5059 Aluminum Sheet: The Ideal Choice for Ship and Marine Vessel Manufacturing

In the field of ship and marine vessel manufacturing, material selection is critical. It must meet high-strength requirements while providing excellent corrosion resistance. As a high-strength, corrosion-resistant aluminum-magnesium alloy, 5059 marine aluminum sheet is widely used in shipbuilding, marine engineering, and high-performance vessels, making it an ideal material for the modern maritime industry.

5059 aluminum sheet is a high-strength, high-toughness, and corrosion-resistant 5-series aluminum-magnesium alloy plate composed primarily of aluminum, magnesium, manganese, zinc, and other elements. These properties make it highly applicable not only in shipbuilding and marine engineering but also in automotive manufacturing, construction, aerospace, and chemical equipment industries. Additionally, surface treatments such as anodizing, coating, and mechanical polishing can further enhance its performance and appearance.

Why Choose 5059 Aluminum Sheet for Shipbuilding?

1. Outstanding Corrosion Resistance

The marine environment is highly corrosive to metal materials. The high magnesium content in 5059 aluminum alloy provides superior resistance to seawater and humidity, effectively extending the lifespan of ships and marine structures.

2. High Strength and Lightweight

5059 aluminum sheet offers an excellent strength-to-weight ratio. While maintaining high strength, it significantly reduces weight compared to traditional steel materials. This enhances fuel efficiency, increases vessel speed, and reduces operational costs.

3. Excellent Weldability

5059 aluminum sheet is compatible with various welding techniques, including MIG and TIG welding. This ensures easy processing during shipbuilding, providing strong and reliable structural connections.

4. Superior Fatigue Resistance

Compared to other aluminum alloys, 5059 aluminum sheet exhibits better fatigue resistance, maintaining stability in long-term, high-intensity marine operations. This reduces maintenance frequency and costs.

5. Fire Resistance

5059 aluminum sheet has inherent fire-resistant properties. In the event of a fire, it can maintain its strength and stability, reducing fire hazards and enhancing the overall safety of the vessel.

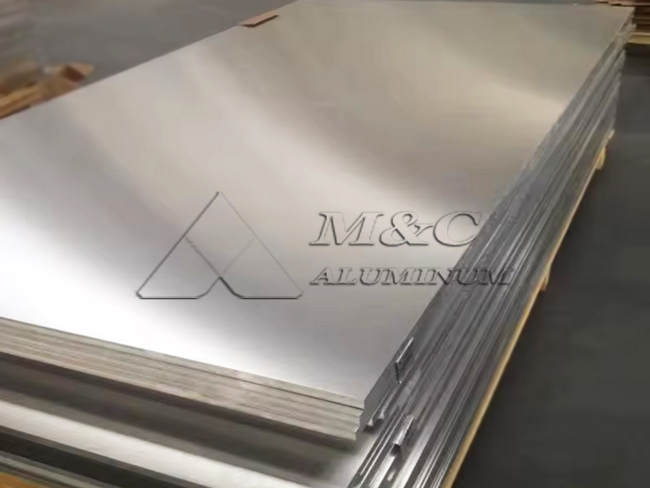

5059 Marine-Grade Aluminum Sheet Specifications

| Alloy | 5059 |

| Temper | H32, H34, H116, H321, etc. |

| Thickness | 3.0mm - 50mm |

| Width | 1000mm - 3000mm |

| Length | 2000mm - 12000mm (customizable) |

| Surface Treatment | Anodizing, coating, anti-slip pattern, etc. |

Applications of 5059 Marine Aluminum Sheet

1. Ship Hull Structure

5059 aluminum sheet is used for manufacturing hull shells, side panels, and bottom plates. These components must withstand water pressure and wave impact while ensuring strength and waterproofing.

2. Deck

As the main area for crew activities and cargo storage, decks require high strength and wear resistance. The corrosion resistance of 5059 marine aluminum prevents seawater erosion, ensuring long-term durability.

3. Bulkheads

Bulkheads separate different compartments within a ship. They require excellent strength and sealing properties. 5059 aluminum sheet can be welded into robust structures to prevent liquid leakage and gas diffusion.

4. Superstructures

Components such as the wheelhouse and crew cabins benefit from the lightweight properties of 5059 aluminum sheet. Its excellent processability ensures both aesthetic appeal and functional performance.

