MC Aluminum’s 5083 aluminum plate is a marine-grade alloy renowned for its excellent corrosion resistance and high strength. It is widely used in shipbuilding and performs exceptionally well in harsh marine environments. With outstanding weldability and formability, it is the preferred choice for structural components, ensuring durability under demanding conditions.

Material Characteristics of 5083 H111 Aluminum Plate

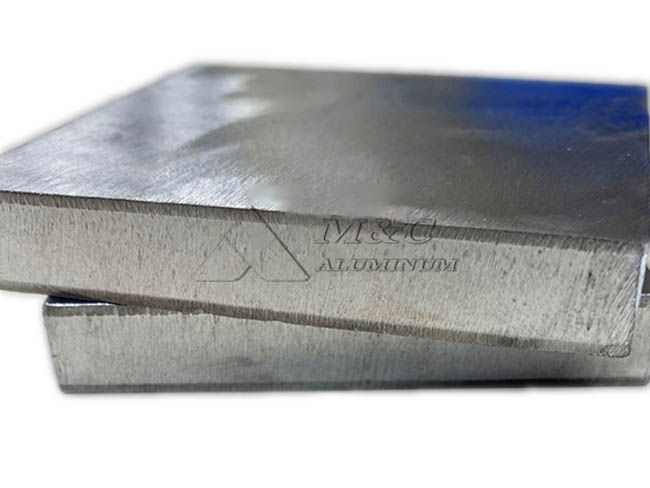

5083 belongs to the Al-Mg alloy series, containing 4.0%–4.9% magnesium and 0.4%–1.0% manganese, combining high strength with superior corrosion resistance. This alloy is non-heat-treatable and relies on work hardening to enhance performance.

H111 Temper Explained

The “H” denotes strain-hardened condition. “111” indicates slight strain hardening after hot working (around 10–15% deformation), retaining excellent ductility (elongation ≥20%) while enhancing tensile strength (110–136 MPa).

The H111 temper represents a balance between strength and ductility, making it ideal for decks and bulkheads that require moderate structural strength and flexibility under ship movement.

International Standards & Quality Assurance

All major global aluminum manufacturers produce 5083 H111 marine aluminum plates in strict compliance with international standards such as BS EN 485-2:2008 and ASTM B209/ASME SB209.

These products often come with certifications from leading classification societies including DNV, NK, CCS, ABS, BV, and LR, ensuring reliability and compliance with the highest standards in ship construction.

Product Specifications

| Alloy | 5083 |

| Temper | H111,O, H112, H116, H321 |

| Thickness | 3mm - 50mm |

| Width | 1000mm - 2600mm |

| Length | Up to 11.8 meters; 5083 coils also available |

| Surface | Smooth, bright, polished, blue PVC film or paper interleaved; 90° bending without cracking |

| Standards | ISO 9001, DNV, LR, ABS, and other certifications |

| MOQ | 1-3 tons |

Chemical Composition of 5083 Aluminum Alloy (% by weight)

| Alloy | Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

| 5083 | Standard value | ≤0.4 | ≤0.4 | ≤0.10 | 0.4-1.0 | 4.0-4.9 | 0.05-0.25 | ≤0.15 | ≤0.25 | Remainder |

Real value | 0.12 | 0.29 | 0.031 | 0.70 | 4.6 | 0.062 | 0.07 | 0.012 | Remainder |

Key Features of 5083 Marine Grade Aluminum Plate

Corrosion Resistance: Exceptional resistance to seawater and chemical environments, making it ideal for hulls, decks, and marine-exposed structures.

High Strength: One of the strongest non-heat-treatable aluminum alloys, providing structural integrity for vessels.

Excellent Weldability: 5083 H111 offers superior weldability, critical for complex marine structures. Recommended filler metals: 5183, 5356, and 5556.

Lightweight: About one-third the density of steel, significantly reducing overall ship weight and improving fuel efficiency—especially beneficial for ferries and hydrofoils.

Good Formability: The H111 temper retains formability while improving strength—suitable for various forming processes.

Low-Temperature Performance: Maintains strength and toughness even at cryogenic temperatures—ideal for LNG storage tanks.

Non-Magnetic: A valuable property for military and marine electronics applications.

Typical Applications in Shipbuilding

5083 H111 marine aluminum plate is widely used in:

Ship hulls: Ideal for high-speed vessels, ferries, and yachts

Decks & superstructures: Providing strong, lightweight platforms

Bulkheads: Internal partitions within ships

LNG spherical tanks: For low-temperature applications

Offshore service vessels and drilling platforms: High corrosion resistance

Portholes, load-bearing plates

Marine containers and container walls

Other components: propellers, pumps, structural brackets

5083 H111 vs H112 vs H116 – What’s the Difference?

H116: Designed for 5xxx-series alloys with ≥4% Mg, providing enhanced corrosion and exfoliation resistance

H111: Annealed with slight strain hardening; lower hardness than H11 but better formability

H112: Used for hot-formed products with properties determined by applicable standards

FAQ – Frequently Asked Questions

Q1: What certifications are available for 5083 marine aluminum plates?

A1: Certified by all major classification societies (BV, LR, ABS, CCS, etc.), meeting international marine construction standards.

Q2: Can 5083 aluminum be bent?

A2: Yes. While stronger than 5052 and 5005, when produced in H111 or O temper, 5083 can be bent 90° without cracking, making it suitable for fuel and water tanks.

Q3: How strong is 5083 aluminum?

A3: With 4.0%–4.9% Mg content, it has very high strength. Its Brinell hardness exceeds 81HB.

Q4: Do you manufacture marine aluminum plates? Do you supply 5083 H321?

A4: Yes. MC Aluminum specializes in 5000 series marine alloys, including 5083, 5052, 5059, 5456, and 5754.

We supply in H111, H116, H321 tempers—all suitable for large-scale vessel construction.