When it comes to building ships and offshore structures, material selection is critical. The harsh marine environment—featuring saltwater corrosion, wave impact, temperature fluctuations, and long-term heavy loading—demands materials with excellent corrosion resistance, high strength, weldability, and fatigue performance.

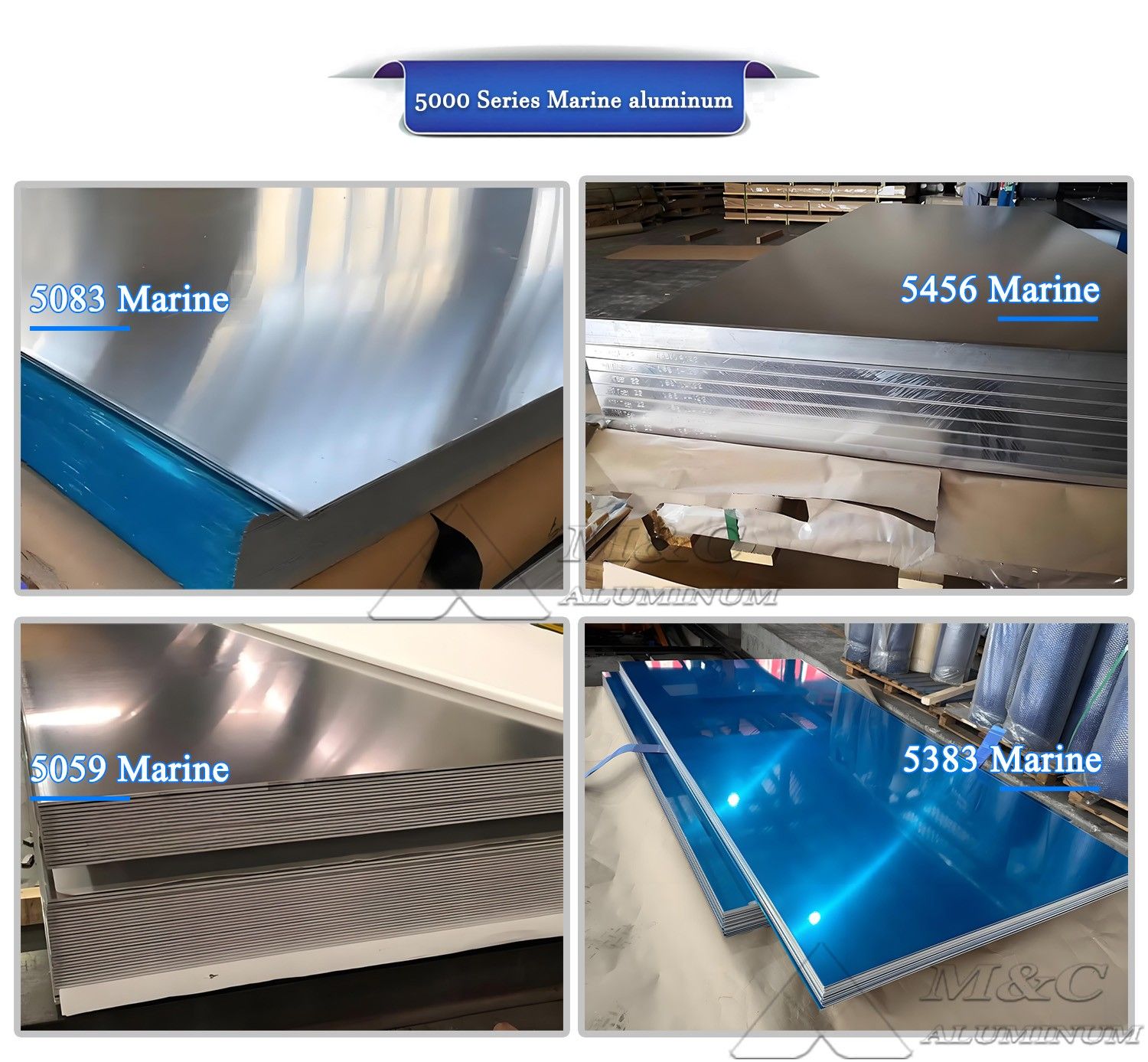

This is why 5000 series marine aluminum alloys have become the top choice in modern shipbuilding. Among them, 5059, 5083, 5383, and 5456 are the most trusted alloys, thanks to their stable performance, outstanding properties, and versatile applications in ship hulls, deck walls, and offshore engineering components.

But what are the differences between these alloys? Which one best suits your vessel or project?

Let’s break them down below:

5000 series marine aluminum plates sheets

1. 5059 Marine Aluminum Plate – For High-Performance Ships and Aerospace Applications

5059 is a high-strength Al-Mg alloy with exceptional corrosion resistance and superior post-weld strength retention. It is widely used in naval vessels and high-performance commercial ships.

