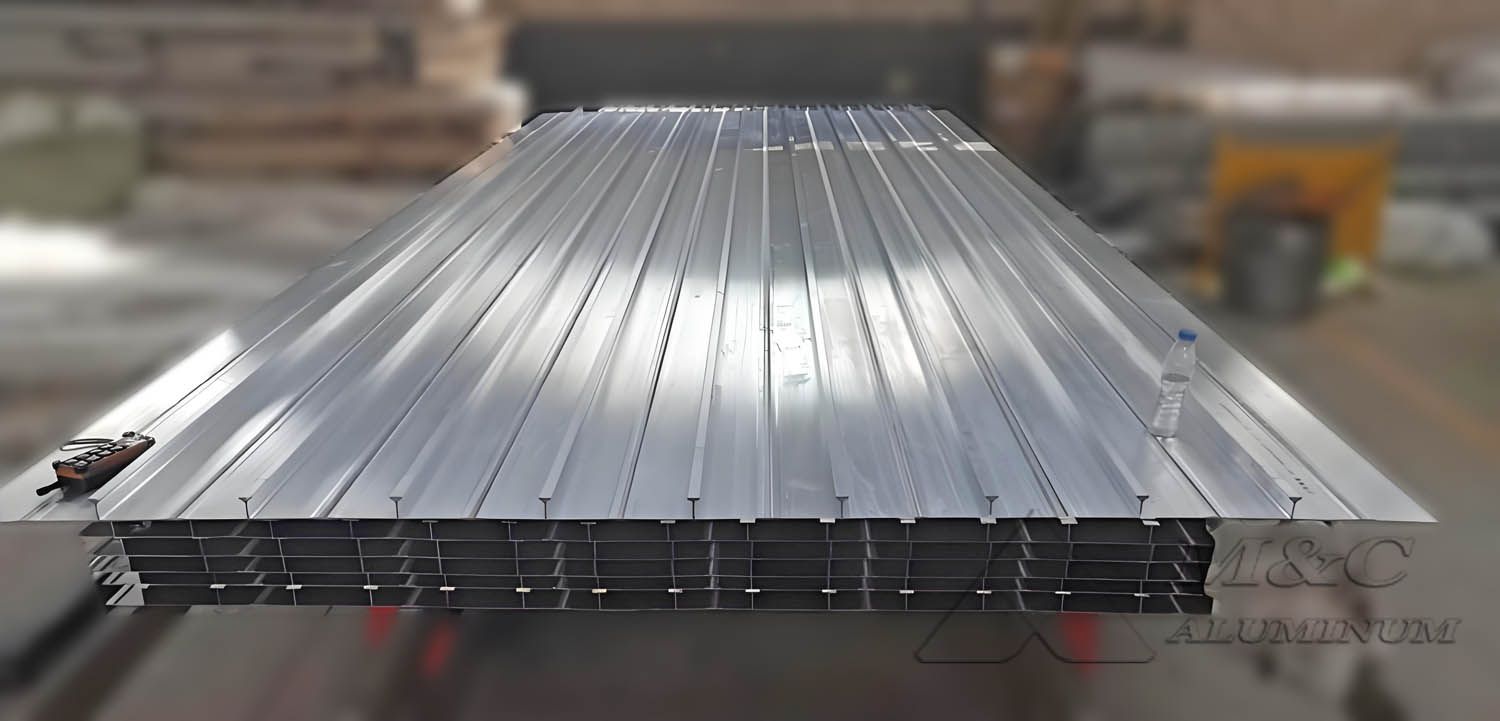

The marine aluminum alloy friction stir welding (FSW) stiffened panel is a specialized aluminum alloy panel used in shipbuilding. With its stiffened structural design, it offers high strength and lightweight advantages, making it widely used in marine vessels, passenger ships, speedboats, and other high-speed ships, as well as in lifeboats, fishing gear boxes, and other marine accessories.

What is a Stiffened Panel?

