In the process of shipbuilding, the selection of materials is directly related to the performance, safety and life of the ship. 5083 marine aluminum alloy sheets have become one of the important materials in the shipbuilding industry with their superior performance.

Definition of 5083 marine aluminum sheets

5083 aluminum alloy belongs to the aluminum-magnesium alloy series and is a non-heat-treated strengthened aluminum alloy with high strength and excellent corrosion resistance. Its main chemical components include aluminum (Al) and magnesium (Mg), and a small amount of manganese (Mn), chromium (Cr) and other elements are added. This alloy has excellent seawater corrosion resistance and good welding performance, so it is widely used in the construction of ship hulls, decks, bulkheads and other parts, as well as offshore platform structural parts, military ship structural parts, etc.

Advantages of 5083 marine aluminum plates

1.High strength and light weight characteristics: high yield strength and tensile strength, reducing hull weight, saving energy consumption, and increasing load capacity.

2.Excellent corrosion resistance: high magnesium content, seawater corrosion resistance, suitable for hulls and underwater components.

3.Excellent mechanical properties: high strength and fatigue resistance, resistant to ocean waves and harsh environments.

4.Good processing formability: easy to cold process and weld, suitable for complex structure manufacturing.

5.Safe and environmentally friendly: no combustion when exposed to fire, high recycling rate, in line with environmental protection requirements, reducing resource waste and environmental pollution.

6.High cost performance: slightly higher initial cost, but durability and low maintenance cost make the overall cost of use more advantageous.

Classification society certified aluminum sheet specifications

| Alloy | 5083 |

| Temper | H116, H321, H111, H112, etc |

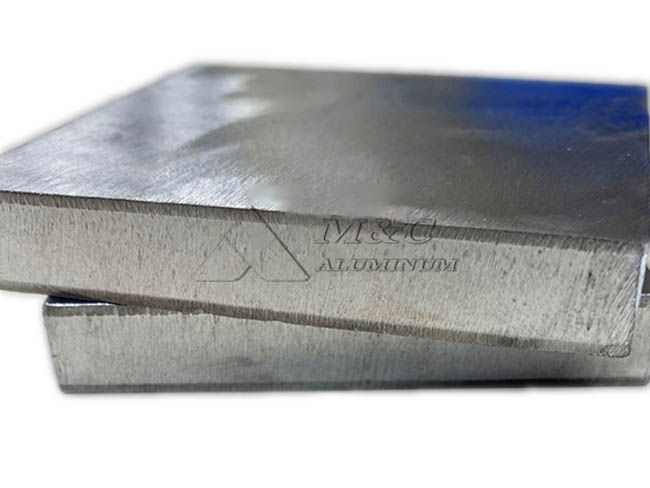

| Thickness | 3-50mm |

| Width | 100-2650mm |

| Length | 100-16000mm |

| Processing services | bending, uncoiling, welding, stamping, cutting |

| Certification | CCS, DNV, NK, CCS, ABS, BV, LR, KR |

Chemical composition of 5083 marine aluminum sheet (%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Other:Each | Other:Total | Al |

| 5083 | 0.4 | 0.4 | 0.1 | 0.4-10 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | 0.05 | 0.15 | remainder |

Material selection requirements for 5083 marine aluminum alloy sheet

In order to meet the use needs of ships in complex environments, the selection of 5083 aluminum alloy sheets must meet the following requirements:

1. Excellent corrosion resistance

Ships are in contact with seawater for a long time, and materials with excellent corrosion resistance must be used. The salt spray and pitting resistance of 5083 aluminum alloy are very outstanding, which can effectively extend the service life of ships and reduce oiling costs.

2. High strength and light weight

(1) Specific strength and specific modulus: The structural strength and size of a ship are closely related to the yield strength and elastic modulus of the material. 5083 aluminum alloy has high specific strength and specific modulus, which means that it has sufficient strength to support the structure of the ship while maintaining its light weight.

(2) Density: Aluminum alloy has a low specific gravity. Using 5083 aluminum alloy can reduce the weight of the hull, save energy, and increase the load capacity.

3. Excellent welding performance

A large number of welding operations are required during ship construction. The welding performance of 5083 aluminum alloy plates is excellent. The mechanical properties after welding are maintained well and cracks are not easy to appear.

4. Low temperature performance

In extremely cold environments, the material is prone to fracture due to increased brittleness. 5083 aluminum alloy has good low temperature toughness and can still maintain good mechanical properties at low temperatures, which is particularly suitable for use in polar ships.

5. Compliance with international certification standards

5083 marine aluminum alloy sheets must comply with the certification of international classification societies (such as CCS, DNV, ABS, etc.) to ensure the quality and reliability of the material.

Application scenarios

5083 marine aluminum alloy sheets are widely used in various types of ships, such as:

1.Cargo ships and tankers: used to manufacture hulls and decks.

2.Passenger ships and yachts: used for lightweight structural design.

3.Military ships: used for parts that require high strength and corrosion resistance.

4.Polar research ships: suitable for low temperature environments.

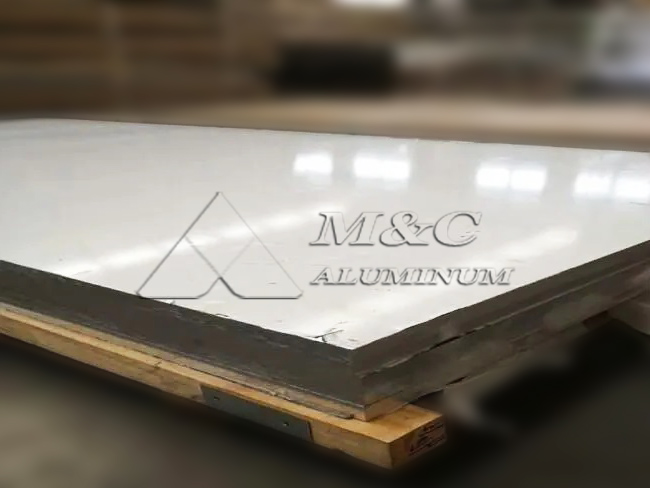

5083 marine aluminum alloy sheets, with their excellent performance, meet the strict requirements of shipbuilding for material strength, lightweight, corrosion resistance and other aspects, and have become an important choice in modern ship materials. The marine aluminum sheets produced by MC Aluminum are certified by classification societies. The surface of the aluminum sheets has no oil spots, no waves, no scratches, no roller marks, neat cutting edges, and no burrs; they are exported overseas with short delivery times and favorable prices.