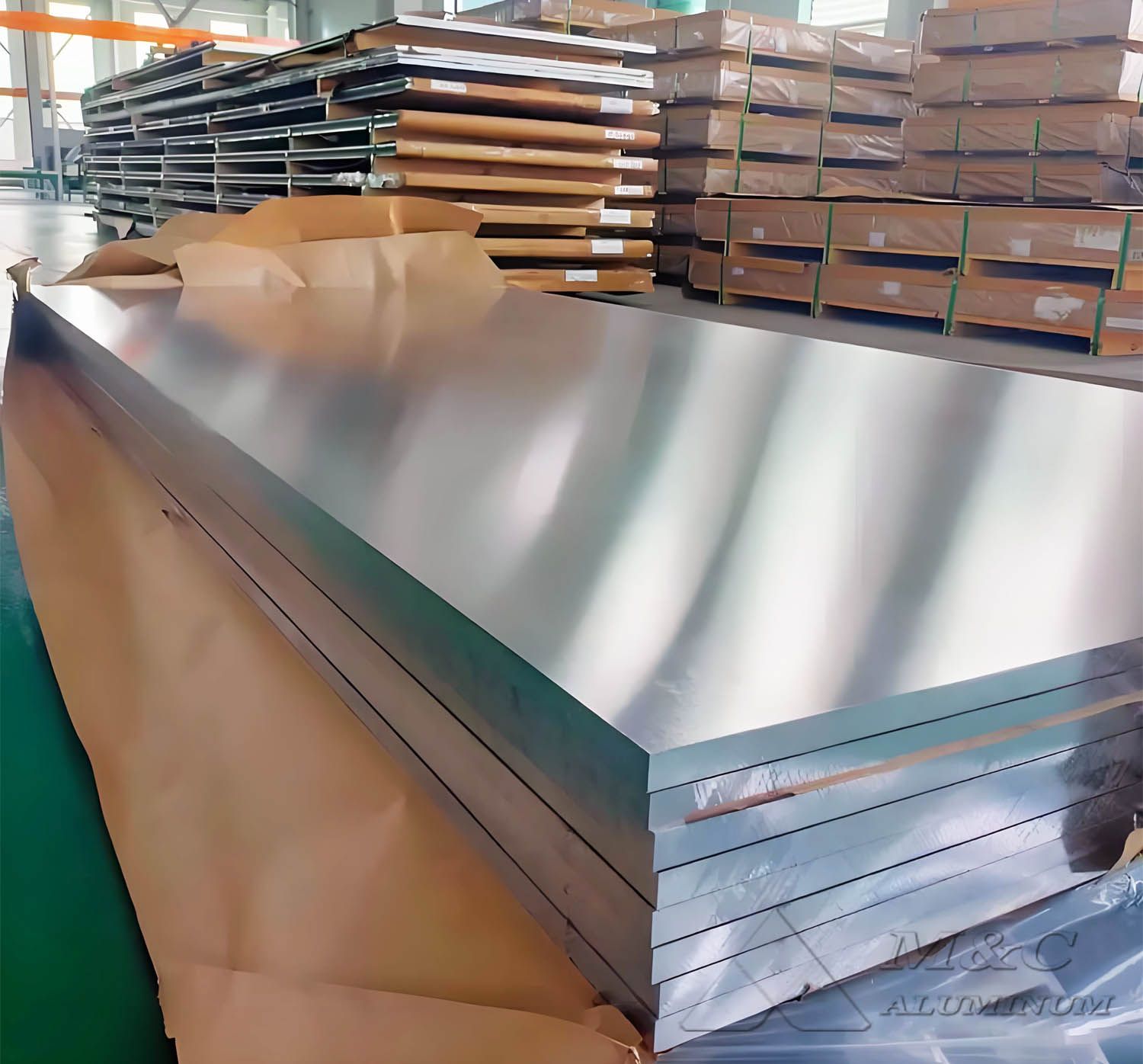

In the field of modern shipbuilding and marine engineering, the choice of materials is crucial. Faced with the strong corrosiveness of seawater, harsh environmental conditions and the need for lightweight structures, 5083-H112 marine aluminum alloy plate has become an ideal choice for shipbuilding with its excellent performance.

5083-H112 aluminum alloy is a high-strength, corrosion-resistant marine aluminum alloy plate, which is widely used in shipbuilding, marine engineering and other environments that require corrosion resistance and high strength. It meets the certification requirements of various classification societies (CCS, DNV, ABS, LR, etc.).

5083 Marine Aluminum Alloy Plate H112 Tempering State Advantages

5083 aluminum alloy plate has undergone a specific heat treatment process (H112 state), which further improves the hardness and strength while maintaining the original excellent corrosion resistance. This heat treatment process not only enhances the mechanical properties of the aluminum alloy plate, but also enables it to show higher corrosion resistance and durability when facing heavy loads and complex stress environments.

5083-H112 marine grade aluminum plate features

1. Excellent corrosion resistance: It can be used for a long time in seawater and high humidity environments, and is not prone to pitting and stress corrosion cracking.

2. Good welding performance: It is suitable for various welding methods such as TIG and MIG, with less strength loss after welding and stable structure.

3. High strength and good plasticity: While ensuring strength, it has good ductility and impact toughness, and is suitable for the processing of complex structural parts.

4. Lightweight design: Compared with traditional steel, 5083-H112 aluminum alloy has a low density, making the ship structure lighter and improving fuel economy.

International classification society certification: quality assurance

Due to the strict requirements of ship and marine engineering on material performance, 5083-H112 aluminum alloy plates need to be certified by major global classification societies to ensure that they meet international standards. At present, the alloy plate can obtain certification from the following authoritative organizations:

CCS (China Classification Society)

DNV (Det Norske Veritas)

ABS (American Bureau of Shipping)

LR (Lloyd's Register)

BV (Bureau Veritas)

GL (Germanischer Lloyd)

These certifications guarantee the safe application of 5083-H112 marine aluminum alloy plate in shipbuilding, offshore floating structures, pressure vessels and other fields.

Application scenarios of 5083 marine grade aluminum plate

Hull structure: 5083-H112 marine aluminum alloy plate is widely used in the manufacture of hulls, decks, and bulkheads of ships, cargo ships, yachts, etc., to improve corrosion resistance and reduce hull weight.

Offshore platform: In structures such as offshore drilling platforms and wind power infrastructure, the alloy plate can withstand the test of harsh marine environments.

Storage tanks and pressure vessels: Its good corrosion resistance makes it an ideal material for containers such as LNG storage tanks and oil tanks.

Rail transit and automobile manufacturing: In the manufacturing of high-speed rail, light rail and special vehicles, 5083-H112 aluminum alloy is used in the body structure to improve safety and durability.