

Conclusion

In marine environments:

5052 marine-grade aluminum alloy is the preferred material for small and medium-sized vessels, yachts, cabin structures, and buoy equipment thanks to its outstanding corrosion resistance, weldability, and processability.

6061 aluminum alloy is more suitable for masts, structural supports, mechanical components, and applications that require higher strength but involve less direct seawater contact.

Users can select materials based on actual needs.

MC Aluminum, as a professional marine aluminum plate manufacturer, provides complete specifications of 5-series and 6-series marine-grade aluminum alloys. With high quality, factory-direct prices, and global export capability, you can purchase with confidence.

Original Source: https://www.marinealum.com/a/5052-marine-grade-vs-6061-aluminum-for-saltwater.html

Tag: 5052 marine-grade aluminum plate 6061 marine aluminum plate marine-grade aluminum alloy corrosion-resistant aluminum alloy marine aluminum material marine aluminum sheet marine aluminum manufacturer