In modern ship design, the mast is one of the critical structures, not only supporting important facilities like sails or communication equipment but also having to withstand the challenges of wind, waves, and harsh environmental conditions. Therefore, the materials for masts must possess qualities such as light weight, high strength, and corrosion resistance to ensure the stability and safety of the vessel. Aluminum alloys, especially high-performance aluminum profiles, have become the material of choice for ship masts.

Main Materials

The commonly used materials for ship mast aluminum profiles include 5083, 6061, and 6082 aluminum alloys. These alloys have excellent corrosion resistance, high strength, and good workability, making them suitable for ship use in harsh marine environments.

5083 Aluminum Alloy: This is an aluminum-magnesium alloy with low density, high strength, and excellent corrosion resistance. It is especially suitable for making mast bases and upper structures of large yachts and commercial vessels.

6061 Aluminum Alloy: Known for its good strength and corrosion resistance, it is also easy to process and weld. It is commonly used for manufacturing masts and other structural components of various types of ships.

6082 Aluminum Alloy: This alloy offers higher strength and better welding performance, making it suitable for ship masts that require higher strength. Its corrosion resistance and fatigue resistance are also outstanding, making it ideal for masts that need to bear substantial pressure and load.

Mast Marine-Grade Aluminum Profile Specifications

| Alloy | 5083, 6061, 6082, 5052, etc. |

| Thickness | 3-50mm |

| Length | 1000-16000mm |

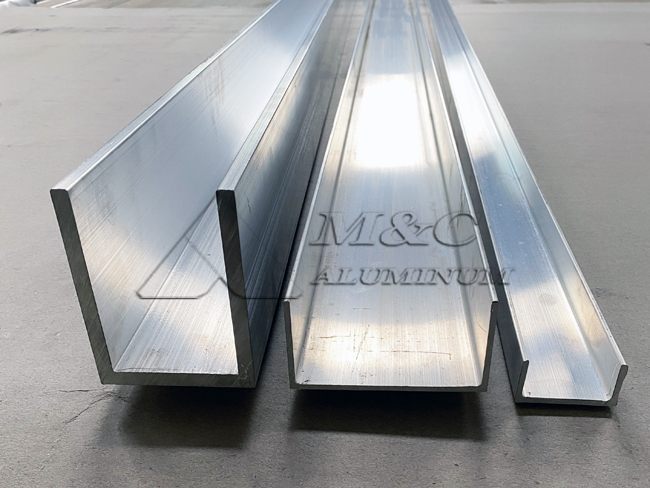

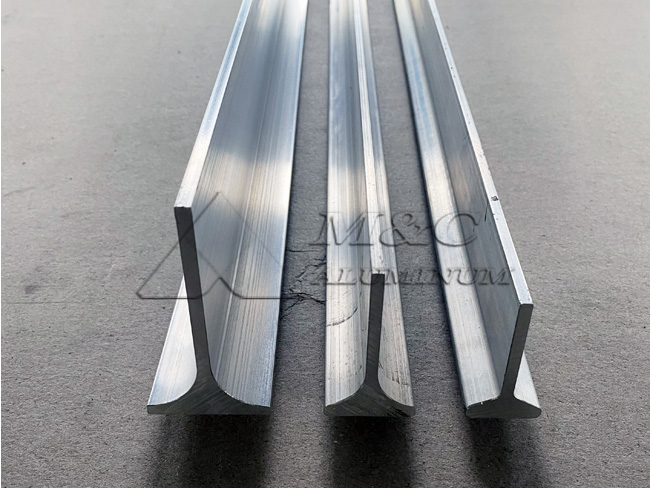

| Cross-section Shapes | U-type, H-type, T-type, L-type, etc. |

| Certifications | CCS, DNV, ABS, and other classification society certificates |

Features of Aluminum Alloy Mast Marine Profiles

1.Lightweight: The density of aluminum profiles is much lower than that of steel. Using aluminum profiles to manufacture masts can significantly reduce the weight of the vessel, improve its speed, and increase fuel efficiency.

2.Strong Corrosion Resistance: Aluminum alloys have excellent corrosion resistance, allowing them to be used in marine environments for long periods without significant corrosion, thus extending the lifespan of the ship.

3.High Strength: While aluminum profiles are lighter than steel, their strength remains very high, enabling them to withstand various loads and meet the operational needs of masts.

4.Easy to Process and Weld: Aluminum alloys have good workability and weldability, making it easier to manufacture complex-shaped mast structures.

Applications

5052, 5083 Aluminum Sheets: These materials are often used for the mast bases of large yachts, offering excellent corrosion resistance and welding performance.

6061, 6082 Marine-Grade Aluminum Profiles: These high-strength, lightweight aluminum alloys are commonly used in mast bases of large commercial vessels as well as in the hull frames of medium and small commercial ships. They have outstanding mechanical properties and corrosion resistance.

OEM Factory Customization

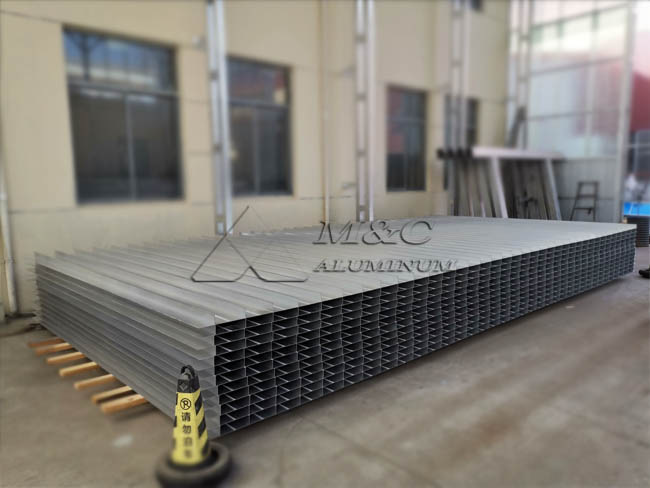

MC Aluminum specializes in producing a wide range of standard profiles, including aluminum square tubes, aluminum rectangular tubes, aluminum round tubes, and seamless pipes, and offers custom processing for special-shaped profiles.

MC Aluminum has advanced production equipment and rich manufacturing experience, enabling the company to customize various specifications and models of aluminum profiles based on customer requirements. For marine-grade anodized aluminum profiles, such as 5083, 6061, and 6082, the OEM factory can produce them based on customer-provided drawings or samples, ensuring the quality and performance of the products meet the customer's specifications.