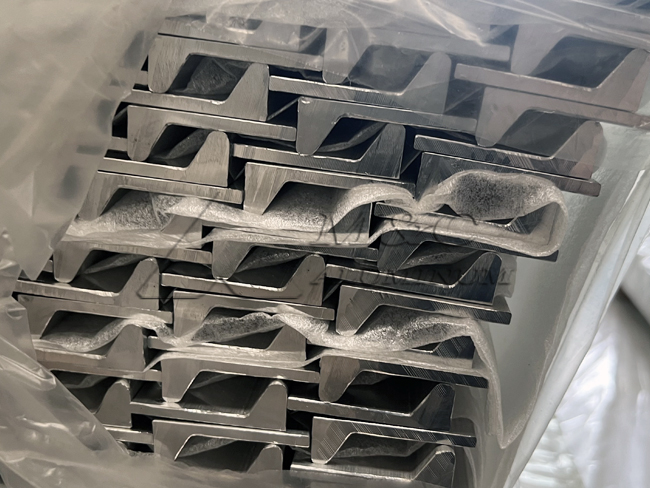

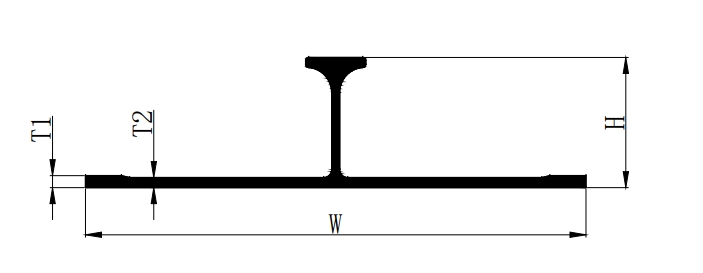

A stiffened panel is a composite structure consisting of a skin panel (faceplate) and stiffeners (rib plates), typically manufactured through extrusion molding or welding assembly. This structure effectively enhances the rigidity of ship hulls or decks while reducing weight.

Application of Friction Stir Welding (FSW) in Stiffened Panels

FSW is a solid-state welding technique, ideal for welding aluminum alloy stiffened panels, especially in areas where thin plates meet thick stiffeners. It significantly reduces the heat-affected zone (HAZ) and ensures high reliability and distortion-free joint welding. Its advantages include:

Low distortion: Compared to fusion welding (MIG/TIG), FSW reduces heat input and minimizes welding deformation.

High strength: The weld joint strength is close to that of the base metal, offering superior fatigue resistance.

Defect-free welding: Avoids common fusion welding defects such as porosity and cracks.

Environmentally friendly: Requires no filler wire or flux, reducing pollution.

Material of Aluminum Alloy Friction Stir Welding Stiffened Panel

Marine aluminum alloys primarily use 5XXX series (Al-Mg) and 6XXX series (Al-Mg-Si) alloys, such as:

5083, 5052: Excellent corrosion resistance and weldability.

6061, 6082: Higher strength but relatively lower corrosion resistance.

Specifications

| Alloy | 5052, 5083, 6061, 6082 |

| Temper | T6 |

| Thickness | 2-10mm |

| Width | <3.3m |

| Length | <12.5m |

Characteristics of Aluminum Alloy Stiffened Panels

1.Lightweight: Lighter than traditional marine steel, reducing overall ship weight and enhancing load capacity and speed.

2.High strength: Provides excellent rigidity and toughness, withstanding harsh marine environments.

3.Corrosion resistance: Performs well in various corrosive environments, ensuring durability and rust-free performance.

4.Good machinability: Special forming processes ensure high precision, making it suitable for complex ship structures.

As a leading manufacturer of marine aluminum processing, MC Aluminum produces FSW panels certified by the ISO9001 quality management system and approved by major classification societies, including the China Classification Society (CCS), Bureau Veritas (BV), and Lloyd’s Register (LR). The company has introduced a large-scale wide aluminum alloy stiffened panel friction stir welding production line, capable of welding lengths up to 15m and thicknesses up to 12mm. With high product performance, competitive pricing, sample availability, and comprehensive after-sales service, MC Aluminum exports its products to multiple countries worldwide.