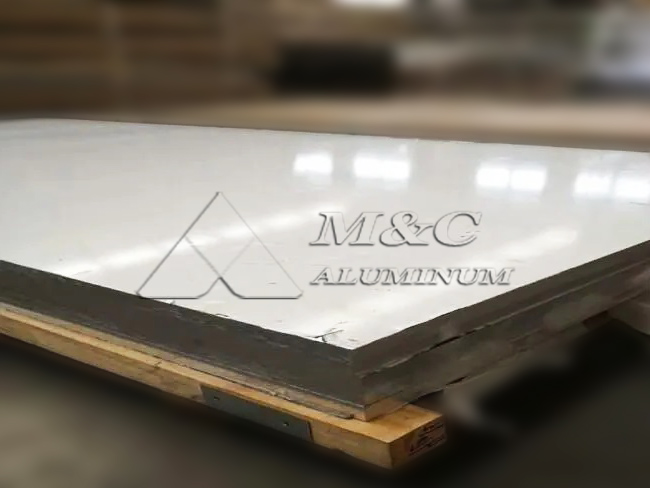

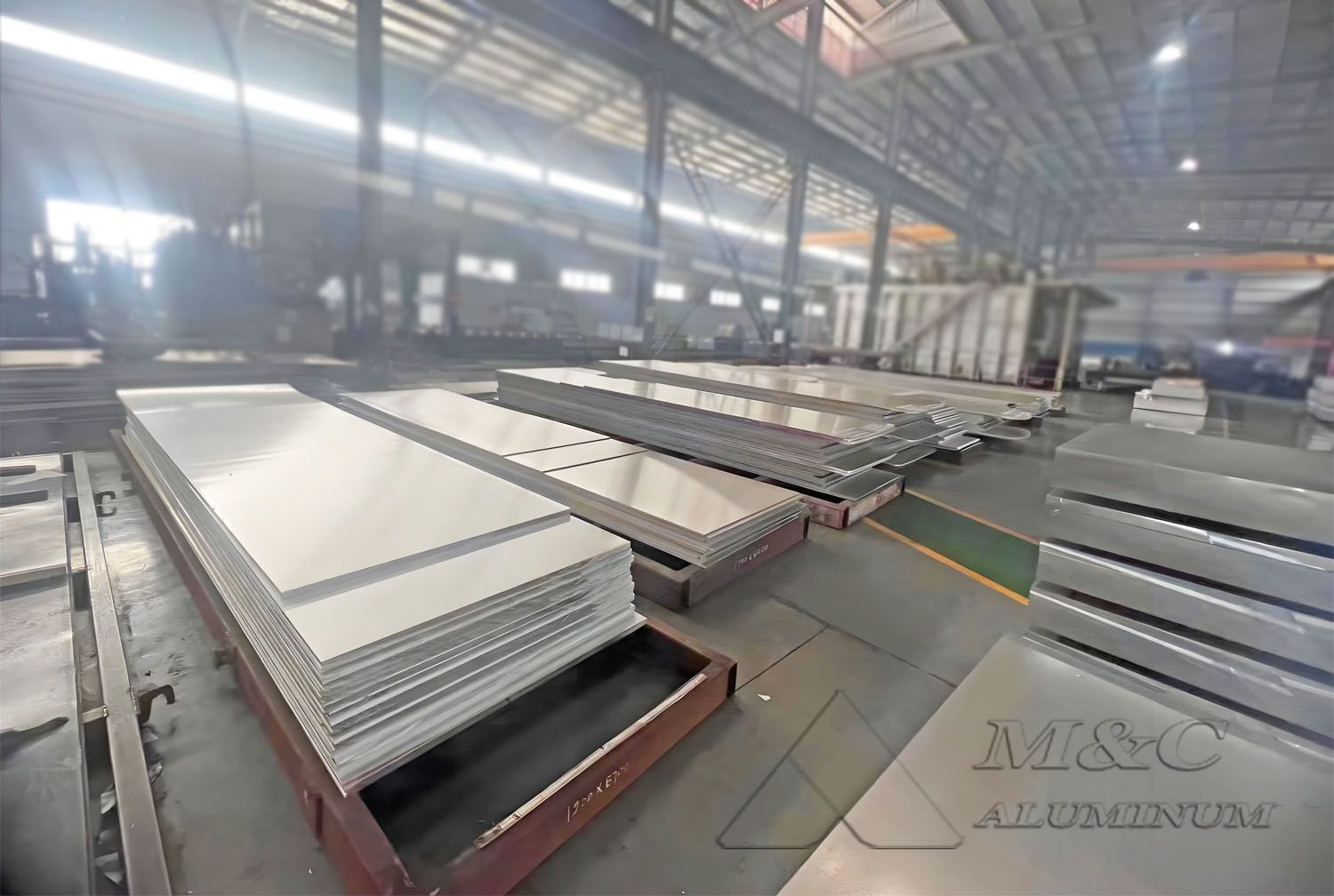

MC Aluminum: Trusted Supplier of 5059 Marine Aluminum Sheet

As a professional manufacturer of marine aluminum sheets, MC Aluminum supplies high-quality 5059 marine aluminum sheets that meet the certification standards of China Classification Society (CCS), Det Norske Veritas (DNV), and the American Bureau of Shipping (ABS). These certifications ensure the reliability and safety of 5059 aluminum sheets in marine applications.