MC Aluminum is dedicated to providing high-performance aluminum extrusion profiles, widely used in commercial vessels, naval ships, large barges, floating bridges, and various other marine engineering projects. With their lightweight nature, corrosion resistance, and excellent machinability, aluminum profiles can be flexibly formed into a variety of structural components—making them an ideal choice for achieving lightweight, high-strength shipbuilding solutions.

Our aluminum profiles are extensively used in hull structures, masts, deck fittings, and other key components, ensuring durability and reliability even in the harshest marine environments.

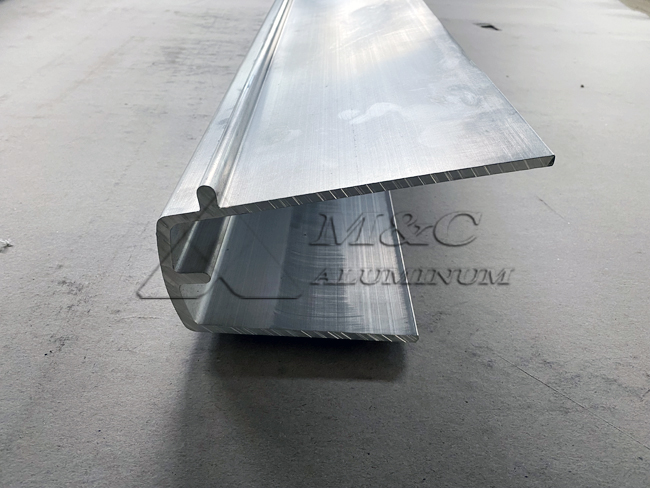

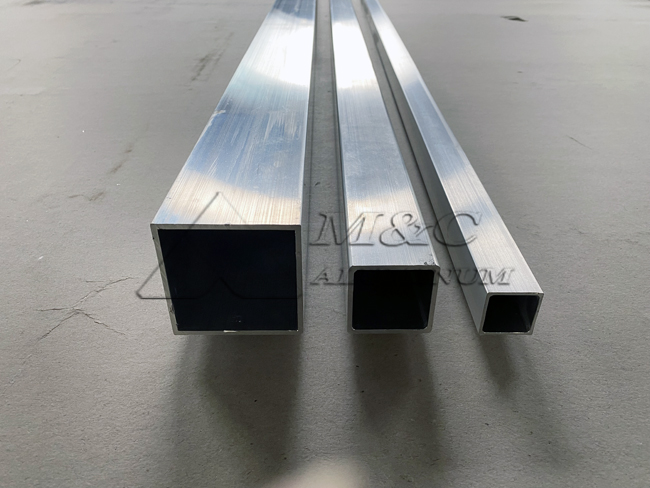

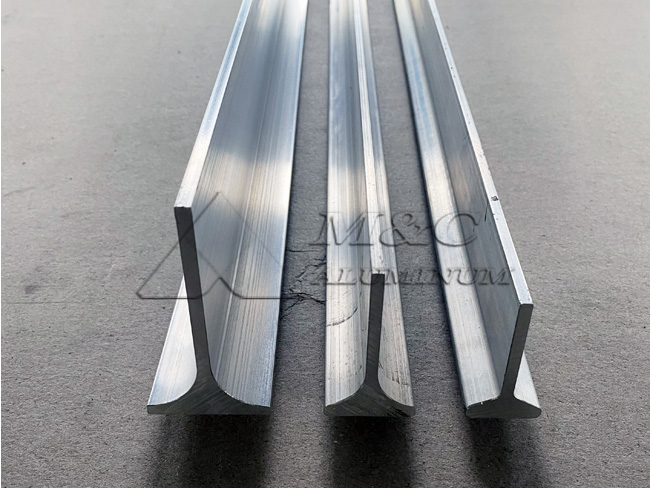

MC Aluminum offers DNV-certified marine aluminum extrusions made from alloys such as 6082-T6, 6061, and 6063. Our product range includes flat aluminum, aluminum tubes, aluminum rods, angular aluminum, square tubes, aluminum troughs, I-type aluminum, aluminum plates, and T-type aluminum. These marine-grade aluminum profiles are engineered to withstand corrosion from seawater and harsh industrial chemicals.

Key Advantages of Marine Aluminum Extrusions:

1.Superior Corrosion Resistance:

Treated with specialized alloying processes and anodization, aluminum profiles can resist chloride ion corrosion in seawater environments, significantly extending the lifespan of ship structures.

2.Lightweight with High Strength:

With a density only one-third that of steel, aluminum alloy structures can reduce overall ship weight by 15%–30%, improve cruising speed by 10%–15%, and cut fuel consumption.

3.Excellent Workability:

Supports various processing techniques such as bending, stamping, and welding. Welded joints retain over 90% of the material’s strength—ideal for complex structural designs.

4.Certified and Trusted:

Fully compliant with DNV certification standards, and rigorously tested to meet IMO (International Maritime Organization) requirements. Internationally recognized for quality and reliability.

Application Scenarios of Marine Aluminum Extrusions:

Hull Structures:

5083-H116/H321 aluminum plates are used in decks, bulkheads, and hull bottoms where high stress is common. Compared to traditional steel plates, they reduce structural weight by up to 30%, enhancing both speed and cargo capacity.Superstructures:

6061-T6 aluminum extrusions are ideal for masts, radar brackets, and window frames, balancing strength with corrosion resistance while minimizing maintenance needs.Special-Purpose Vessels:

LNG carriers use 5083-O temper aluminum in containment systems with DNV-certified welding techniques for leak-proof performance. Polar research vessels utilize 5086-H32 aluminum, which maintains impact toughness even at -60°C.

In addition to our extensive range of extruded profiles, MC Aluminum also supplies DNV-certified marine aluminum plates, and pipe fittings, offering a comprehensive one-stop solution for marine aluminum materials. With a wide variety of products, custom dimensions, fast lead times, sample availability, and global export capabilities, MC Aluminum is your trusted partner in marine-grade aluminum supply.