Common Applications:

Navy ships and patrol boats

High-speed ferries and cruise ship hulls

Superstructures for warships

Amphibious vehicles and landing crafts

Structural armor and deck panels

Marine Advantages:

High Strength: Outperforms 5083 and even some mild steels in tensile strength, allowing for greater load capacity.

Excellent Corrosion Resistance: Outstanding resistance to saltwater and humid environments, extending service life.

Lightweight Design: Low density supports vessel weight reduction and improves fuel efficiency.

Good Weldability: Maintains strong mechanical properties after welding.

2. 5083 Marine Aluminum Plate – Industry Standard for Shipbuilding

5083 is a classic marine-grade aluminum alloy known for its balanced strength and corrosion resistance. It is one of the most widely used materials in both civil ships and offshore structures.

Common Applications:

Hulls and decks of ships

Seawater tanks and fuel containers

Superstructures of fishing boats, tugboats, and workboats

Piping systems and water tanks

Offshore oil platforms and marine risers

Marine Advantages:

High Strength and Corrosion Resistance: Performs excellently in marine environments.

Excellent Weldability and Formability: Cost-effective and adaptable to complex designs.

Outstanding Low-Temperature Performance: Retains strength and toughness at cryogenic temperatures, ideal for LNG storage.

3. 5383 Marine Aluminum Plate – Upgraded Version of 5083 (Patented Alloy)

5383 is an enhanced version of 5083, offering 15–20% higher strength, better corrosion resistance, and superior weld performance—ideal for structures requiring strong welded joints.

Key Composition:

Enhanced with zirconium (Zr) to form Al₃Zr precipitates, improving grain structure and corrosion resistance.

Common Applications:

Catamarans and multihull vessels

High-speed boats and luxury yachts

Rigid Inflatable Boats (RIB)oons

Welded marine structures requiring weight reduction

Deckhouses, bulkheads, modular pont

Core Features:

Higher Mg content (4.5–5.2%) than 5083

Stronger resistance to pitting and crevice corrosion

Same weldability as 5083 but with improved strength

Especially suitable for post-weld strength retention

4. 5456 Marine Aluminum Plate – For Heavy-Duty Offshore Structures

5456 aluminum offers high strength and excellent high-temperature performance. It performs well under intense heat and heavy structural loads, making it ideal for sun-exposed or high-load ship components.

Common Applications:

Bulkheads, decks, masts

Structural aluminum supports (H116/H111 temper)

Freshwater and saltwater piping systems

Military landing craft and hovercraft

Offshore oil drilling platforms and floating structures

Marine Advantages:

Very High Strength: Higher than 5083 and 5086, suitable for structural applications.

Superior Corrosion Resistance: Excellent resistance to stress corrosion and pitting.

Good Weldability and Machinability: Easy to process and fabricate.

Stress Corrosion Sensitivity: Requires careful design consideration in high-stress environments.

Marine Aluminum Performance Comparison

| Property | 5059-H321/H116 | 5083-H321/H116 | 5383-H321/H116 | 5456-H321/H116 |

| Tensile Strength (MPa) | 370-450 | 290-350 | 310-380 | 370-440 |

| Yield Strength (MPa) | 250-350 | 125-215 | 150-240 | 270-330 |

| Elongation (%) | 12-16 | 12-16 | 12-18 | 10-15 |

| Hardness (Brinell HBW) | 95-120 | 85-100 | 85-105 | 100-130 |

Key Performance Comparison

| Feature | 5059 | 5083 | 5383 | 5456 |

| Strength | High | Medium | Med-High | High |

| Corrosion Resistance | Excellent | Excellent | Superior | Excellent |

| Weldability | Very Good | Excellent | Excellent | Good |

| Fatigue Resistance | Very High | Medium | High | Very High |

How to Choose the Right Marine Aluminum Alloy?

For military vessels or high-speed boats, choose 5059

For general commercial ships, pontoons, ferries, go with 5083

For superior weld integrity and corrosion resistance, use 5383

For high-strength structural parts in cold or high-load environments, opt for 5456

Conclusion

Each aluminum alloy brings distinct advantages to marine applications. Your best choice depends on your project’s priorities—strength, weldability, weight reduction, or corrosion resistance.

With this guide, you can now confidently choose the right aluminum alloy for your boat, barge, platform, or piping system.

MC Aluminum is a professional manufacturer of 5000 and 6000 series marine-grade aluminum plates, offering strict quality control, customization, sample support, and competitive direct factory pricing. Our products are exported globally and trusted by shipbuilders worldwide.

Original Source: https://www.marinealum.com/a/the-4-best-aluminum-alloys-for-marine-use-5059-5083-5383-5456-plates.html

Tag: 5000 series marine aluminum alloys 6000 series marine aluminum alloys marine grade aluminum plates 5059 marine aluminum 5083 marine aluminum 5383 marine aluminum 5456 marine aluminum marine-grade aluminum marine aluminum supplier